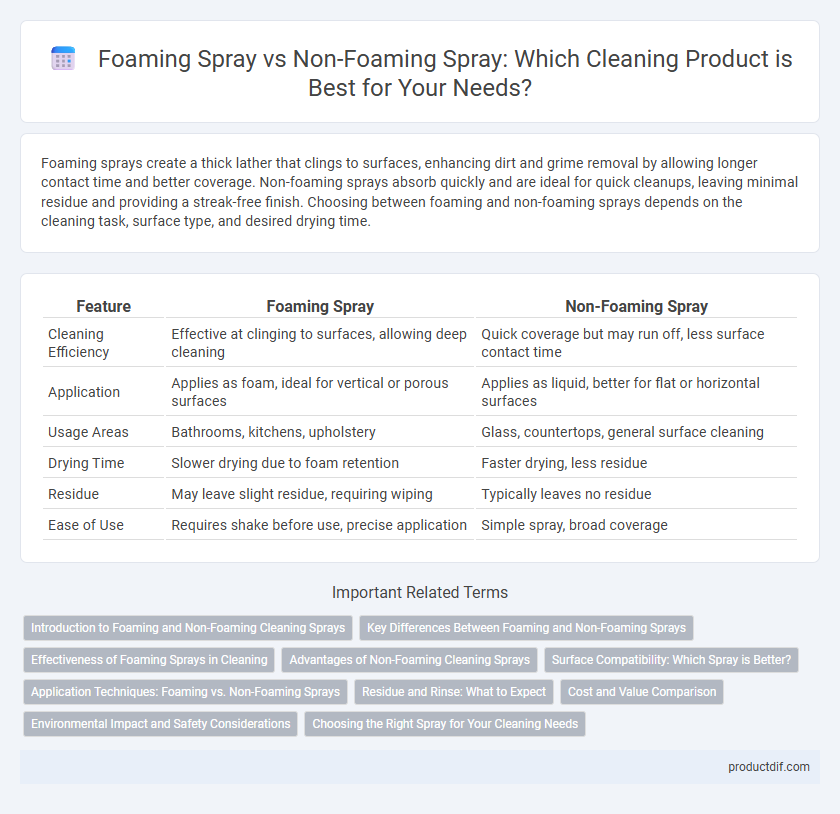

Foaming sprays create a thick lather that clings to surfaces, enhancing dirt and grime removal by allowing longer contact time and better coverage. Non-foaming sprays absorb quickly and are ideal for quick cleanups, leaving minimal residue and providing a streak-free finish. Choosing between foaming and non-foaming sprays depends on the cleaning task, surface type, and desired drying time.

Table of Comparison

| Feature | Foaming Spray | Non-Foaming Spray |

|---|---|---|

| Cleaning Efficiency | Effective at clinging to surfaces, allowing deep cleaning | Quick coverage but may run off, less surface contact time |

| Application | Applies as foam, ideal for vertical or porous surfaces | Applies as liquid, better for flat or horizontal surfaces |

| Usage Areas | Bathrooms, kitchens, upholstery | Glass, countertops, general surface cleaning |

| Drying Time | Slower drying due to foam retention | Faster drying, less residue |

| Residue | May leave slight residue, requiring wiping | Typically leaves no residue |

| Ease of Use | Requires shake before use, precise application | Simple spray, broad coverage |

Introduction to Foaming and Non-Foaming Cleaning Sprays

Foaming sprays create thick bubbles that cling to surfaces, enhancing contact time and improving dirt and grime removal on vertical and porous surfaces. Non-foaming sprays typically offer faster coverage and are ideal for quick wipe-downs, leaving less residue and reducing drying time. Choosing between foaming and non-foaming sprays depends on the cleaning task and surface type, with foaming sprays favored for stubborn dirt and non-foaming for routine maintenance.

Key Differences Between Foaming and Non-Foaming Sprays

Foaming sprays create a thick, visible foam that clings to surfaces, enhancing contact time and improving the removal of dirt and grime, especially on vertical or porous surfaces. Non-foaming sprays produce a liquid mist that spreads quickly and penetrates hard-to-reach areas, making them ideal for quick cleanups and large surface areas. The choice between foaming and non-foaming sprays depends on the cleaning task, with foaming sprays favored for deep cleaning and disinfection, and non-foaming sprays preferred for speed and coverage.

Effectiveness of Foaming Sprays in Cleaning

Foaming sprays enhance cleaning effectiveness by adhering longer to surfaces, allowing active ingredients to break down grime and stains more efficiently than non-foaming sprays. The foam's thick consistency reduces runoff, maximizing contact time and improving soil removal on vertical and porous surfaces. This results in superior performance in tackling tough dirt and providing a more thorough clean in various applications.

Advantages of Non-Foaming Cleaning Sprays

Non-foaming cleaning sprays offer enhanced surface coverage and faster drying times, making them ideal for delicate surfaces and electronics. Their lightweight formula prevents residue buildup, reducing the need for additional wiping and minimizing streaks. These sprays also provide better penetration into crevices and tight spaces, improving overall cleaning efficiency.

Surface Compatibility: Which Spray is Better?

Foaming sprays provide better surface compatibility by adhering longer to vertical and porous surfaces, enabling deeper cleaning without excessive runoff. Non-foaming sprays tend to spread quickly and may be less effective on delicate materials due to faster evaporation, risking streaks or damage. Choosing between foaming and non-foaming sprays depends on the surface type, with foam ideal for textured or absorbent surfaces and non-foam suitable for smooth, non-porous areas.

Application Techniques: Foaming vs. Non-Foaming Sprays

Foaming sprays adhere better to vertical surfaces, allowing cleaning agents to penetrate grime effectively and reduce runoff, making them ideal for bathroom tiles and kitchen appliances. Non-foaming sprays provide quick application and fast drying, suitable for smooth surfaces like glass and countertops where minimal residue is preferred. Choosing between foaming and non-foaming sprays depends on the surface texture and desired cleaning efficiency in different environments.

Residue and Rinse: What to Expect

Foaming sprays typically leave less residue due to their thicker consistency, allowing for easier rinsing and reduced streaking on surfaces. Non-foaming sprays can sometimes leave a thin film that requires more thorough rinsing to avoid sticky or greasy buildup. When choosing between the two, consider that foaming sprays often provide a cleaner finish with less effort in wiping and rinsing.

Cost and Value Comparison

Foaming sprays typically cost more per ounce than non-foaming sprays due to specialized formulas that create dense foam for better surface adherence. Non-foaming sprays offer greater value in bulk purchasing as they cover larger areas quickly with less product. Evaluating cost-effectiveness depends on cleaning tasks; foaming sprays excel in targeted grime removal, while non-foaming options maximize volume and affordability.

Environmental Impact and Safety Considerations

Foaming sprays typically use surfactants and propellants that can contribute to volatile organic compound (VOC) emissions, impacting indoor air quality and the environment, whereas non-foaming sprays often have lower VOC levels and reduced environmental footprint. Safety considerations highlight that foaming sprays may cause more skin or eye irritation due to their concentrated formulas, while non-foaming versions are generally milder and safer for household use. Choosing non-foaming sprays supports eco-friendly cleaning practices by minimizing chemical exposure and waste.

Choosing the Right Spray for Your Cleaning Needs

Foaming sprays provide thicker coverage and longer contact time, making them ideal for cleaning vertical surfaces and tough stains, while non-foaming sprays offer quick evaporation and easier rinsing suitable for general surface cleaning. Selecting the right spray depends on the surface type, cleaning goal, and required dwell time; foaming sprays excel in kitchens and bathrooms with stubborn grime, whereas non-foaming options are preferred for glass and electronics. Understanding these differences ensures more effective and efficient cleaning tailored to specific needs.

Foaming spray vs Non-foaming spray Infographic

productdif.com

productdif.com