Microfiltration preserves the fresh flavor and nutritional value of beverages by filtering out microorganisms without heat, unlike pasteurization which uses high temperatures that can alter taste and reduce nutrient content. This cold process extends shelf life while maintaining clarity and natural characteristics, making it ideal for delicate drinks such as fruit juices and dairy alternatives. Conversely, pasteurization is highly effective at eliminating pathogens but may compromise sensory qualities and requires energy-intensive heating equipment.

Table of Comparison

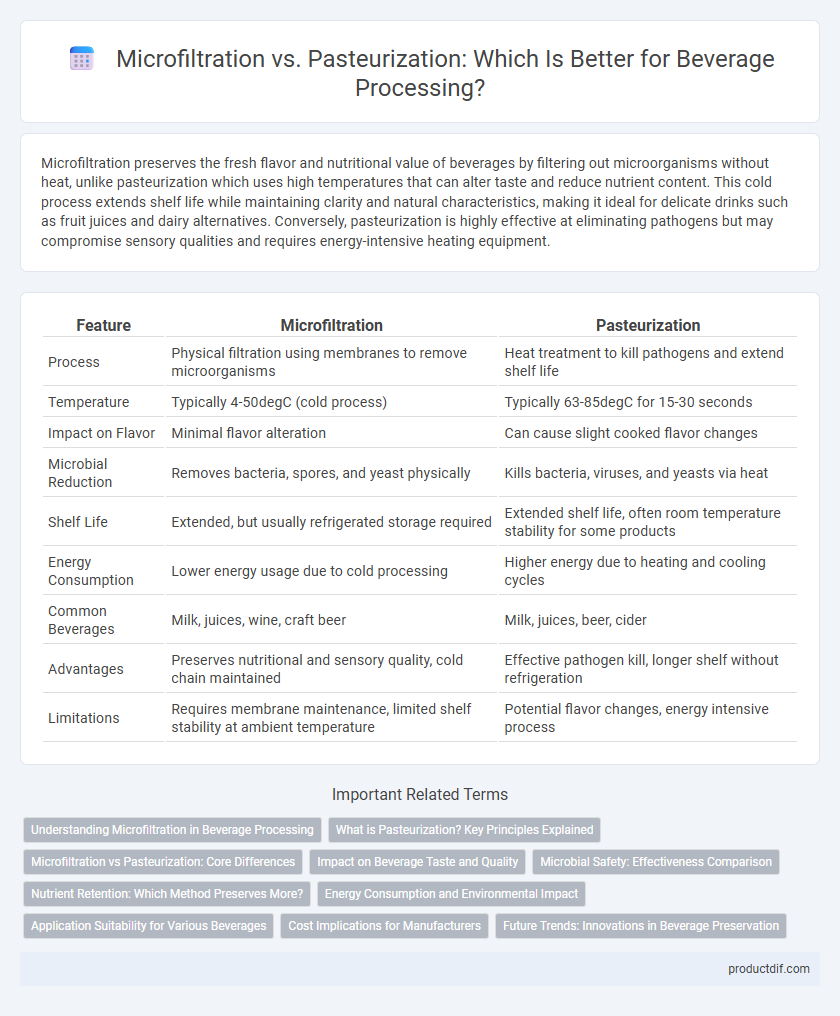

| Feature | Microfiltration | Pasteurization |

|---|---|---|

| Process | Physical filtration using membranes to remove microorganisms | Heat treatment to kill pathogens and extend shelf life |

| Temperature | Typically 4-50degC (cold process) | Typically 63-85degC for 15-30 seconds |

| Impact on Flavor | Minimal flavor alteration | Can cause slight cooked flavor changes |

| Microbial Reduction | Removes bacteria, spores, and yeast physically | Kills bacteria, viruses, and yeasts via heat |

| Shelf Life | Extended, but usually refrigerated storage required | Extended shelf life, often room temperature stability for some products |

| Energy Consumption | Lower energy usage due to cold processing | Higher energy due to heating and cooling cycles |

| Common Beverages | Milk, juices, wine, craft beer | Milk, juices, beer, cider |

| Advantages | Preserves nutritional and sensory quality, cold chain maintained | Effective pathogen kill, longer shelf without refrigeration |

| Limitations | Requires membrane maintenance, limited shelf stability at ambient temperature | Potential flavor changes, energy intensive process |

Understanding Microfiltration in Beverage Processing

Microfiltration in beverage processing uses membranes with pore sizes typically between 0.1 to 10 micrometers to remove microorganisms and suspended solids without heat, preserving flavor and nutritional quality. This cold filtration method enhances shelf life and maintains sensory attributes by eliminating bacteria and yeast while retaining vitamins and antioxidants. Compared to pasteurization, microfiltration offers a non-thermal alternative that reduces thermal degradation and energy consumption in beverage production.

What is Pasteurization? Key Principles Explained

Pasteurization is a heat treatment process that kills harmful microorganisms in beverages by heating the liquid to a specific temperature for a set period, typically 60-85degC for 15-30 seconds. This method preserves flavor and nutritional value while extending shelf life by reducing microbial load. Key principles involve carefully controlled temperature and time parameters to ensure safety without compromising product quality.

Microfiltration vs Pasteurization: Core Differences

Microfiltration uses a physical barrier to remove microorganisms and particles from beverages at low temperatures, preserving flavor and nutrients better than pasteurization. Pasteurization relies on heat treatment to kill pathogens, which can slightly alter taste and reduce some nutritional content. The core difference lies in microfiltration's gentle filtration process versus pasteurization's thermal destruction of microbes.

Impact on Beverage Taste and Quality

Microfiltration preserves the fresh flavor and natural aroma of beverages by gently removing microorganisms without heat, maintaining higher sensory quality compared to pasteurization. Pasteurization, involving thermal treatment, can alter taste profiles by causing slight cooked or caramelized notes and degrading heat-sensitive nutrients and volatile compounds. Choosing microfiltration enhances clarity and shelf-life while retaining the original beverage character favored in premium juice and dairy products.

Microbial Safety: Effectiveness Comparison

Microfiltration effectively removes bacteria and yeast by physically filtering out microorganisms larger than 0.1 to 0.2 microns, ensuring high microbial safety without heat exposure. Pasteurization uses thermal treatment to inactivate pathogens and spoilage microbes, achieving microbial safety but potentially altering beverage flavor and nutritional content. Studies show microfiltration maintains microbial safety levels comparable to pasteurization while preserving sensory and nutritional qualities in beverages.

Nutrient Retention: Which Method Preserves More?

Microfiltration preserves more nutrients in beverages compared to pasteurization by using a physical barrier to remove microorganisms without applying heat, thus maintaining heat-sensitive vitamins like vitamin C and enzymes. Pasteurization, involving high temperatures, can degrade sensitive nutrients and alter flavor profiles despite its effectiveness in microbial reduction. Studies show microfiltration retains higher levels of antioxidants and bioactive compounds, making it preferable for nutrient-rich beverage processing.

Energy Consumption and Environmental Impact

Microfiltration in beverage processing consumes significantly less energy than traditional pasteurization, reducing carbon emissions by minimizing heat usage. This membrane-based technology operates at lower temperatures, preserving product quality while decreasing the environmental footprint associated with high energy demand. Energy-efficient microfiltration offers a sustainable alternative that aligns with eco-friendly production standards in the beverage industry.

Application Suitability for Various Beverages

Microfiltration is ideal for delicate beverages such as fruit juices and dairy products, as it preserves natural flavors and nutrients by gently removing microbes without heat. Pasteurization suits beverages like milk and beer where heat treatment ensures microbial safety and extends shelf life through enzyme inactivation. Selecting microfiltration or pasteurization depends on the beverage's heat sensitivity, desired shelf stability, and flavor retention requirements.

Cost Implications for Manufacturers

Microfiltration offers a lower operational cost compared to pasteurization due to reduced energy consumption and minimal equipment maintenance requirements in beverage production. While pasteurization demands significant investment in heat exchangers and continuous energy input, microfiltration systems utilize membrane technology that extends filter lifespan and decreases downtime expenses. Manufacturers benefit from microfiltration's scalability and efficiency, which can lead to overall cost savings in large-scale beverage processing operations.

Future Trends: Innovations in Beverage Preservation

Emerging innovations in beverage preservation emphasize microfiltration as a promising alternative to traditional pasteurization, leveraging membrane technology to retain flavor and nutrients while extending shelf life. Advanced microfiltration techniques enable precise removal of microorganisms without thermal degradation, meeting consumer demand for fresh, minimally processed beverages. Future trends include integration of nanomaterials and automation in filtration systems to enhance efficiency and sustainability in beverage production.

Microfiltration vs Pasteurization Infographic

productdif.com

productdif.com