Polished concrete offers a durable, low-maintenance flooring solution with a sleek, natural finish that resists scratches and stains, making it ideal for pet owners seeking long-lasting protection. Epoxy flooring provides a seamless, high-gloss surface that is highly resistant to moisture, chemicals, and wear, ensuring easy cleanup of pet accidents and spills. Both options enhance durability and hygiene while maintaining aesthetics, but polished concrete tends to be more breathable, whereas epoxy offers greater resistance to surface damage.

Table of Comparison

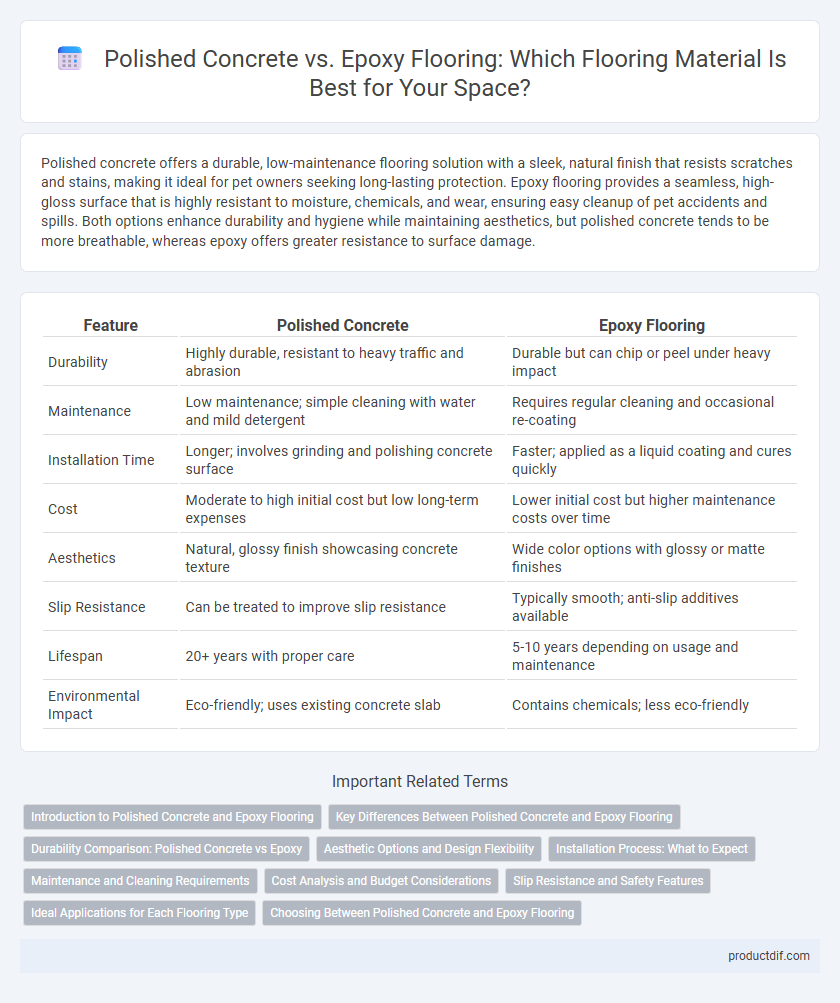

| Feature | Polished Concrete | Epoxy Flooring |

|---|---|---|

| Durability | Highly durable, resistant to heavy traffic and abrasion | Durable but can chip or peel under heavy impact |

| Maintenance | Low maintenance; simple cleaning with water and mild detergent | Requires regular cleaning and occasional re-coating |

| Installation Time | Longer; involves grinding and polishing concrete surface | Faster; applied as a liquid coating and cures quickly |

| Cost | Moderate to high initial cost but low long-term expenses | Lower initial cost but higher maintenance costs over time |

| Aesthetics | Natural, glossy finish showcasing concrete texture | Wide color options with glossy or matte finishes |

| Slip Resistance | Can be treated to improve slip resistance | Typically smooth; anti-slip additives available |

| Lifespan | 20+ years with proper care | 5-10 years depending on usage and maintenance |

| Environmental Impact | Eco-friendly; uses existing concrete slab | Contains chemicals; less eco-friendly |

Introduction to Polished Concrete and Epoxy Flooring

Polished concrete is a durable flooring option created by mechanically grinding and polishing concrete surfaces to achieve a smooth, glossy finish that enhances light reflectivity and requires minimal maintenance. Epoxy flooring consists of a resin-based coating applied over concrete, providing a seamless, high-gloss surface known for chemical resistance, durability, and customizable colors and textures. Both flooring types offer long-lasting solutions suited for commercial, industrial, and residential spaces, with polished concrete emphasizing natural aesthetics and epoxy focusing on protective and decorative versatility.

Key Differences Between Polished Concrete and Epoxy Flooring

Polished concrete offers a natural, durable surface with a high-gloss finish achieved through mechanical grinding and polishing, making it ideal for heavy traffic areas, while epoxy flooring is a synthetic resin coating known for its flexibility, chemical resistance, and wide range of colors and patterns. Polished concrete requires less maintenance and provides superior abrasion resistance, whereas epoxy flooring is prone to scratches but excels in impact resistance and ease of repair. The key differences also include installation time, with polished concrete being faster to apply and cure, and epoxy requiring a multi-layer process including surface preparation and drying.

Durability Comparison: Polished Concrete vs Epoxy

Polished concrete exhibits high durability due to its dense, hardened surface that resists heavy foot traffic, impact, and abrasion over time. Epoxy flooring offers superior chemical resistance and flexibility but may be prone to chipping or peeling under extreme mechanical stress. When comparing longevity, polished concrete generally outperforms epoxy in high-traffic industrial settings, while epoxy provides enhanced protection in environments exposed to harsh chemicals.

Aesthetic Options and Design Flexibility

Polished concrete offers a sleek, industrial look with variable sheen levels and natural aggregate exposure, enabling customization through staining, dyeing, or scoring for unique patterns. Epoxy flooring provides extensive design flexibility with limitless color choices, decorative chips, metallic effects, and customizable textures suitable for both residential and commercial spaces. Both materials support creative design solutions, but epoxy flooring allows for more vibrant and intricate aesthetic options compared to the natural, subtle elegance of polished concrete.

Installation Process: What to Expect

Polished concrete installation involves grinding and honing the concrete surface to achieve a smooth, reflective finish, typically requiring multiple passes with progressively finer abrasives. Epoxy flooring requires surface preparation through cleaning and etching, followed by applying a primer, base coat, and top coat, with curing times that vary depending on the thickness and formula. Both methods demand professional skill and environmental control to ensure proper adhesion and a durable, high-quality finish.

Maintenance and Cleaning Requirements

Polished concrete requires minimal maintenance, involving periodic dust mopping and occasional damp mopping to preserve its sheen and durability. Epoxy flooring demands more frequent cleaning due to its susceptibility to surface scratches and staining, necessitating gentle scrubbing with non-abrasive cleaners. Both materials benefit from prompt spill cleanup, but epoxy floors may require occasional recoating to maintain their glossy finish and protective properties.

Cost Analysis and Budget Considerations

Polished concrete generally offers a lower initial cost ranging from $3 to $7 per square foot compared to epoxy flooring, which can cost between $5 to $12 per square foot depending on the thickness and quality of epoxy used. Maintenance expenses for polished concrete remain minimal due to its durability and ease of cleaning, whereas epoxy flooring may require periodic reapplication or repairs that increase long-term costs. Budget considerations should include installation complexity, lifespan, and potential downtime, with polished concrete favored for cost-effective, low-maintenance solutions in high-traffic areas.

Slip Resistance and Safety Features

Polished concrete offers moderate slip resistance due to its smooth finish, which can become slippery when wet, but can be enhanced with non-slip additives or surface treatments. Epoxy flooring provides higher slip resistance through customizable textures and coatings that improve traction, making it safer for environments prone to moisture or spills. Both materials can be tailored with anti-slip features, but epoxy's versatility in safety enhancements generally makes it preferable for high-risk areas requiring optimal slip resistance.

Ideal Applications for Each Flooring Type

Polished concrete excels in high-traffic commercial spaces, industrial facilities, and modern residential interiors due to its durability and low maintenance requirements. Epoxy flooring is ideal for environments requiring chemical resistance and vibrant aesthetics, such as hospitals, garages, and warehouses. Selecting polished concrete suits heavy-duty applications, while epoxy flooring is preferred for decorative and protective purposes in specialized settings.

Choosing Between Polished Concrete and Epoxy Flooring

Polished concrete offers a durable, low-maintenance solution with a natural, glossy finish that enhances the inherent texture of the concrete. Epoxy flooring provides a highly customizable, colorful, and chemical-resistant surface ideal for industrial and commercial spaces requiring robust protection. Choosing between polished concrete and epoxy flooring depends on factors such as budget, aesthetic preferences, durability needs, and the specific environment where the flooring will be installed.

Polished Concrete vs Epoxy Flooring Infographic

productdif.com

productdif.com