Inverter compressors adjust their speed to match cooling demands, resulting in enhanced energy efficiency and quieter operation compared to reciprocating compressors, which operate at a fixed speed with a start-stop cycle. The variable speed feature of inverter compressors reduces wear and tear, extends appliance lifespan, and maintains a more consistent temperature. Reciprocating compressors typically have a simpler design and lower upfront cost but may lead to higher energy consumption and increased noise levels over time.

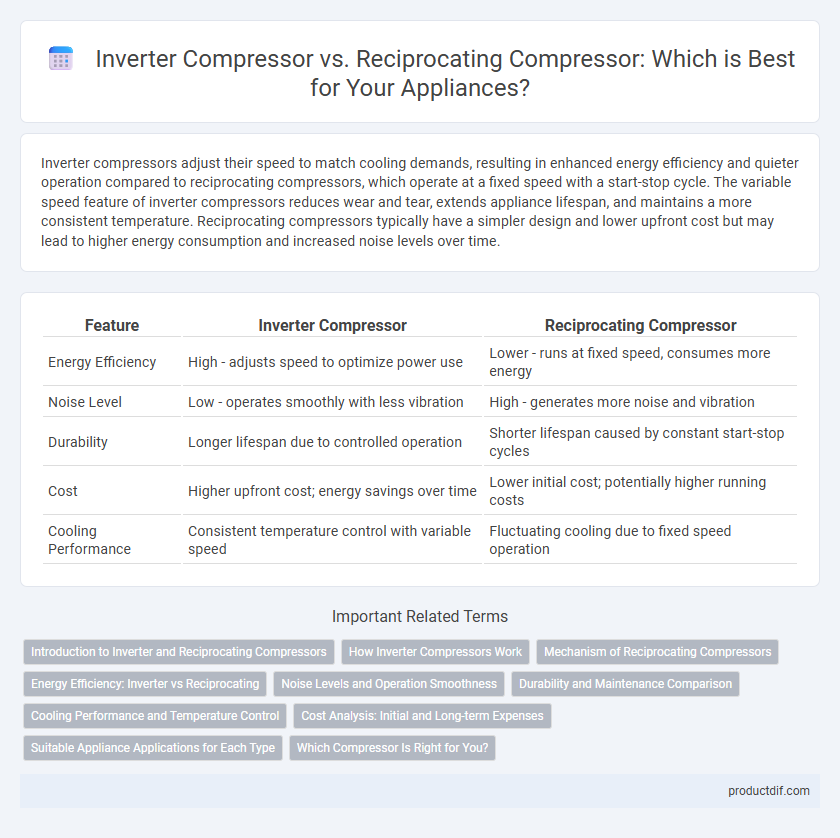

Table of Comparison

| Feature | Inverter Compressor | Reciprocating Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to optimize power use | Lower - runs at fixed speed, consumes more energy |

| Noise Level | Low - operates smoothly with less vibration | High - generates more noise and vibration |

| Durability | Longer lifespan due to controlled operation | Shorter lifespan caused by constant start-stop cycles |

| Cost | Higher upfront cost; energy savings over time | Lower initial cost; potentially higher running costs |

| Cooling Performance | Consistent temperature control with variable speed | Fluctuating cooling due to fixed speed operation |

Introduction to Inverter and Reciprocating Compressors

Inverter compressors regulate motor speed to optimize energy efficiency and temperature control, widely used in modern refrigerators and air conditioners. Reciprocating compressors operate with a piston mechanism that compresses refrigerant in fixed steps, commonly found in traditional HVAC and refrigeration systems. The inverter technology offers variable capacity, while reciprocating compressors run at a constant speed, impacting performance and energy consumption.

How Inverter Compressors Work

Inverter compressors operate by continuously adjusting their motor speed to regulate cooling output, enhancing energy efficiency compared to traditional reciprocating compressors that cycle on and off. This variable speed operation reduces power consumption and minimizes temperature fluctuations, optimizing appliance performance. Advanced microprocessor controls enable real-time adaptation to cooling demands, ensuring stable compressor operation and extending appliance lifespan.

Mechanism of Reciprocating Compressors

Reciprocating compressors operate using a piston within a cylinder that moves back and forth to compress refrigerant gas, creating high pressure in cycles. This mechanism relies on the linear motion of the piston to reduce volume and increase pressure, making it effective for variable load applications in appliances like refrigerators and air conditioners. The simplicity and robustness of the reciprocating design provide reliable performance, though it generally results in higher noise and vibration compared to inverter compressors.

Energy Efficiency: Inverter vs Reciprocating

Inverter compressors deliver superior energy efficiency by adjusting their speed to match cooling demands, reducing power consumption compared to the fixed-speed operation of reciprocating compressors. This adaptive technology minimizes energy waste during part-load conditions, leading to significant cost savings and lower environmental impact. Reciprocating compressors often consume more electricity due to their continuous start-stop cycles, which generate higher energy spikes.

Noise Levels and Operation Smoothness

Inverter compressors operate with variable speeds, significantly reducing noise levels and delivering smoother operation compared to traditional reciprocating compressors that run at a constant speed and produce more mechanical noise. The continuous modulation in inverter compressors minimizes vibrations and compressor wear while reciprocating types generate louder, abrupt sounds during start-stop cycles. These noise and smoothness advantages make inverter compressors ideal for appliances requiring quiet and efficient performance.

Durability and Maintenance Comparison

Inverter compressors offer enhanced durability due to their ability to operate at variable speeds, reducing wear and tear compared to the constant-speed reciprocating compressors. Maintenance requirements for inverter compressors are generally lower, as they experience less mechanical stress and produce less noise and vibration. Reciprocating compressors, while simpler and cheaper to repair, often require more frequent servicing to address issues from their repetitive start-stop cycles.

Cooling Performance and Temperature Control

Inverter compressors provide precise cooling performance by continuously adjusting motor speed to match cooling demand, resulting in faster temperature stabilization and improved energy efficiency compared to reciprocating compressors. Reciprocating compressors operate on an on-off cycle, causing temperature fluctuations and less consistent cooling, which can lead to increased wear and higher energy consumption. The advanced control system of inverter compressors enables superior temperature regulation, maintaining optimal indoor comfort with reduced noise and power usage.

Cost Analysis: Initial and Long-term Expenses

Inverter compressors typically have a higher initial cost compared to reciprocating compressors due to advanced technology and energy-efficient design. Over time, inverter compressors offer significant savings in electricity bills, reducing long-term operational expenses. Reciprocating compressors may incur lower upfront costs but often lead to increased maintenance and higher energy consumption, raising total lifetime costs.

Suitable Appliance Applications for Each Type

Inverter compressors are ideal for modern appliances such as energy-efficient refrigerators and air conditioners, where precise temperature control and variable speed operation enhance energy savings and durability. Reciprocating compressors suit appliances requiring robust performance under fluctuating loads, such as traditional refrigerators and industrial air conditioning units, due to their reliability and lower initial cost. Selection depends on the appliance's demand for energy efficiency, noise levels, and variable cooling capacity.

Which Compressor Is Right for You?

Inverter compressors provide energy-efficient performance and quieter operation by adjusting speed to match cooling demand, making them ideal for modern appliances requiring precise temperature control and lower electricity bills. Reciprocating compressors deliver consistent, powerful performance at a lower upfront cost but tend to consume more energy and produce more noise, suitable for budget-conscious users or heavy-duty applications. Choosing the right compressor depends on your priorities: prioritize energy savings and quiet operation with an inverter compressor or opt for the durability and affordability of a reciprocating compressor.

Inverter Compressor vs Reciprocating Compressor Infographic

productdif.com

productdif.com