Foaming cleaning products create rich suds that help lift dirt and grease from surfaces, making them ideal for tough stains and greasy messes. Non-foaming cleaners penetrate deeply without leaving residue, offering a streak-free finish perfect for glass, electronics, and delicate surfaces. Choosing between foaming and non-foaming formulas depends on the cleaning task and surface sensitivity, ensuring effective and safe results.

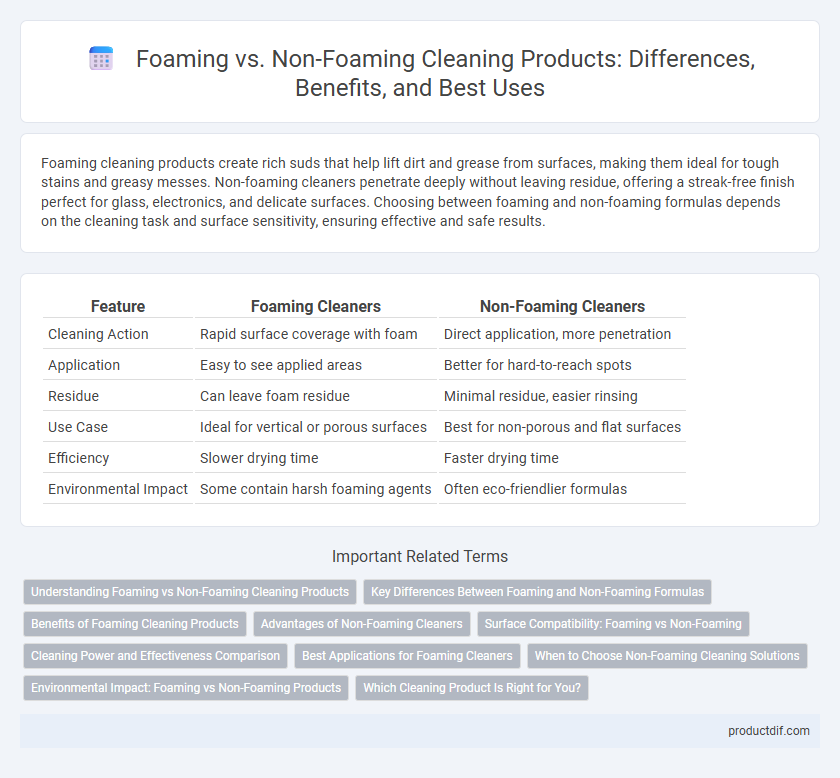

Table of Comparison

| Feature | Foaming Cleaners | Non-Foaming Cleaners |

|---|---|---|

| Cleaning Action | Rapid surface coverage with foam | Direct application, more penetration |

| Application | Easy to see applied areas | Better for hard-to-reach spots |

| Residue | Can leave foam residue | Minimal residue, easier rinsing |

| Use Case | Ideal for vertical or porous surfaces | Best for non-porous and flat surfaces |

| Efficiency | Slower drying time | Faster drying time |

| Environmental Impact | Some contain harsh foaming agents | Often eco-friendlier formulas |

Understanding Foaming vs Non-Foaming Cleaning Products

Foaming cleaning products create bubbles that help lift dirt and grease from surfaces, making them ideal for tasks requiring visible application and rinsing. Non-foaming cleaners, often concentrated liquids, penetrate deeply without residue, preferred for delicate surfaces and industrial settings. Selecting between foaming and non-foaming formulations depends on the cleaning task, surface type, and residue sensitivity.

Key Differences Between Foaming and Non-Foaming Formulas

Foaming cleaning products generate bubbles through surfactants, enhancing surface coverage and visual feedback during use, which aids in grime removal from porous surfaces. Non-foaming formulas typically rely on solvent-based or enzymatic agents for deeper penetration and residue breakdown without creating suds, ideal for heavy-duty or industrial cleaning. The choice between foaming and non-foaming depends on application needs, with foaming preferred for gentle, visible cleaning and non-foaming favored for powerful, residue-free performance.

Benefits of Foaming Cleaning Products

Foaming cleaning products create a rich lather that enhances surface coverage, allowing for more efficient dirt and grease removal. The foam's bubbles lift and trap particles, improving cleaning performance especially on vertical or porous surfaces. This increase in contact time and mechanical action reduces the need for harsh chemicals, promoting safer, eco-friendly cleaning solutions.

Advantages of Non-Foaming Cleaners

Non-foaming cleaners excel in preventing residue build-up, making them ideal for surfaces requiring a streak-free finish such as glass and stainless steel. Their formulation enables faster rinsing and reduced water usage, enhancing efficiency in industrial and commercial cleaning applications. Non-foaming cleaners also minimize the risk of clogging in spray nozzles and cleaning equipment, extending the lifespan of tools and reducing maintenance costs.

Surface Compatibility: Foaming vs Non-Foaming

Foaming cleaning products create bubbles that help lift dirt from porous surfaces without causing damage, making them ideal for delicate materials like upholstery and fabric. Non-foaming cleaners penetrate quickly and work well on hard, non-porous surfaces such as glass, tile, and metal, ensuring thorough cleaning without leaving residue. Choosing between foaming and non-foaming depends on the surface type, with foaming ensuring gentle care for sensitive areas and non-foaming providing effective grime removal on tough surfaces.

Cleaning Power and Effectiveness Comparison

Foaming cleaning products create bubbles that help lift dirt and grease from surfaces, enhancing visibility and spreading action for effective cleaning on fragile or textured materials. Non-foaming cleaners penetrate deeply without residual bubbles, offering superior performance on tough, greasy stains and making them ideal for heavy-duty applications. Both types vary in formulation, but foaming agents often support surface agitation while non-foaming solutions promote concentrated cleaning power and residue-free finishes.

Best Applications for Foaming Cleaners

Foaming cleaners excel in applications requiring deep penetration and extended contact time, such as kitchen grease removal, bathroom tile scrubbing, and automotive engine cleaning. Their rich foam clings to vertical surfaces, improving cleaning efficiency and minimizing runoff. These qualities make foaming cleaners ideal for heavy-duty messes where thorough agitation and prolonged dwell time are critical for stain and soil breakdown.

When to Choose Non-Foaming Cleaning Solutions

Non-foaming cleaning solutions are ideal for use on delicate surfaces such as glass, metal, and electronics where residue and streaking must be minimized. These products are preferred in industrial settings or machinery maintenance because they reduce the risk of clogging and ensure efficient rinsing. Choosing non-foaming cleaners helps maintain equipment longevity and achieves thorough cleanliness without excess suds.

Environmental Impact: Foaming vs Non-Foaming Products

Foaming cleaning products often contain surfactants that generate bubbles, which can lead to higher water usage and potential chemical runoff affecting aquatic ecosystems. Non-foaming products typically use fewer chemicals and require less rinsing, reducing water consumption and minimizing environmental pollution. Choosing non-foaming cleaners supports sustainable practices by lowering the ecological footprint associated with cleaning processes.

Which Cleaning Product Is Right for You?

Foaming cleaning products excel at lifting and trapping dirt and grease, making them ideal for surfaces requiring deep cleaning or visible residue removal, while non-foaming cleaners are better suited for quick wipe-downs and areas where streak-free finishes are essential. Consider the surface type and cleaning purpose: foaming formulas work well on porous or heavily soiled materials, whereas non-foaming options are preferred for glass, stainless steel, and delicate finishes. Your choice depends on desired cleaning intensity and the specific maintenance needs of your environment.

Foaming vs Non-foaming Infographic

productdif.com

productdif.com