Spray degreasers offer quick application and excellent coverage on flat surfaces, making them ideal for light to moderate grease removal. Foam degreasers cling longer to vertical or irregular surfaces, providing deeper penetration and extended contact time for tougher grease buildup. Choosing between the two depends on the cleaning task, surface type, and desired efficiency.

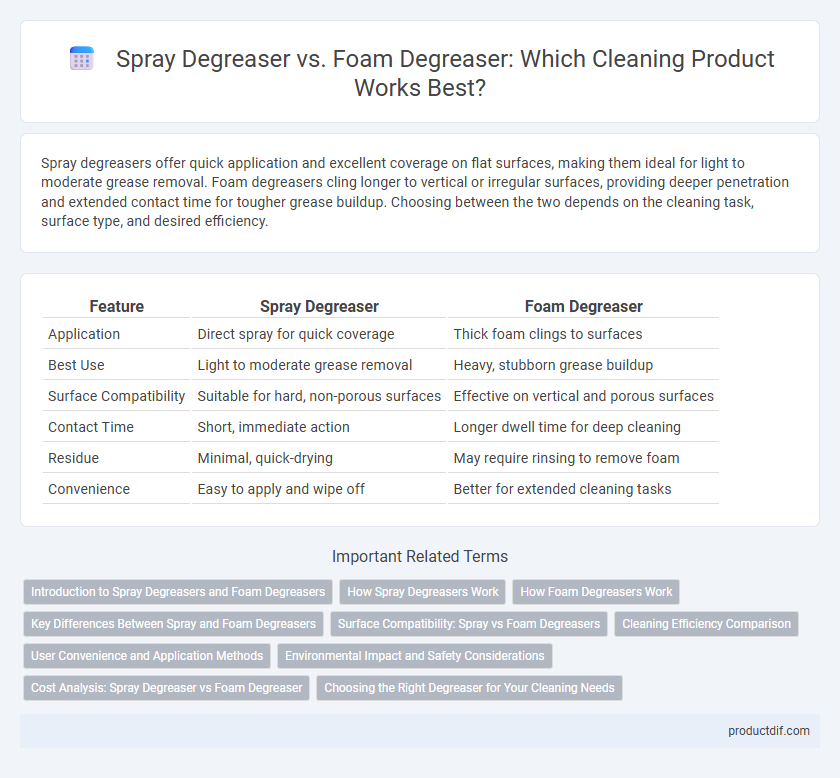

Table of Comparison

| Feature | Spray Degreaser | Foam Degreaser |

|---|---|---|

| Application | Direct spray for quick coverage | Thick foam clings to surfaces |

| Best Use | Light to moderate grease removal | Heavy, stubborn grease buildup |

| Surface Compatibility | Suitable for hard, non-porous surfaces | Effective on vertical and porous surfaces |

| Contact Time | Short, immediate action | Longer dwell time for deep cleaning |

| Residue | Minimal, quick-drying | May require rinsing to remove foam |

| Convenience | Easy to apply and wipe off | Better for extended cleaning tasks |

Introduction to Spray Degreasers and Foam Degreasers

Spray degreasers deliver a targeted and rapid application of solvents and surfactants, effectively breaking down grease and grime on hard-to-reach surfaces with minimal overspray. Foam degreasers generate a dense, clinging foam that prolongs contact time and enhances penetration on vertical or porous surfaces, improving soil lift and reducing runoff. Both formulations optimize industrial and household cleaning performance by adapting to specific surface types and cleaning challenges.

How Spray Degreasers Work

Spray degreasers work by delivering a fine mist of solvent-based or water-based cleaning agents that rapidly dissolve grease, oil, and grime on surfaces. These products often contain surfactants and emulsifiers that break down stubborn residues, allowing easy wipe-off without leaving residue. The spray application ensures even coverage and quick penetration into cracks and crevices for effective degreasing.

How Foam Degreasers Work

Foam degreasers work by creating a thick, clinging foam that adheres to vertical surfaces, allowing active ingredients to penetrate and dissolve grease and grime effectively. The foam's extended contact time boosts cleaning power on tough, baked-on residues in kitchens and industrial settings. Compared to spray degreasers, foam formulations minimize runoff and waste while enhancing safety during heavy-duty cleaning tasks.

Key Differences Between Spray and Foam Degreasers

Spray degreasers deliver a fine mist that quickly penetrates oily surfaces, making them ideal for hard-to-reach areas and light to medium grease removal. Foam degreasers cling to vertical surfaces longer, allowing for deeper cleaning without runoff, which is effective for heavy grease buildup and extended dwell time. The choice depends on surface type, grease level, and application method, with sprays favoring speed and foams emphasizing prolonged contact and thorough degreasing.

Surface Compatibility: Spray vs Foam Degreasers

Spray degreasers excel on smooth, hard surfaces such as kitchen countertops and metal machinery due to their ability to evenly coat and quickly penetrate grease. Foam degreasers offer superior adhesion and cling well to vertical surfaces and porous materials like upholstery or textured walls, allowing extended dwell time for tougher grime removal. Surface compatibility depends on the degreaser's formulation and application method, with sprays preferred for fast, broad coverage and foams for targeted, deep cleaning on uneven or vertical areas.

Cleaning Efficiency Comparison

Spray degreasers offer rapid surface coverage with ease of application, making them effective for quick grease removal on flat or small areas, while foam degreasers provide extended contact time and cling to vertical or uneven surfaces, enhancing deep-cleaning efficiency. Foam degreasers often outperform sprays in breaking down heavy, baked-on grease due to their thicker consistency and longer dwell time, which allows active ingredients to penetrate tougher residues. Cleaning efficiency depends on the application context, with sprays ideal for light, fast degreasing and foams excelling in heavy-duty, persistent grease removal tasks.

User Convenience and Application Methods

Spray degreasers offer user convenience with easy, direct application suitable for quick spot cleaning on various surfaces, allowing precise control over the amount used. Foam degreasers provide extended cling time on vertical or porous surfaces, enhancing effectiveness but often requiring more effort to spread evenly and rinse off. Choice depends on the cleaning task, with sprays favored for fast, targeted degreasing and foams preferred for heavy-duty grease removal in hard-to-reach areas.

Environmental Impact and Safety Considerations

Spray degreasers typically contain volatile organic compounds (VOCs) that contribute to air pollution and pose inhalation risks, whereas foam degreasers often use water-based formulas with lower VOC emissions, reducing environmental harm and improving user safety. Foam degreasers create a thicker barrier that minimizes runoff, decreasing the risk of soil and water contamination compared to spray applications. Choosing foam degreasers enhances workplace safety by limiting aerosol exposure and using biodegradable ingredients that break down more quickly in ecosystems.

Cost Analysis: Spray Degreaser vs Foam Degreaser

Spray degreasers generally cost less upfront due to lower packaging and dispensing expenses, while foam degreasers often require specialized nozzles that increase initial investment. Foam degreasers provide more coverage with less product waste, leading to potential savings in long-term usage despite higher unit costs. Evaluating total cost of ownership must consider product concentration, application efficiency, and surface area to optimize cleaning budgets effectively.

Choosing the Right Degreaser for Your Cleaning Needs

Spray degreasers offer precise application and quick drying times, making them ideal for small surfaces and spot cleaning, while foam degreasers provide thicker coverage that clings to vertical surfaces and penetrates grime for heavy-duty cleaning. Selecting the right degreaser depends on the type of surface, level of grease buildup, and ease of application required. Industrial kitchens and automotive workshops benefit from foam degreasers' deep cleaning power, whereas household maintenance tasks typically favor the versatility and convenience of spray degreasers.

Spray degreaser vs Foam degreaser Infographic

productdif.com

productdif.com