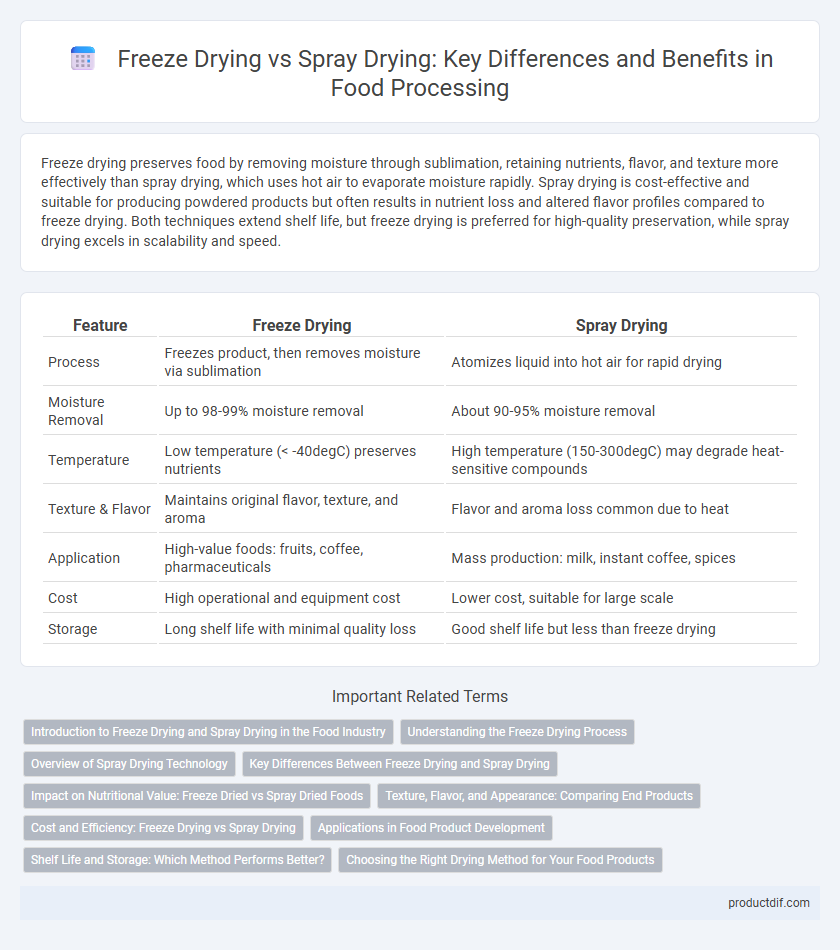

Freeze drying preserves food by removing moisture through sublimation, retaining nutrients, flavor, and texture more effectively than spray drying, which uses hot air to evaporate moisture rapidly. Spray drying is cost-effective and suitable for producing powdered products but often results in nutrient loss and altered flavor profiles compared to freeze drying. Both techniques extend shelf life, but freeze drying is preferred for high-quality preservation, while spray drying excels in scalability and speed.

Table of Comparison

| Feature | Freeze Drying | Spray Drying |

|---|---|---|

| Process | Freezes product, then removes moisture via sublimation | Atomizes liquid into hot air for rapid drying |

| Moisture Removal | Up to 98-99% moisture removal | About 90-95% moisture removal |

| Temperature | Low temperature (< -40degC) preserves nutrients | High temperature (150-300degC) may degrade heat-sensitive compounds |

| Texture & Flavor | Maintains original flavor, texture, and aroma | Flavor and aroma loss common due to heat |

| Application | High-value foods: fruits, coffee, pharmaceuticals | Mass production: milk, instant coffee, spices |

| Cost | High operational and equipment cost | Lower cost, suitable for large scale |

| Storage | Long shelf life with minimal quality loss | Good shelf life but less than freeze drying |

Introduction to Freeze Drying and Spray Drying in the Food Industry

Freeze drying and spray drying are pivotal dehydration techniques in the food industry, utilized for preserving nutrients and extending shelf life. Freeze drying, or lyophilization, removes moisture by sublimating ice under low temperature and pressure, ideal for retaining flavor, texture, and bioactive compounds. Spray drying converts liquid foods into powders through rapid drying with hot air, commonly applied for dairy products, coffee, and powdered flavorings due to its efficiency and scalability.

Understanding the Freeze Drying Process

Freeze drying preserves food by removing moisture through sublimation, converting ice directly to vapor under low temperature and pressure conditions, which retains flavor and nutrients more effectively than spray drying. This method involves freezing the product, reducing pressure in a vacuum chamber, and applying controlled heat to enable sublimation, minimizing thermal degradation and oxidation. Freeze drying is ideal for preserving heat-sensitive foods, maintaining texture and extending shelf life without the need for preservatives.

Overview of Spray Drying Technology

Spray drying technology involves converting liquid food products into powder by rapidly drying with hot gas, preserving flavor and nutritional content. This method is widely used for products like milk powder, coffee, and egg powder due to its ability to create uniform, easily rehydrated powders. Spray drying offers advantages in scalability and product stability compared to freeze drying, though it may cause some heat-sensitive nutrient loss.

Key Differences Between Freeze Drying and Spray Drying

Freeze drying preserves food by sublimating ice under low pressure, maintaining nutritional quality, flavor, and texture with minimal heat exposure, while spray drying uses high temperatures to rapidly evaporate moisture from liquid food into powder form, often resulting in slight nutrient loss. Freeze drying typically produces lightweight, porous products ideal for long-term storage, whereas spray drying generates fine powders suited for instant mixing and easy transport. The choice depends on the food matrix, desired shelf life, and cost-efficiency, with freeze drying being more energy-intensive but superior in preserving delicate compounds.

Impact on Nutritional Value: Freeze Dried vs Spray Dried Foods

Freeze drying preserves up to 90-95% of nutrients by removing moisture through sublimation at low temperatures, maintaining the integrity of vitamins, minerals, and antioxidants. Spray drying, which uses high heat to evaporate moisture quickly, can cause significant nutrient degradation, especially of heat-sensitive compounds like vitamin C and certain B vitamins. As a result, freeze-dried foods retain higher nutritional value compared to spray-dried alternatives, making them ideal for preserving quality in functional and health-focused food products.

Texture, Flavor, and Appearance: Comparing End Products

Freeze drying preserves the original texture of food by maintaining its cellular structure, resulting in a light, porous, and crispy end product, unlike spray drying, which creates a fine, powdery texture by rapidly evaporating moisture. Flavor retention is superior in freeze drying as it minimizes heat exposure, preserving volatile compounds and natural taste, whereas spray drying often leads to flavor degradation due to high thermal processing. Appearance-wise, freeze-dried foods retain their natural shape and color, offering a more visually appealing and recognizable product compared to the uniform, amorphous powder produced by spray drying.

Cost and Efficiency: Freeze Drying vs Spray Drying

Freeze drying incurs higher operational costs due to extensive energy consumption and longer processing times, making it less cost-effective for large-scale food production compared to spray drying. Spray drying offers superior efficiency with rapid moisture removal and lower energy usage, translating into reduced production expenses and faster throughput. Despite higher upfront equipment investment, spray drying remains the preferred method for mass-producing powdered food products where cost and efficiency are critical factors.

Applications in Food Product Development

Freeze drying preserves the cellular structure and nutrients of fruits, vegetables, and full meals, making it ideal for high-quality, shelf-stable snacks, instant coffee, and ready-to-eat meals. Spray drying is widely used for producing powdered dairy products, flavorings, and infant formulas by rapidly drying liquid ingredients into fine powders. Both technologies enhance food product development by optimizing texture, flavor retention, and shelf life in different food categories.

Shelf Life and Storage: Which Method Performs Better?

Freeze drying significantly extends shelf life by removing moisture at low temperatures, preserving nutrients and flavors while preventing microbial growth during storage. Spray drying, though faster and cost-effective, results in a product with higher residual moisture, leading to a shorter shelf life and greater susceptibility to oxidation. For long-term storage, freeze drying outperforms spray drying by maintaining product stability and quality over several years.

Choosing the Right Drying Method for Your Food Products

Choosing the right drying method for food products depends on the desired texture, shelf life, and nutritional retention. Freeze drying preserves flavor, color, and nutrients by sublimating ice under low temperature and pressure, making it ideal for high-quality, sensitive foods like fruits and pharmaceuticals. Spray drying is faster and more cost-effective, suitable for liquid foods and powders such as milk, coffee, and egg products, but may cause some loss of volatile compounds and nutrients.

Freeze Drying vs Spray Drying Infographic

productdif.com

productdif.com