Laser-cut wood offers precise, consistent designs ideal for intricate craft projects, while hand-carved wood provides unique, artisanal charm with slight variations in each piece. The speed and efficiency of laser cutting make it suitable for mass production, whereas hand carving requires skilled craftsmanship and time, enhancing the value of bespoke items. Choosing between these methods depends on the desired balance between uniformity and individuality in woodcraft supplies.

Table of Comparison

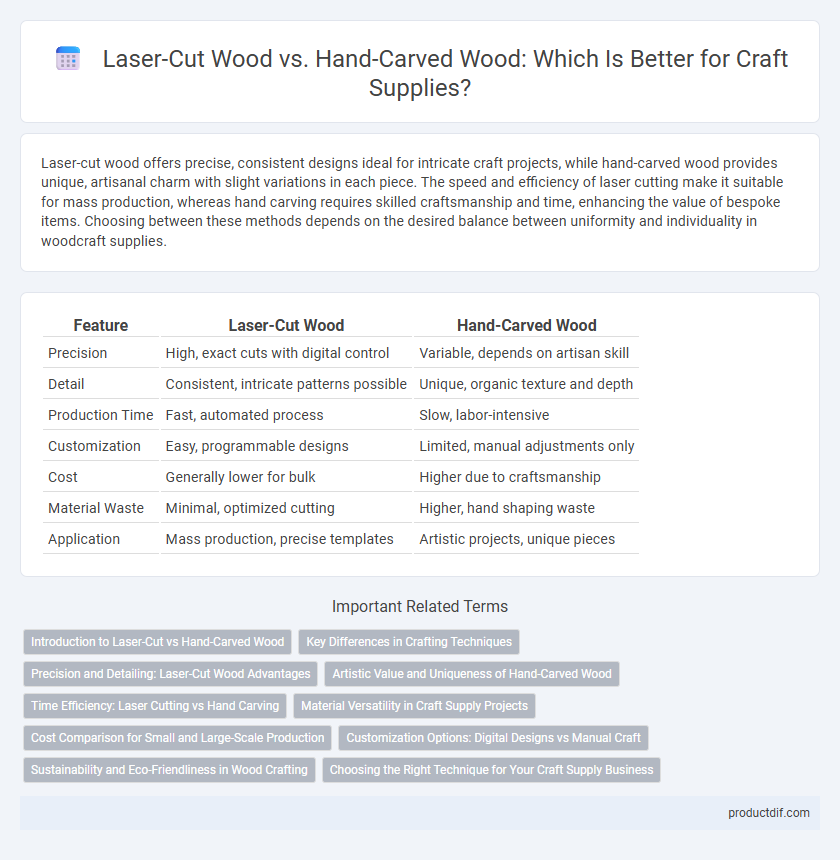

| Feature | Laser-Cut Wood | Hand-Carved Wood |

|---|---|---|

| Precision | High, exact cuts with digital control | Variable, depends on artisan skill |

| Detail | Consistent, intricate patterns possible | Unique, organic texture and depth |

| Production Time | Fast, automated process | Slow, labor-intensive |

| Customization | Easy, programmable designs | Limited, manual adjustments only |

| Cost | Generally lower for bulk | Higher due to craftsmanship |

| Material Waste | Minimal, optimized cutting | Higher, hand shaping waste |

| Application | Mass production, precise templates | Artistic projects, unique pieces |

Introduction to Laser-Cut vs Hand-Carved Wood

Laser-cut wood offers precision and consistency through computer-controlled cutting technology, enabling intricate designs and smooth edges ideal for detailed craft projects. Hand-carved wood showcases traditional craftsmanship, with unique textures and slight imperfections that add character and authenticity to each piece. Choosing between laser-cut and hand-carved wood depends on the desired style, project complexity, and production scale.

Key Differences in Crafting Techniques

Laser-cut wood offers precision and uniformity through computer-controlled cutting technology, enabling intricate and repeatable designs with faster production times compared to hand-carved wood. Hand-carved wood involves skilled craftsmanship that creates unique, detailed textures and organic variations, reflecting the artisan's touch and traditional techniques. Laser cutting excels in mass production and fine detail accuracy, while hand carving emphasizes individuality and tactile depth in each piece.

Precision and Detailing: Laser-Cut Wood Advantages

Laser-cut wood offers unparalleled precision with intricate detailing achievable through computer-controlled technology, enabling exact replication of complex designs. Unlike hand-carved wood, laser cutting eliminates inconsistencies and human error, producing flawless edges and uniform patterns. This technology optimizes efficiency and enhances quality in craft supplies, making laser-cut wood ideal for detailed projects requiring high accuracy.

Artistic Value and Uniqueness of Hand-Carved Wood

Hand-carved wood offers unparalleled artistic value by showcasing the craftsman's individual skill and creativity in each piece, resulting in unique textures and intricate details that cannot be replicated by laser-cutting. Unlike laser-cut wood, which produces uniform and precise designs ideal for mass production, hand-carved wood emphasizes organic imperfections that highlight the wood's natural beauty and character. This uniqueness enhances the aesthetic appeal for collectors and artisans seeking one-of-a-kind, expressive craft supplies.

Time Efficiency: Laser Cutting vs Hand Carving

Laser-cut wood dramatically reduces production time by automating precision cuts, making it ideal for large-scale craft projects requiring consistency and speed. Hand-carved wood demands extensive manual labor and skill, often consuming hours or days to complete intricate designs. The time efficiency of laser cutting supports rapid prototyping and mass customization, whereas hand carving suits unique, artisanal pieces with slower turnaround times.

Material Versatility in Craft Supply Projects

Laser-cut wood offers exceptional precision and consistency, making it ideal for intricate designs in craft supply projects that require uniformity across multiple pieces. Hand-carved wood provides unmatched texture and organic variation, giving each craft item a unique, artisanal quality that appeals to custom and one-of-a-kind creations. Material versatility in craft supply projects benefits from combining laser-cut wood for speed and repeatability with hand-carved wood to enhance aesthetic and tactile appeal.

Cost Comparison for Small and Large-Scale Production

Laser-cut wood offers a cost-effective solution for large-scale production due to its speed, precision, and minimal labor requirement, significantly reducing overall expenses compared to hand-carved wood. Hand-carved wood, while ideal for small-scale, custom projects, incurs higher labor costs and longer production times, making it less efficient for mass manufacturing. For businesses prioritizing scalability and budget, laser-cut wood minimizes material waste and ensures consistent quality, whereas hand-carved methods excel in bespoke craftsmanship at a premium price point.

Customization Options: Digital Designs vs Manual Craft

Laser-cut wood offers precise customization options through digital design files, enabling intricate patterns and consistent replication ideal for detailed craft projects. Hand-carved wood provides unique, one-of-a-kind textures and artistic nuances that reflect the craftsman's skill, allowing for more organic and personalized finishes. Both methods cater to different customization needs: digital laser cutting excels in accuracy and repeatability, while hand carving emphasizes individual artistry and tactile depth.

Sustainability and Eco-Friendliness in Wood Crafting

Laser-cut wood crafting offers higher sustainability by minimizing material waste and reducing energy consumption compared to traditional hand-carving methods. Hand-carved wood often involves more scrap and requires extensive use of manual tools, which can strain resources and increase the environmental footprint. Choosing laser-cut wood enhances eco-friendliness through precision cutting, promoting efficient use of sustainably sourced timber in crafting projects.

Choosing the Right Technique for Your Craft Supply Business

Laser-cut wood offers unmatched precision and consistency, making it ideal for intricate and repetitive designs in craft supply production. Hand-carved wood provides unique, artisanal qualities with natural variations, appealing to customers seeking bespoke or rustic aesthetics. Selecting the right technique depends on your business goals, production volume, and target market preference for precision or craftsmanship.

Laser-cut wood vs Hand-carved wood Infographic

productdif.com

productdif.com