Inverter motors in appliances offer precise speed control and energy efficiency by adjusting power based on demand, reducing electricity consumption compared to standard motors that run at fixed speeds. The advanced technology in inverter motors minimizes noise and wear, enhancing appliance durability and performance. Standard motors, while typically more affordable, lack the adaptive features of inverter motors, resulting in higher energy use and less operational finesse.

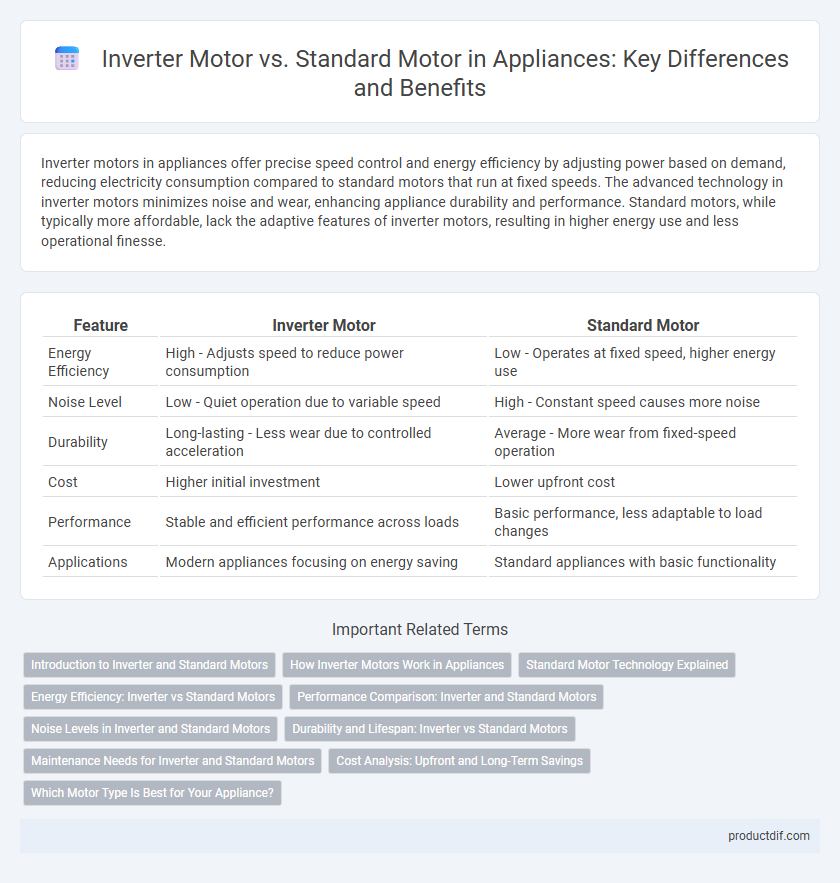

Table of Comparison

| Feature | Inverter Motor | Standard Motor |

|---|---|---|

| Energy Efficiency | High - Adjusts speed to reduce power consumption | Low - Operates at fixed speed, higher energy use |

| Noise Level | Low - Quiet operation due to variable speed | High - Constant speed causes more noise |

| Durability | Long-lasting - Less wear due to controlled acceleration | Average - More wear from fixed-speed operation |

| Cost | Higher initial investment | Lower upfront cost |

| Performance | Stable and efficient performance across loads | Basic performance, less adaptable to load changes |

| Applications | Modern appliances focusing on energy saving | Standard appliances with basic functionality |

Introduction to Inverter and Standard Motors

Inverter motors use variable frequency drives to control motor speed and torque, resulting in enhanced energy efficiency and precise performance in appliances such as refrigerators and air conditioners. Standard motors operate at a fixed speed, driven directly by the power supply frequency, which can lead to higher energy consumption and less adaptability. The integration of inverter technology allows appliances to optimize power usage, reduce wear and tear, and maintain consistent functionality under varying load conditions.

How Inverter Motors Work in Appliances

Inverter motors in appliances adjust their speed and power by varying the frequency of the electrical supply, enabling precise control and enhanced energy efficiency. Unlike standard motors that operate at fixed speeds, inverter motors selectively modulate their operation to match real-time appliance demands, reducing energy consumption and wear. This technology improves performance in devices like refrigerators, washing machines, and air conditioners by providing quieter operation and prolonged motor lifespan.

Standard Motor Technology Explained

Standard motor technology in appliances relies on fixed-speed operation using brushes and commutators to transfer current, resulting in consistent but less energy-efficient performance compared to inverter motors. These motors typically run at a constant speed, leading to higher power consumption and greater wear over time. Their straightforward design ensures lower initial costs and simpler maintenance but lacks the variable speed control that enhances efficiency and longevity in inverter motors.

Energy Efficiency: Inverter vs Standard Motors

Inverter motors optimize energy consumption by adjusting speed based on load, resulting in up to 30% more energy efficiency compared to standard motors that operate at constant speed. The variable frequency drive in inverter motors reduces electricity usage and minimizes wear and tear, extending appliance lifespan. Standard motors tend to consume more power continuously, making inverter motors the preferred choice for eco-friendly and cost-effective appliance operation.

Performance Comparison: Inverter and Standard Motors

Inverter motors deliver superior performance by adjusting speed and torque according to load demands, resulting in enhanced energy efficiency and quieter operation compared to standard motors. Standard motors operate at a fixed speed, leading to higher energy consumption and increased wear during variable load conditions. The adaptive technology in inverter motors provides smoother acceleration and precise control, significantly improving the lifespan and reliability of appliances.

Noise Levels in Inverter and Standard Motors

Inverter motors operate at variable speeds, significantly reducing noise levels compared to standard motors that run at fixed speeds and produce consistent, higher-pitched sounds. The noise reduction in inverter motors stems from smoother acceleration and deceleration processes, minimizing vibrations and mechanical stress. Standard motors typically generate louder operational noise due to constant full-speed rotation and abrupt starts and stops.

Durability and Lifespan: Inverter vs Standard Motors

Inverter motors offer enhanced durability and longer lifespan compared to standard motors due to their ability to operate at variable speeds, reducing wear and tear on components. The precise speed control in inverter motors minimizes mechanical stress and overheating, which commonly shortens the lifespan of standard motors running at fixed speeds. Appliances equipped with inverter motors often require fewer repairs and maintain efficiency over extended periods, making them a more reliable and cost-effective choice for long-term use.

Maintenance Needs for Inverter and Standard Motors

Inverter motors require less maintenance compared to standard motors due to their advanced design that reduces wear and tear by operating at variable speeds. Standard motors often demand frequent servicing and parts replacement because they run at constant speeds, leading to increased mechanical stress and heat buildup. The energy-efficient operation of inverter motors also minimizes motor overheating, extending the lifespan and reducing the frequency of maintenance intervals.

Cost Analysis: Upfront and Long-Term Savings

Inverter motors typically have a higher upfront cost compared to standard motors due to advanced technology and improved efficiency. Over the long term, inverter motors deliver significant energy savings and reduced maintenance expenses, resulting in lower total cost of ownership. Standard motors may offer lower initial investment but often incur higher operational costs, making inverter motors a more cost-effective choice for energy-conscious consumers.

Which Motor Type Is Best for Your Appliance?

Inverter motors offer superior energy efficiency, quieter operation, and longer lifespan compared to standard motors, making them ideal for appliances that require variable speed and consistent performance. Standard motors are more cost-effective upfront but consume more power and generate more noise, suitable for basic, fixed-speed applications. Choosing the best motor for your appliance depends on your priorities for energy savings, noise levels, and budget.

Inverter Motor vs Standard Motor Infographic

productdif.com

productdif.com