Manual dispensing offers precise control over the amount of cleaning product used, reducing waste but requiring more effort and time. Automatic dispensing ensures consistent, hands-free application, enhancing efficiency and hygiene by minimizing contact with the product. Both methods cater to different user preferences, balancing convenience and control in pet cleaning routines.

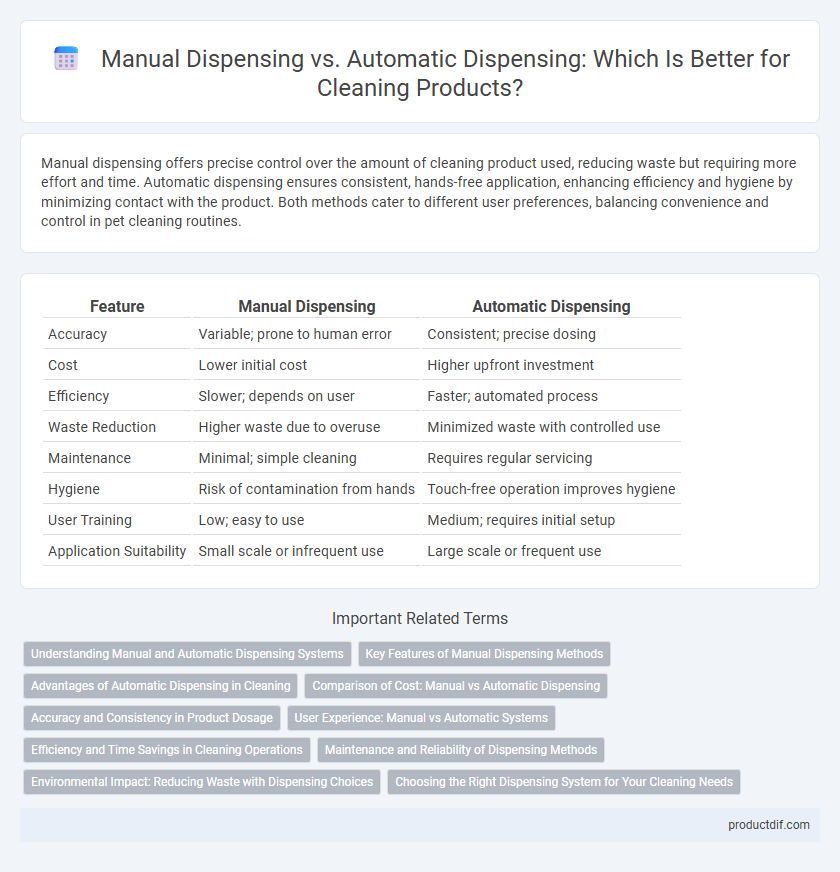

Table of Comparison

| Feature | Manual Dispensing | Automatic Dispensing |

|---|---|---|

| Accuracy | Variable; prone to human error | Consistent; precise dosing |

| Cost | Lower initial cost | Higher upfront investment |

| Efficiency | Slower; depends on user | Faster; automated process |

| Waste Reduction | Higher waste due to overuse | Minimized waste with controlled use |

| Maintenance | Minimal; simple cleaning | Requires regular servicing |

| Hygiene | Risk of contamination from hands | Touch-free operation improves hygiene |

| User Training | Low; easy to use | Medium; requires initial setup |

| Application Suitability | Small scale or infrequent use | Large scale or frequent use |

Understanding Manual and Automatic Dispensing Systems

Manual dispensing systems require users to operate pumps or valves, allowing precise control over the amount of cleaning product used, but may lead to inconsistent dosing and increased waste. Automatic dispensing systems use sensors and timers to deliver accurate and consistent quantities, reducing human error and improving efficiency in high-usage environments. Understanding these systems involves evaluating factors such as application volume, cost, and desired control level to optimize cleaning product usage and minimize environmental impact.

Key Features of Manual Dispensing Methods

Manual dispensing methods in cleaning products offer precise control over product quantity, minimizing waste through user-regulated amounts. These methods often require no power source, making them versatile for various environments and ensuring reliability during power outages. Designed for ease of use, manual dispensers typically feature intuitive mechanisms like pumps or squeezable bottles, enhancing user efficiency and reducing contamination risk.

Advantages of Automatic Dispensing in Cleaning

Automatic dispensing systems in cleaning products ensure precise and consistent doses, reducing waste and saving costs. These systems enhance hygiene by minimizing contact and cross-contamination risks, improving overall safety in cleaning environments. Furthermore, automatic dispensers streamline workflow efficiency, allowing staff to focus on more critical tasks without frequent manual refill interruptions.

Comparison of Cost: Manual vs Automatic Dispensing

Manual dispensing cleaning products typically incur lower upfront costs due to simpler equipment and minimal maintenance requirements. Automatic dispensing systems involve higher initial investment but reduce waste and improve accuracy, leading to long-term cost savings. Over time, automatic dispensers often prove more cost-effective by optimizing product usage and minimizing operator error expenses.

Accuracy and Consistency in Product Dosage

Manual dispensing often results in varied product dosage due to human error, affecting cleaning effectiveness and increasing waste. Automatic dispensing systems ensure precise, consistent measurements by using calibrated pumps or sensors, optimizing cleaning performance and reducing costs. Consistent dosage minimizes chemical overuse and environmental impact while maintaining hygiene standards.

User Experience: Manual vs Automatic Systems

Manual dispensing systems require users to physically measure and pour cleaning products, which can lead to inconsistent dosing and increased waste. Automatic dispensing systems improve user experience by delivering precise, consistent amounts of cleaner, reducing mess and saving time. These systems also minimize contact with chemicals, enhancing safety and convenience for the user.

Efficiency and Time Savings in Cleaning Operations

Manual dispensing requires more time and increases the risk of inconsistent chemical use, resulting in reduced cleaning efficiency and potential waste. Automatic dispensing systems ensure precise, controlled solutions every time, significantly accelerating cleaning operations and minimizing product overuse. Utilizing automatic dispensers enhances overall workforce productivity by allowing staff to focus on other tasks while maintaining optimal chemical application.

Maintenance and Reliability of Dispensing Methods

Manual dispensing systems require regular cleaning and calibration to maintain accuracy and prevent clogging, increasing maintenance efforts and downtime. Automatic dispensing units feature self-cleaning mechanisms and precision controls, which significantly improve reliability and reduce manual intervention. The durability of automatic dispensers often results in a longer service life and consistent dosing performance compared to manual methods.

Environmental Impact: Reducing Waste with Dispensing Choices

Manual dispensing often leads to inconsistent product use, causing excess waste and higher environmental impact due to over-dispensing. Automatic dispensing systems provide precise amounts, minimizing chemical runoff and packaging waste by ensuring each use delivers only what is needed. Choosing automatic dispensers supports sustainability goals by reducing resource consumption and lowering the carbon footprint associated with cleaning product usage.

Choosing the Right Dispensing System for Your Cleaning Needs

Manual dispensing systems offer precise control over product usage, making them ideal for smaller spaces and tasks requiring varied amounts of cleaning solutions. Automatic dispensing systems provide consistent, measured doses that reduce waste and improve hygiene by minimizing contact, suitable for high-traffic or large-scale cleaning environments. Selecting the right dispensing system depends on factors like usage frequency, facility size, and the need for accuracy versus convenience.

Manual dispensing vs Automatic dispensing Infographic

productdif.com

productdif.com