Internal Combustion Engine (ICE) vehicles rely on fossil fuels, producing significant greenhouse gas emissions, while Battery Electric Vehicles (BEVs) operate on electric power, offering zero tailpipe emissions and higher energy efficiency. BEVs require less maintenance due to fewer moving parts and avoid oil changes, contrasting with the complex engine systems and regular servicing needs of ICE vehicles. Advances in battery technology and expanding charging infrastructure are accelerating the adoption of BEVs, presenting a cleaner and more sustainable alternative to traditional ICE cars.

Table of Comparison

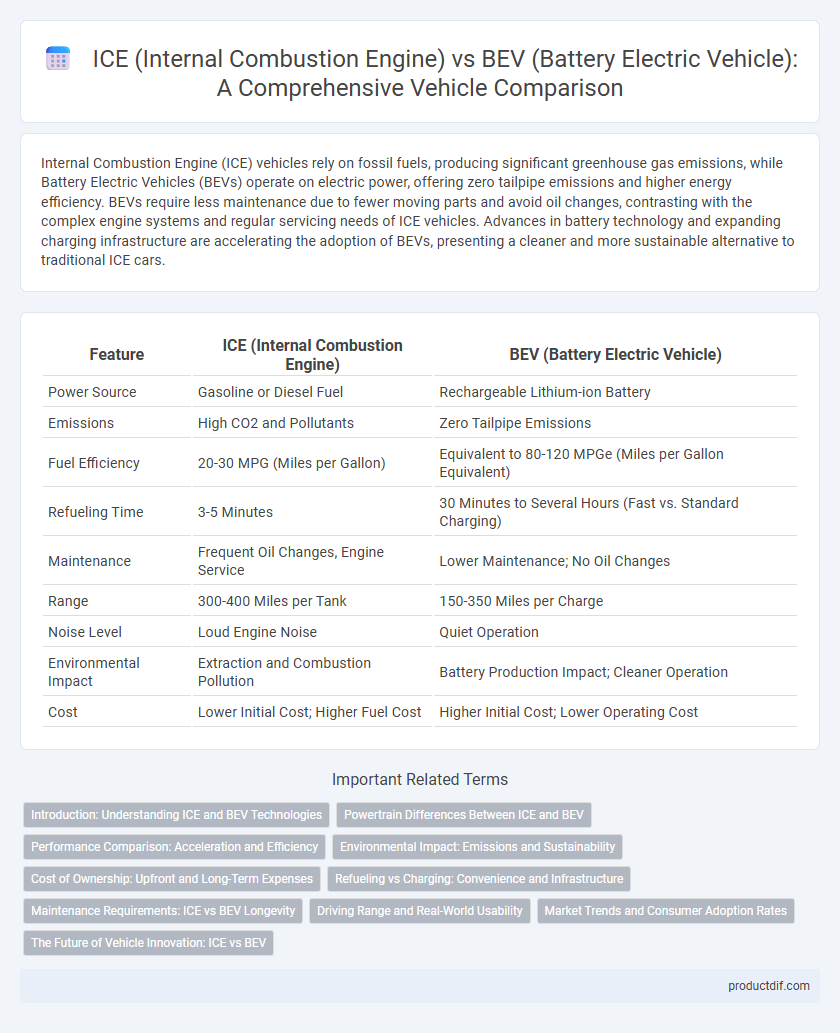

| Feature | ICE (Internal Combustion Engine) | BEV (Battery Electric Vehicle) |

|---|---|---|

| Power Source | Gasoline or Diesel Fuel | Rechargeable Lithium-ion Battery |

| Emissions | High CO2 and Pollutants | Zero Tailpipe Emissions |

| Fuel Efficiency | 20-30 MPG (Miles per Gallon) | Equivalent to 80-120 MPGe (Miles per Gallon Equivalent) |

| Refueling Time | 3-5 Minutes | 30 Minutes to Several Hours (Fast vs. Standard Charging) |

| Maintenance | Frequent Oil Changes, Engine Service | Lower Maintenance; No Oil Changes |

| Range | 300-400 Miles per Tank | 150-350 Miles per Charge |

| Noise Level | Loud Engine Noise | Quiet Operation |

| Environmental Impact | Extraction and Combustion Pollution | Battery Production Impact; Cleaner Operation |

| Cost | Lower Initial Cost; Higher Fuel Cost | Higher Initial Cost; Lower Operating Cost |

Introduction: Understanding ICE and BEV Technologies

Internal Combustion Engine (ICE) vehicles rely on burning fossil fuels like gasoline or diesel to generate mechanical power through controlled explosions within engine cylinders. Battery Electric Vehicles (BEVs) utilize rechargeable lithium-ion batteries to power electric motors, offering zero tailpipe emissions and higher energy efficiency. Understanding the fundamental technologies behind ICE and BEV highlights key differences in fuel sources, energy conversion, and environmental impact.

Powertrain Differences Between ICE and BEV

ICE vehicles rely on a multi-component powertrain featuring an internal combustion engine, transmission, fuel system, and exhaust system, which work together to convert fuel into mechanical energy. BEVs utilize a simpler powertrain architecture consisting primarily of electric motors, battery packs, power electronics, and a single-speed transmission, enabling instant torque and higher efficiency. The absence of components like fuel injectors and exhaust systems in BEVs reduces maintenance requirements and improves energy conversion compared to ICE powertrains.

Performance Comparison: Acceleration and Efficiency

Internal Combustion Engine (ICE) vehicles typically offer strong acceleration at higher speeds due to turbocharging and high horsepower outputs, but Battery Electric Vehicles (BEVs) excel in instant torque delivery, providing rapid 0-60 mph times often under 3 seconds in high-performance models. BEVs demonstrate higher energy efficiency, converting over 85% of electrical energy to wheel power compared to the 20-30% thermal efficiency of ICE engines, resulting in lower operating costs and reduced carbon emissions. Regenerative braking in BEVs further enhances energy efficiency, whereas ICE vehicles lose energy during deceleration and idling.

Environmental Impact: Emissions and Sustainability

Internal Combustion Engine (ICE) vehicles emit significant greenhouse gases, including CO2 and NOx, contributing to air pollution and climate change, whereas Battery Electric Vehicles (BEVs) produce zero tailpipe emissions, enhancing urban air quality. The lifecycle environmental impact of BEVs depends on battery production and electricity sources, with renewable energy reducing overall carbon footprint substantially. Sustainable practices in battery recycling and clean energy integration are critical to maximizing the environmental benefits of BEVs compared to ICE vehicles.

Cost of Ownership: Upfront and Long-Term Expenses

Battery Electric Vehicles (BEVs) typically have higher upfront costs due to expensive lithium-ion batteries, but lower long-term expenses including reduced fuel costs and minimal maintenance requirements compared to Internal Combustion Engine (ICE) vehicles. ICE vehicles incur ongoing costs for fuel, oil changes, and engine repairs, which often lead to higher lifetime ownership expenses despite lower initial purchase prices. Total cost of ownership analyses increasingly favor BEVs as battery prices decrease and incentives for electric vehicles promote overall savings.

Refueling vs Charging: Convenience and Infrastructure

Internal combustion engines (ICE) benefit from widespread refueling infrastructure, enabling rapid fuel top-ups at thousands of gas stations globally, often taking just a few minutes. Battery electric vehicles (BEVs) require charging that ranges from 30 minutes at fast-charging stations to several hours with home chargers, with public charging networks still expanding to meet growing demand. The convenience of refueling ICE vehicles continues to lead in speed and availability, whereas BEV charging infrastructure improvements focus on increasing accessibility and reducing downtime.

Maintenance Requirements: ICE vs BEV Longevity

Internal combustion engines require regular oil changes, spark plug replacements, and exhaust system maintenance, leading to higher long-term upkeep costs compared to battery electric vehicles. BEVs have fewer moving parts, eliminating the need for oil changes and reducing brake wear due to regenerative braking, thereby enhancing longevity and lowering maintenance demands. Battery health and thermal management remain critical for BEV longevity, with most manufacturers offering warranties around 8 years or 100,000 miles to address battery degradation.

Driving Range and Real-World Usability

Internal Combustion Engine (ICE) vehicles typically offer longer driving ranges, averaging 400-600 miles per full tank, and benefit from widespread refueling infrastructure enabling quick stops. Battery Electric Vehicles (BEVs) generally provide 200-350 miles per full charge, with range extending through advancements in battery technology and fast-charging networks increasing real-world usability. User driving patterns and access to charging facilities significantly influence the practicality of BEVs compared to ICE vehicles in daily use.

Market Trends and Consumer Adoption Rates

Market trends indicate a steady decline in Internal Combustion Engine (ICE) vehicle sales as Battery Electric Vehicles (BEVs) gain significant consumer adoption globally. BEVs benefit from increasing government incentives, expanded charging infrastructure, and heightened environmental awareness driving consumer preference. Data shows BEV market share has surged past 10% in key markets like Europe and China, signaling a transformative shift in automotive demand.

The Future of Vehicle Innovation: ICE vs BEV

Battery Electric Vehicles (BEVs) are rapidly surpassing Internal Combustion Engines (ICE) in efficiency, emissions reduction, and total cost of ownership. Advances in lithium-ion battery technology and expanding charging infrastructure are key drivers accelerating global BEV adoption. Despite ICE engines' long-standing dominance, stringent environmental regulations and consumer demand for sustainable mobility position BEVs as the primary focus of future vehicle innovation.

ICE (Internal Combustion Engine) vs BEV (Battery Electric Vehicle) Infographic

productdif.com

productdif.com