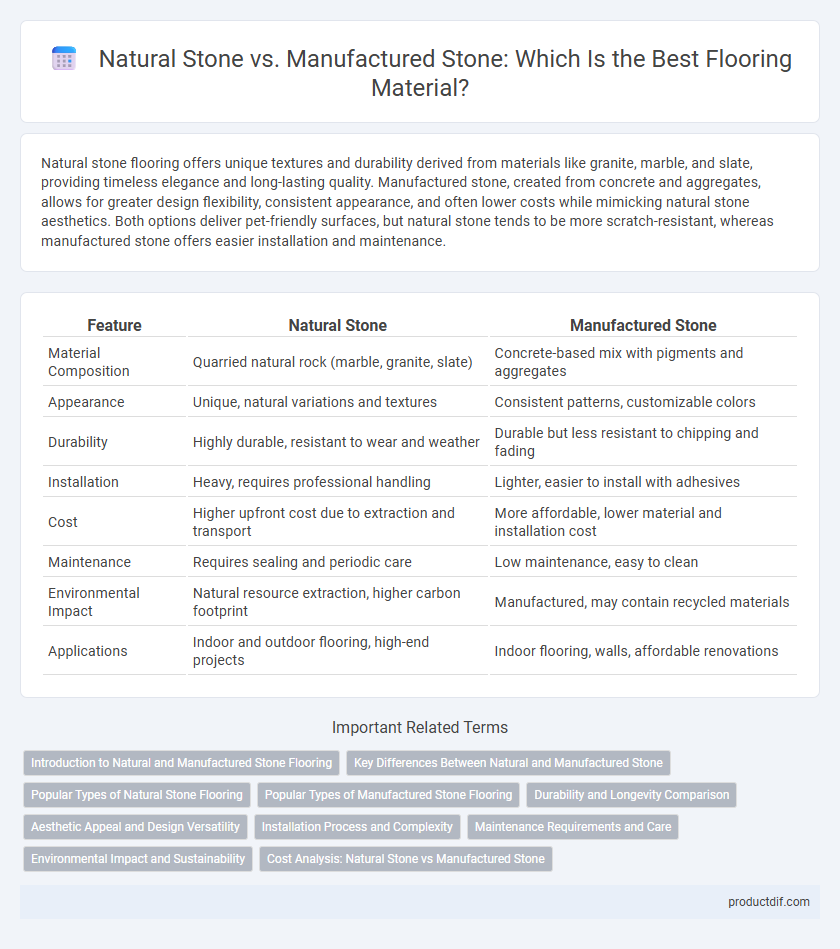

Natural stone flooring offers unique textures and durability derived from materials like granite, marble, and slate, providing timeless elegance and long-lasting quality. Manufactured stone, created from concrete and aggregates, allows for greater design flexibility, consistent appearance, and often lower costs while mimicking natural stone aesthetics. Both options deliver pet-friendly surfaces, but natural stone tends to be more scratch-resistant, whereas manufactured stone offers easier installation and maintenance.

Table of Comparison

| Feature | Natural Stone | Manufactured Stone |

|---|---|---|

| Material Composition | Quarried natural rock (marble, granite, slate) | Concrete-based mix with pigments and aggregates |

| Appearance | Unique, natural variations and textures | Consistent patterns, customizable colors |

| Durability | Highly durable, resistant to wear and weather | Durable but less resistant to chipping and fading |

| Installation | Heavy, requires professional handling | Lighter, easier to install with adhesives |

| Cost | Higher upfront cost due to extraction and transport | More affordable, lower material and installation cost |

| Maintenance | Requires sealing and periodic care | Low maintenance, easy to clean |

| Environmental Impact | Natural resource extraction, higher carbon footprint | Manufactured, may contain recycled materials |

| Applications | Indoor and outdoor flooring, high-end projects | Indoor flooring, walls, affordable renovations |

Introduction to Natural and Manufactured Stone Flooring

Natural stone flooring features materials such as granite, marble, and slate, prized for their unique textures, durability, and timeless elegance. Manufactured stone, often made from concrete and engineered composites, provides a versatile and cost-effective alternative with consistent shapes and colors. Both options offer distinct aesthetic and performance benefits, making them suitable for various interior and exterior applications.

Key Differences Between Natural and Manufactured Stone

Natural stone offers unique patterns and textures formed through geological processes, providing unmatched durability and a high-end aesthetic for flooring applications. Manufactured stone, created from a mixture of cement, aggregates, and pigments, allows for consistent shapes, colors, and easier installation at a lower cost. Key differences include natural stone's variability and strength versus manufactured stone's versatility and affordability, impacting choices in residential and commercial flooring projects.

Popular Types of Natural Stone Flooring

Granite, marble, and slate rank among the most popular types of natural stone flooring due to their durability and unique aesthetic appeal. Limestone and travertine also offer elegant textures and color variations that enhance both traditional and modern interior designs. Natural stone flooring provides superior longevity and a timeless look, setting it apart from manufactured stone options.

Popular Types of Manufactured Stone Flooring

Manufactured stone flooring offers popular types such as cultured marble, concrete stone, and engineered quartz, prized for durability and design flexibility. Cultured marble combines natural marble with resins for a cost-effective, customizable surface, while concrete stone provides a robust, industrial aesthetic ideal for high-traffic areas. Engineered quartz flooring integrates natural quartz with polymers for superior scratch resistance and consistent coloration, making it a preferred choice in residential and commercial applications.

Durability and Longevity Comparison

Natural stone flooring, such as granite, marble, and slate, offers superior durability and can last for decades or even centuries with minimal wear due to its dense composition and natural resistance to scratches and moisture. Manufactured stone, while more affordable and easier to install, generally has a shorter lifespan and is more prone to chipping, fading, and weather-related damage because it is composed of concrete and resin-based materials. Choosing natural stone ensures a longer-lasting investment with greater structural integrity and low maintenance requirements in high-traffic or outdoor areas.

Aesthetic Appeal and Design Versatility

Natural stone offers a unique, timeless aesthetic with rich textures and color variations that enhance any space with authenticity and elegance. Manufactured stone provides greater design versatility through customizable shapes, sizes, and colors, allowing for consistent patterns and tailored installations. Both materials are popular in flooring applications, with natural stone favored for luxury settings and manufactured stone chosen for diverse design options and budget-friendly solutions.

Installation Process and Complexity

Natural stone installation involves precise cutting and fitting due to its irregular shapes and variable thickness, often requiring skilled masons and longer labor time. Manufactured stone offers more uniformity and lighter weight, simplifying handling and enabling quicker, more straightforward installation with basic tools. Both materials demand proper substrate preparation, but natural stone generally poses higher complexity and cost in the installation process.

Maintenance Requirements and Care

Natural stone requires regular sealing and careful cleaning with pH-balanced products to prevent staining and damage, while manufactured stone typically demands less frequent sealing and is more resistant to moisture and stains. Manufactured stone surfaces can be cleaned effectively with mild detergents and do not usually require specialized maintenance products or techniques. Both types benefit from avoiding abrasive cleaners and ensuring proper drainage to extend durability and maintain aesthetic appeal.

Environmental Impact and Sustainability

Natural stone offers exceptional durability and minimal processing, resulting in lower carbon emissions compared to manufactured stone, which involves energy-intensive production and synthetic binders. Quarrying natural stone can disrupt ecosystems but often requires less chemical use and generates fewer pollutants than the manufacturing process of engineered stone. Choosing locally sourced natural stone reduces transportation emissions further, supporting sustainable building practices and reducing overall environmental footprint.

Cost Analysis: Natural Stone vs Manufactured Stone

Natural stone typically incurs higher upfront costs due to quarrying, transportation, and labor-intensive installation, often ranging from $10 to $30 per square foot. Manufactured stone offers a budget-friendly alternative, generally priced between $6 and $15 per square foot, benefiting from factory production and easier installation. Long-term maintenance expenses also favor manufactured stone, as it tends to resist cracking and weathering more effectively, reducing repair costs over time.

Natural Stone vs Manufactured Stone Infographic

productdif.com

productdif.com