Foaming cleaning products create bubbles that help lift dirt and grease from surfaces, making it easier to see the cleaning process and ensuring thorough coverage. Non-foaming products are ideal for applications requiring less residue and faster rinsing, often preferred for delicate surfaces or appliances. Selecting between foaming and non-foaming formulas depends on the specific cleaning task and surface sensitivity.

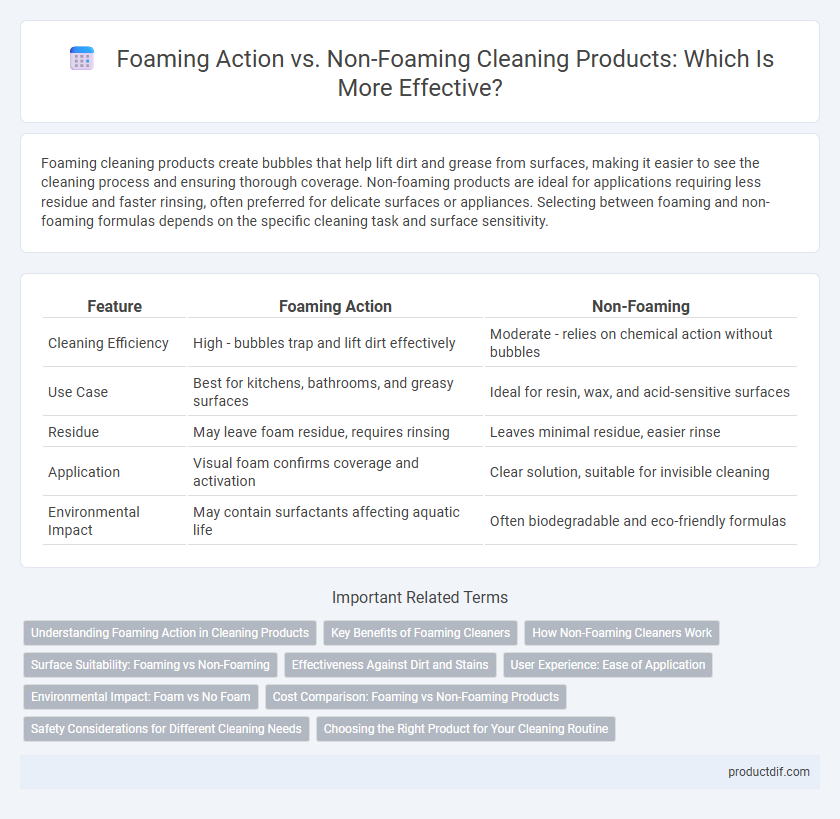

Table of Comparison

| Feature | Foaming Action | Non-Foaming |

|---|---|---|

| Cleaning Efficiency | High - bubbles trap and lift dirt effectively | Moderate - relies on chemical action without bubbles |

| Use Case | Best for kitchens, bathrooms, and greasy surfaces | Ideal for resin, wax, and acid-sensitive surfaces |

| Residue | May leave foam residue, requires rinsing | Leaves minimal residue, easier rinse |

| Application | Visual foam confirms coverage and activation | Clear solution, suitable for invisible cleaning |

| Environmental Impact | May contain surfactants affecting aquatic life | Often biodegradable and eco-friendly formulas |

Understanding Foaming Action in Cleaning Products

Foaming action in cleaning products enhances the distribution of active ingredients across surfaces, improving dirt and grease breakdown by increasing the surface area contact. Non-foaming cleaners rely on chemical formulation rather than bubble creation, making them ideal for applications where residue or streaking must be minimized, such as glass or electronic screens. Understanding foaming action helps consumers choose the right product for their cleaning needs, balancing efficacy and surface compatibility.

Key Benefits of Foaming Cleaners

Foaming cleaners provide enhanced surface coverage and longer contact time, allowing active ingredients to penetrate and break down dirt, grease, and grime more effectively. Their thick foam clings to vertical surfaces, reducing runoff and improving cleaning efficiency, especially on textured or porous materials. This action also minimizes the need for vigorous scrubbing, making foaming products ideal for delicate surfaces and time-saving applications.

How Non-Foaming Cleaners Work

Non-foaming cleaners utilize solvents and surfactants that penetrate and break down grease and dirt without generating bubbles, making them ideal for sensitive surfaces and industrial applications where residue-free cleaning is essential. These cleaners rely on chemical interactions at the molecular level to lift contaminants and facilitate easy rinsing, preserving surface integrity and minimizing cleanup time. Their low-foaming nature reduces the risk of streaks and water spots, enhancing efficiency in high-precision cleaning tasks.

Surface Suitability: Foaming vs Non-Foaming

Foaming cleaning products are ideal for vertical or porous surfaces, as the foam clings and allows for extended contact time, enhancing dirt and grime removal. Non-foaming cleaners excel on smooth, hard surfaces where quick rinsing is crucial, preventing residue buildup and streaks. Selecting the right product based on surface type ensures optimal cleaning efficiency and preserves material integrity.

Effectiveness Against Dirt and Stains

Foaming cleaning products create bubbles that help lift and encapsulate dirt and stains for easy removal, enhancing surface contact and penetration. Non-foaming cleaners often rely on chemical agents to break down grease and grime without the tactile feedback of bubbles, making them effective on heavy-duty stains and hard-to-reach areas. Choosing the right formula depends on the type of surface and the intensity of soil, with foaming action providing visible cleansing dynamics and non-foaming options focusing on deep chemical effectiveness.

User Experience: Ease of Application

Foaming cleaning products enhance user experience by providing visible coverage and allowing easier control during application, which improves precision and reduces waste. Non-foaming cleaners often require more effort to spread evenly and can feel less satisfying due to the lack of tactile feedback. Choosing between foaming and non-foaming depends on the specific cleaning task and personal preference for application ease and effectiveness.

Environmental Impact: Foam vs No Foam

Foaming cleaning products often contain surfactants that can contribute to water pollution and require more water for rinsing, increasing environmental footprint. Non-foaming formulations generally use fewer chemicals and less water, promoting eco-friendliness and reducing wastewater contamination. Choosing non-foaming cleaners can significantly lower the environmental impact by minimizing chemical residues and water consumption during cleaning.

Cost Comparison: Foaming vs Non-Foaming Products

Foaming cleaning products often incur higher manufacturing and packaging costs due to specialized surfactants and dispensing mechanisms, which can translate to increased retail prices. Non-foaming products generally have simpler formulations and standard containers, reducing overall production expenses and offering more budget-friendly options for consumers. When evaluating cost-effectiveness, non-foaming cleaners typically provide better value, especially for high-volume or commercial use scenarios.

Safety Considerations for Different Cleaning Needs

Foaming cleaning products offer visible action that helps target dirt in hard-to-reach areas but may pose inhalation risks if used in poorly ventilated spaces. Non-foaming cleaners reduce respiratory concerns and are often preferred for sensitive surfaces or environments requiring gentle cleaning agents. Choosing between foaming and non-foaming options depends on specific cleaning needs, surface sensitivity, and safety protocols to minimize exposure to irritants.

Choosing the Right Product for Your Cleaning Routine

Foaming cleaning products create a rich lather that helps lift and trap dirt, making them ideal for surfaces that require visible scrubbing and extended contact time. Non-foaming cleaners offer efficient degreasing and quick rinsing, suitable for electronics or smooth surfaces where residue must be minimal. Selecting the right product depends on the surface type, cleaning frequency, and residue sensitivity to optimize effectiveness and safety.

Foaming action vs Non-foaming Infographic

productdif.com

productdif.com