Air-cooled appliances use fans to dissipate heat into the surrounding air, making them easier to install and maintain but sometimes less efficient in high-temperature environments. Water-cooled systems circulate water to absorb and remove heat more effectively, providing better cooling performance and reducing noise levels. Choosing between air-cooled and water-cooled depends on factors like installation space, ambient temperature, and cooling requirements for optimal appliance operation.

Table of Comparison

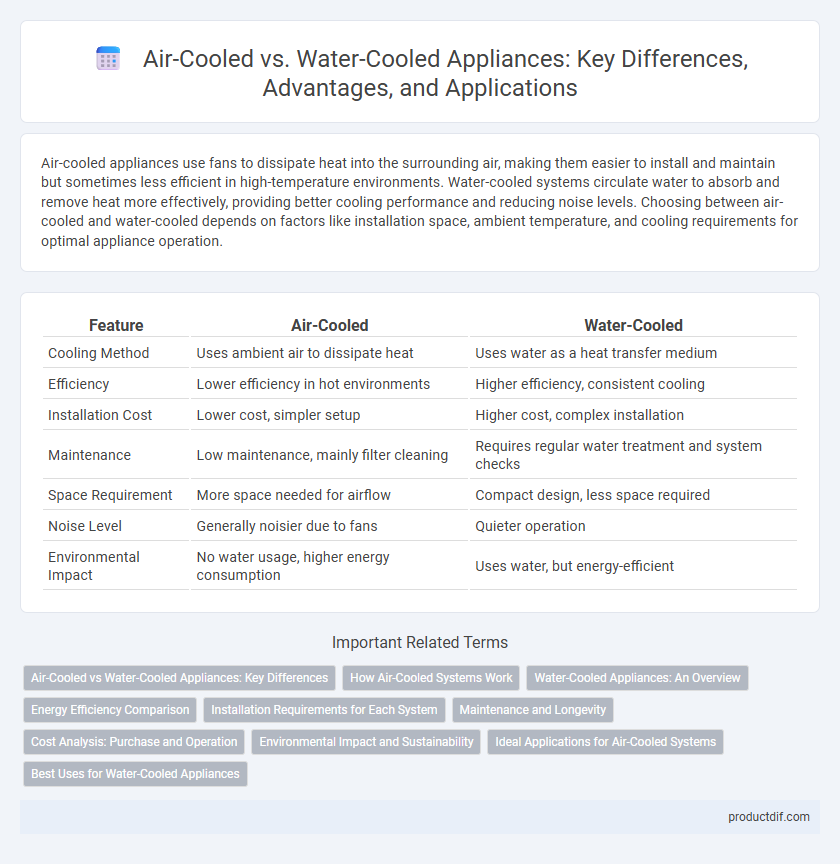

| Feature | Air-Cooled | Water-Cooled |

|---|---|---|

| Cooling Method | Uses ambient air to dissipate heat | Uses water as a heat transfer medium |

| Efficiency | Lower efficiency in hot environments | Higher efficiency, consistent cooling |

| Installation Cost | Lower cost, simpler setup | Higher cost, complex installation |

| Maintenance | Low maintenance, mainly filter cleaning | Requires regular water treatment and system checks |

| Space Requirement | More space needed for airflow | Compact design, less space required |

| Noise Level | Generally noisier due to fans | Quieter operation |

| Environmental Impact | No water usage, higher energy consumption | Uses water, but energy-efficient |

Air-Cooled vs Water-Cooled Appliances: Key Differences

Air-cooled appliances use ambient air to dissipate heat through fans or vents, making them simpler to install and maintain but less efficient in high-temperature environments. Water-cooled appliances rely on water to absorb and transfer heat, offering superior cooling performance and energy efficiency, especially in industrial or high-capacity settings. The choice between air-cooled and water-cooled appliances depends on factors such as climate, installation space, and cooling requirements.

How Air-Cooled Systems Work

Air-cooled systems operate by using ambient air to absorb and dissipate heat from components or appliances through heat exchangers or fins, relying on fans or natural airflow to enhance cooling efficiency. These systems circulate air over coils or radiators where heat transfers from the hot refrigerant or machinery to the air, which is then expelled outside the unit. Air-cooled appliances are commonly found in HVAC units, refrigerators, and electronics, offering simpler installation and lower maintenance compared to water-cooled counterparts.

Water-Cooled Appliances: An Overview

Water-cooled appliances utilize a continuous water flow to dissipate heat more efficiently, making them ideal for high-performance devices and industrial applications. These systems often require less energy to operate compared to air-cooled counterparts, contributing to improved overall efficiency and reduced operating costs. Proper maintenance and water quality management are critical to prevent scaling and corrosion, ensuring optimal appliance longevity and performance.

Energy Efficiency Comparison

Air-cooled systems typically consume more electricity as they rely on ambient air and fans for heat dissipation, leading to higher energy usage in warmer environments. Water-cooled appliances leverage water's superior thermal conductivity, resulting in more efficient heat transfer and reduced energy consumption, especially in large-scale or high-performance applications. Studies show water-cooled units can achieve energy savings of up to 30% compared to air-cooled counterparts, making them ideal for minimizing operational costs.

Installation Requirements for Each System

Air-cooled systems require ample outdoor space for condenser unit placement and sufficient airflow to prevent overheating, making installation simpler and often less costly in residential settings. Water-cooled systems demand a reliable water source, cooling towers, and complex plumbing infrastructure, leading to higher installation costs and space requirements typically suited for commercial or industrial applications. Proper site assessment is crucial for both systems to ensure compliance with building codes and to optimize operational efficiency.

Maintenance and Longevity

Air-cooled appliances typically require less complex maintenance due to their simpler design, but dust and debris buildup can impair efficiency and shorten lifespan if not regularly cleaned. Water-cooled systems necessitate routine checks for leaks, corrosion, and water quality to prevent scale buildup, which can significantly extend the appliance's longevity by maintaining optimal heat exchange performance. Proper maintenance of cooling components directly influences the durability and operational lifespan of both air-cooled and water-cooled appliances.

Cost Analysis: Purchase and Operation

Air-cooled appliances typically have lower initial purchase costs and simpler installation requirements compared to water-cooled systems, which demand additional infrastructure such as water pumps and cooling towers. Operational expenses for water-cooled systems may be higher due to the need for regular water treatment and maintenance, while air-cooled units often incur increased energy costs in warmer climates due to less efficient heat dissipation. Evaluating total cost of ownership, including energy consumption, maintenance, and water usage fees, is critical when choosing between air-cooled and water-cooled appliances.

Environmental Impact and Sustainability

Air-cooled appliances consume less water, reducing strain on local water resources and minimizing the risk of water contamination. Water-cooled systems typically achieve higher energy efficiency, lowering greenhouse gas emissions but may contribute to water scarcity and thermal pollution. Selecting air-cooled or water-cooled technology requires balancing energy savings with water conservation to enhance overall environmental sustainability.

Ideal Applications for Air-Cooled Systems

Air-cooled systems are ideal for residential and small commercial appliances where simplicity, lower initial cost, and ease of installation are priorities. These systems perform efficiently in environments with moderate ambient temperatures and limited access to water resources. Their maintenance requirements are minimal compared to water-cooled systems, making them suitable for HVAC units, refrigerators, and small-scale industrial machinery.

Best Uses for Water-Cooled Appliances

Water-cooled appliances excel in high-performance environments where efficient heat dissipation is critical, such as industrial refrigeration and large HVAC systems. These systems leverage water's superior thermal conductivity to maintain optimal operating temperatures, enhancing energy efficiency and prolonging equipment lifespan. Ideal applications include commercial buildings and data centers where consistent cooling is essential to prevent overheating and ensure reliable appliance operation.

Air-cooled vs Water-cooled Infographic

productdif.com

productdif.com