Tempered glass offers enhanced durability and resistance to thermal shock, making it ideal for everyday tableware use where impact resistance is crucial. Borosilicate glass, known for its superior thermal and chemical resistance, withstands extreme temperature changes without cracking, making it perfect for high-temperature applications and precise serving needs. Choosing between tempered and borosilicate glass depends on whether impact resistance or thermal stability is the priority for your tableware pet collection.

Table of Comparison

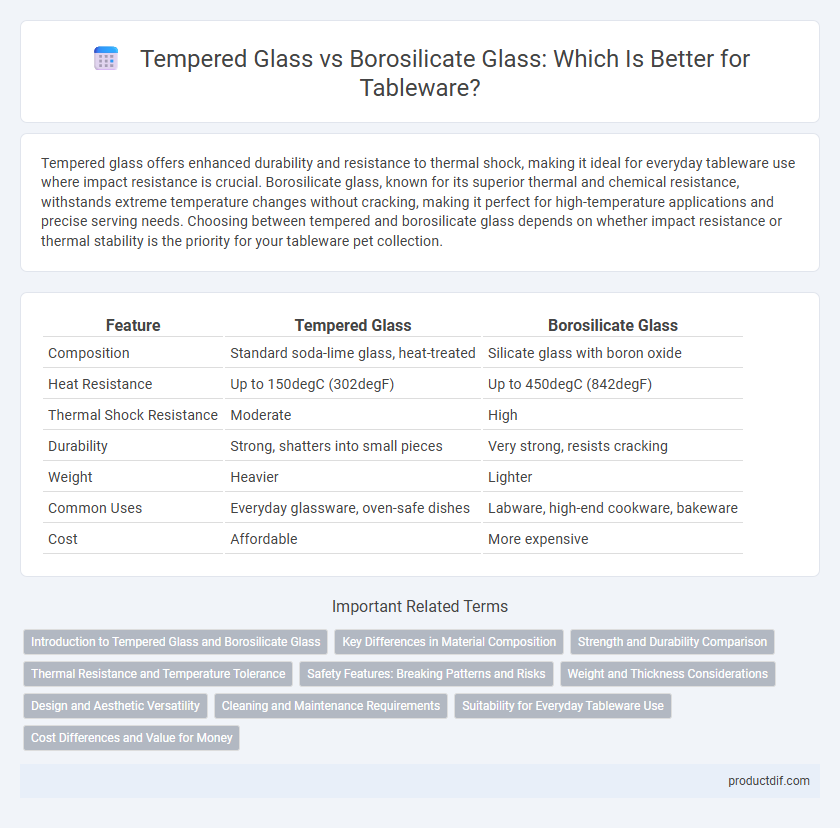

| Feature | Tempered Glass | Borosilicate Glass |

|---|---|---|

| Composition | Standard soda-lime glass, heat-treated | Silicate glass with boron oxide |

| Heat Resistance | Up to 150degC (302degF) | Up to 450degC (842degF) |

| Thermal Shock Resistance | Moderate | High |

| Durability | Strong, shatters into small pieces | Very strong, resists cracking |

| Weight | Heavier | Lighter |

| Common Uses | Everyday glassware, oven-safe dishes | Labware, high-end cookware, bakeware |

| Cost | Affordable | More expensive |

Introduction to Tempered Glass and Borosilicate Glass

Tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal glass, making it highly resistant to impact and thermal stress. Borosilicate glass is composed of silica and boron trioxide, known for its exceptional thermal shock resistance, durability, and chemical stability, often used in laboratory and kitchenware applications. Both materials offer distinct advantages in tableware, with tempered glass providing robust mechanical strength and borosilicate glass delivering superior heat resistance and longevity.

Key Differences in Material Composition

Tempered glass is made by rapidly cooling heated soda-lime glass, increasing its strength and resistance to thermal shock, while borosilicate glass consists of silica and boron trioxide, providing superior thermal resistance and chemical durability. The higher boron content in borosilicate glass results in a lower coefficient of thermal expansion compared to tempered glass, making it less prone to cracking under temperature changes. These material composition differences influence their applications, with tempered glass commonly used for everyday tableware and borosilicate glass favored for laboratory and high-heat culinary use.

Strength and Durability Comparison

Tempered glass exhibits high impact resistance due to a thermal tempering process that increases surface compression, making it less prone to breakage under sudden shocks. Borosilicate glass offers superior thermal durability and chemical resistance, with a low coefficient of thermal expansion that prevents cracking from rapid temperature changes. While tempered glass excels in mechanical strength, borosilicate glass provides enhanced longevity in both thermal and chemical stress environments, ideal for versatile tableware use.

Thermal Resistance and Temperature Tolerance

Tempered glass offers moderate thermal resistance with a temperature tolerance up to approximately 250degC (482degF), making it suitable for everyday tableware use such as serving dishes and drinkware. Borosilicate glass exhibits superior thermal resistance and can withstand rapid temperature changes and temperatures up to 450degC (842degF) without cracking, making it ideal for high-heat applications like baking and laboratory glassware. The enhanced durability and shock resistance of borosilicate glass provide greater safety and longevity in both domestic and professional culinary environments.

Safety Features: Breaking Patterns and Risks

Tempered glass used in tableware breaks into small, blunt pieces that reduce the risk of injury, making it a safer option in case of accidental impact. Borosilicate glass is more resistant to thermal shock but, when it breaks, it tends to shatter into larger, sharper fragments, increasing the potential for cuts. Understanding these breaking patterns is crucial for selecting tableware that balances durability and user safety.

Weight and Thickness Considerations

Tempered glass tableware is generally heavier and thicker due to its manufacturing process, which enhances its strength and durability. Borosilicate glass, known for its lightweight and thinner profile, offers superior thermal resistance, making it ideal for delicate designs and temperature variations. Choosing between tempered and borosilicate glass depends on the desired balance between sturdiness and ease of handling in everyday use.

Design and Aesthetic Versatility

Tempered glass offers sleek, modern design options with a smooth, polished finish that enhances minimalist table settings. Borosilicate glass provides superior clarity and resistance to thermal shock, allowing for intricate, artistic shapes that maintain elegance under various temperatures. Both materials support versatile aesthetics, but borosilicate glass excels in combining durability with creative design freedom.

Cleaning and Maintenance Requirements

Tempered glass tableware is easier to clean due to its smooth, non-porous surface that resists staining and does not absorb odors, requiring only mild detergent and warm water for maintenance. Borosilicate glass, known for its thermal resistance, demands gentle cleaning to avoid scratches, using non-abrasive sponges and avoiding harsh chemicals to preserve clarity and durability. Both materials offer dishwasher-safe options, but manual cleaning extends their lifespan and maintains the pristine appearance of tableware.

Suitability for Everyday Tableware Use

Tempered glass offers excellent durability and resistance to impact, making it highly suitable for everyday tableware that requires frequent handling and washing. Borosilicate glass provides superior thermal shock resistance, ideal for dishes subjected to rapid temperature changes such as hot to cold liquids. For daily use, tempered glass is preferred for its toughness and affordability, while borosilicate glass excels in environments requiring extreme temperature durability.

Cost Differences and Value for Money

Tempered glass tableware is generally more affordable due to its mass production and lower raw material costs, making it a budget-friendly option for everyday use. Borosilicate glass, while more expensive, offers superior thermal resistance and durability, providing greater long-term value for buyers who prioritize performance and longevity. The higher initial investment in borosilicate glass often results in reduced replacement expenses, enhancing overall cost-effectiveness.

Tempered glass vs Borosilicate glass Infographic

productdif.com

productdif.com