Compressor cooling systems use a refrigeration cycle to efficiently remove heat, making them ideal for larger appliances requiring powerful cooling. Thermoelectric cooling relies on the Peltier effect, offering quieter operation and compact size but is less energy-efficient and better suited for small appliances. Understanding these differences helps in selecting the right cooling method for specific appliance needs.

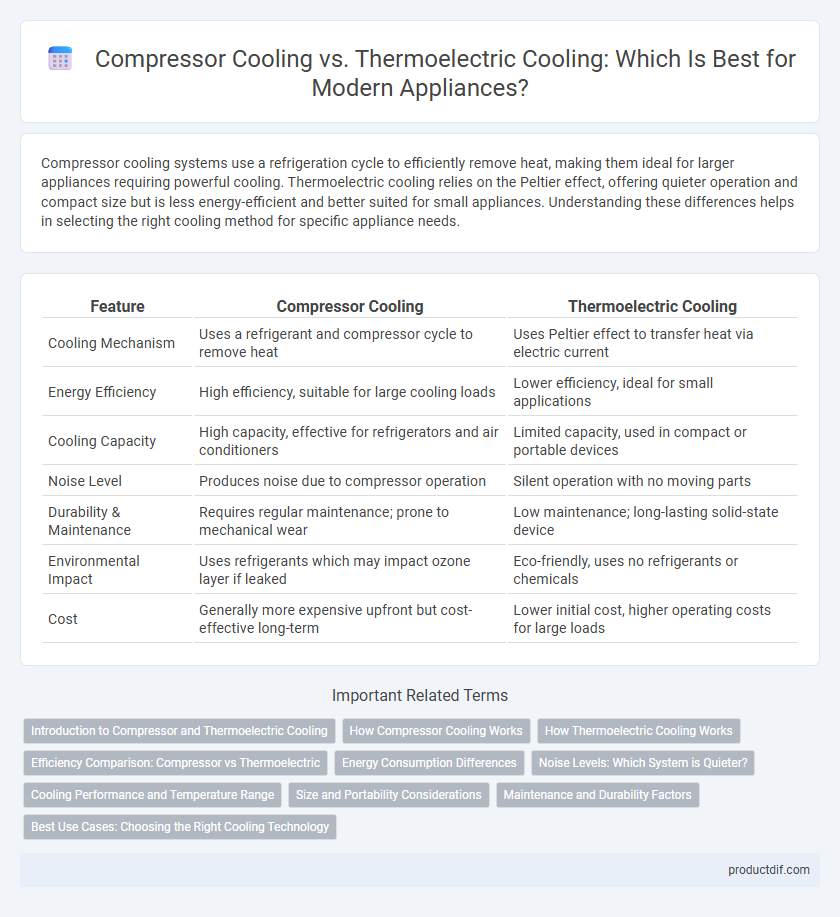

Table of Comparison

| Feature | Compressor Cooling | Thermoelectric Cooling |

|---|---|---|

| Cooling Mechanism | Uses a refrigerant and compressor cycle to remove heat | Uses Peltier effect to transfer heat via electric current |

| Energy Efficiency | High efficiency, suitable for large cooling loads | Lower efficiency, ideal for small applications |

| Cooling Capacity | High capacity, effective for refrigerators and air conditioners | Limited capacity, used in compact or portable devices |

| Noise Level | Produces noise due to compressor operation | Silent operation with no moving parts |

| Durability & Maintenance | Requires regular maintenance; prone to mechanical wear | Low maintenance; long-lasting solid-state device |

| Environmental Impact | Uses refrigerants which may impact ozone layer if leaked | Eco-friendly, uses no refrigerants or chemicals |

| Cost | Generally more expensive upfront but cost-effective long-term | Lower initial cost, higher operating costs for large loads |

Introduction to Compressor and Thermoelectric Cooling

Compressor cooling uses a refrigerant cycle driven by a motorized compressor to transfer heat efficiently, making it ideal for refrigerators and air conditioners with higher cooling capacity. Thermoelectric cooling relies on the Peltier effect, where an electric current creates a temperature difference across semiconductor materials, suitable for compact, portable coolers with no moving parts. Both methods serve distinct appliance needs, with compressor systems excelling in large-scale cooling and thermoelectric units favored for silent, maintenance-free operation.

How Compressor Cooling Works

Compressor cooling operates by compressing refrigerant gas, which raises its temperature and pressure before it is cooled in condenser coils and expanded to absorb heat from the appliance interior. This process efficiently regulates temperature by cycling refrigerant between high and low pressure states, removing heat from inside the system. Compressor cooling is widely used in refrigeration appliances due to its high cooling capacity and energy efficiency.

How Thermoelectric Cooling Works

Thermoelectric cooling operates through the Peltier effect, where applying an electric current between two different conductive materials creates a temperature difference, causing heat to move from one side to the other. Unlike compressor cooling, which relies on refrigerant gases and mechanical compression, thermoelectric modules are solid-state devices with no moving parts, resulting in quieter operation and increased reliability. These cooling systems are ideal for small appliances, such as mini refrigerators and wine coolers, offering precise temperature control and energy efficiency.

Efficiency Comparison: Compressor vs Thermoelectric

Compressor cooling systems achieve higher efficiency by using mechanical compression of refrigerants to rapidly remove heat, resulting in lower energy consumption for cooling larger volumes. Thermoelectric cooling relies on the Peltier effect, which is inherently less efficient due to its solid-state nature and generates more heat relative to the cooling output. In terms of energy efficiency and cooling capacity, compressors outperform thermoelectric coolers, particularly in appliances requiring sustained low temperatures.

Energy Consumption Differences

Compressor cooling systems typically consume more energy due to the mechanical compression cycle that requires significant power to maintain low temperatures. Thermoelectric cooling operates on the Peltier effect with no moving parts, resulting in lower energy consumption but less efficient cooling capacity compared to compressors. Energy efficiency ratings often show compressor-based appliances performing better in large-scale refrigeration, while thermoelectric coolers suit small, energy-conscious applications.

Noise Levels: Which System is Quieter?

Thermoelectric cooling systems generate significantly less noise than compressor cooling systems due to the absence of moving mechanical parts like compressors or fans. Compressor cooling relies on a motor-driven compressor that produces noticeable operational noise, often ranging from 40 to 60 decibels. For users prioritizing silent operation in appliances such as mini-fridges or wine coolers, thermoelectric models offer a quieter environment with noise levels typically below 30 decibels.

Cooling Performance and Temperature Range

Compressor cooling systems deliver superior cooling performance with rapid temperature reduction and a wider temperature range, typically between -25degC to 10degC, making them ideal for heavy-duty appliance cooling needs. Thermoelectric cooling offers quieter operation and precise temperature control but is limited to smaller temperature differences, generally maintaining 5degC to 25degC, best suited for compact or portable appliances. The choice between these cooling technologies hinges on the required temperature range and efficiency demands of the appliance.

Size and Portability Considerations

Compressor cooling systems are typically larger and heavier due to their mechanical components, making them less portable but highly efficient for larger appliances such as refrigerators. Thermoelectric cooling units are compact and lightweight, ideal for small, portable appliances like mini-fridges and beverage coolers where space and mobility are priorities. The size and portability differences make thermoelectric coolers suitable for personal use and travel, while compressor systems dominate in stationary, high-capacity cooling applications.

Maintenance and Durability Factors

Compressor cooling systems require regular maintenance including oil checks and refrigerant refills to ensure durability and optimal performance. Thermoelectric cooling units have fewer moving parts, resulting in lower maintenance needs and longer lifespan in environments with stable temperatures. Durability of compressor coolers can be compromised by mechanical wear, whereas thermoelectric coolers often resist wear but have limited cooling capacity impacting longevity under heavy duty use.

Best Use Cases: Choosing the Right Cooling Technology

Compressor cooling is ideal for high-capacity appliances such as refrigerators and air conditioners requiring rapid, consistent temperature reduction and efficient operation in diverse climates. Thermoelectric cooling suits small, portable devices like mini-fridges and wine coolers where quiet operation, low vibration, and compact size are critical. Selecting the right cooling technology depends on balancing factors like cooling power, energy efficiency, noise levels, and installation space.

Compressor Cooling vs Thermoelectric Cooling Infographic

productdif.com

productdif.com