Plate warping occurs when a ceramic plate bends or distorts due to uneven heating or cooling, leading to an uneven surface that can affect stability and usability. Plate crazing refers to a network of fine cracks in the glaze caused by differences in the thermal expansion between the glaze and the clay body, which can weaken the plate and potentially harbor bacteria. Understanding the differences between warping and crazing is essential for maintaining the longevity and safety of tableware pets.

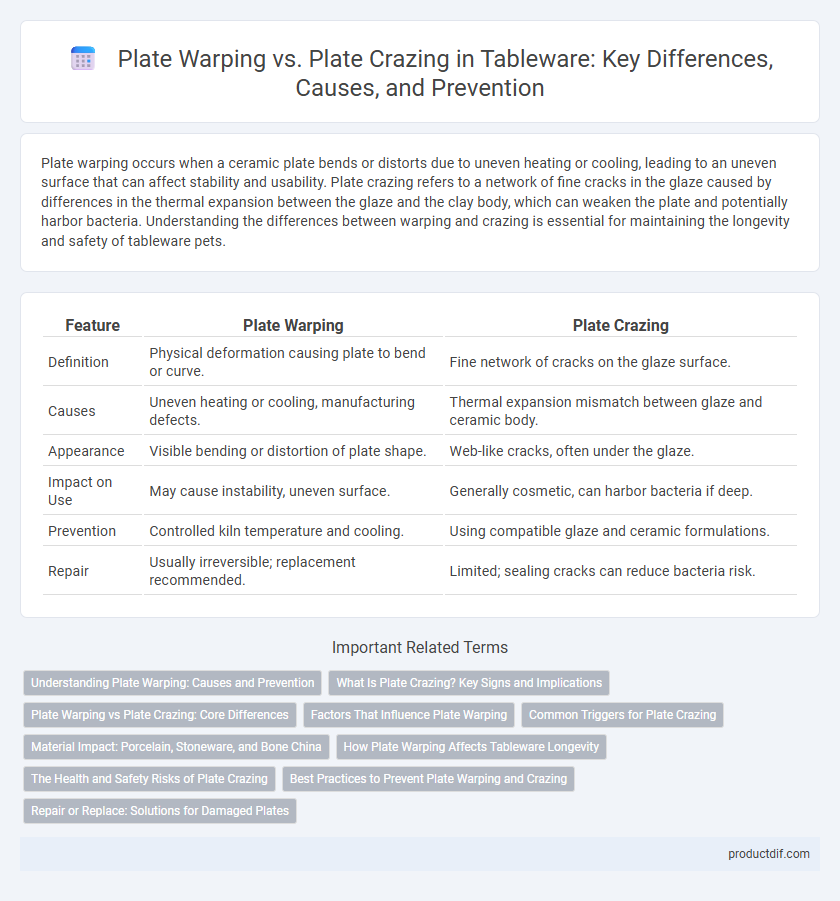

Table of Comparison

| Feature | Plate Warping | Plate Crazing |

|---|---|---|

| Definition | Physical deformation causing plate to bend or curve. | Fine network of cracks on the glaze surface. |

| Causes | Uneven heating or cooling, manufacturing defects. | Thermal expansion mismatch between glaze and ceramic body. |

| Appearance | Visible bending or distortion of plate shape. | Web-like cracks, often under the glaze. |

| Impact on Use | May cause instability, uneven surface. | Generally cosmetic, can harbor bacteria if deep. |

| Prevention | Controlled kiln temperature and cooling. | Using compatible glaze and ceramic formulations. |

| Repair | Usually irreversible; replacement recommended. | Limited; sealing cracks can reduce bacteria risk. |

Understanding Plate Warping: Causes and Prevention

Plate warping occurs when ceramic or porcelain plates deform due to uneven heating or cooling during firing, causing the surface to become uneven and compromising structural integrity. Common causes include rapid temperature changes, improper kiln settings, and residual stresses in the clay body. Preventing plate warping involves controlled heating and cooling cycles, use of well-formulated clay bodies, and ensuring even heat distribution in the kiln.

What Is Plate Crazing? Key Signs and Implications

Plate crazing refers to a network of fine cracks that appear on the glazed surface of ceramic plates due to microscopic expansion and contraction over time. Key signs include visible hairline fractures that do not penetrate the plate but alter its smooth texture and can harbor bacteria, affecting hygiene. While plate crazing rarely compromises structural integrity, it can indicate age-related wear and reduce the plate's aesthetic and resale value.

Plate Warping vs Plate Crazing: Core Differences

Plate warping refers to the physical distortion or bending of a plate's shape due to uneven heating or cooling, resulting in a visibly uneven surface. Plate crazing involves a network of fine cracks in the glaze caused by thermal expansion mismatches between the glaze and ceramic body, compromising the plate's aesthetic but not its structural integrity. The core difference lies in warping affecting the plate's form and stability, while crazing primarily impacts the surface appearance without altering the plate's shape.

Factors That Influence Plate Warping

Plate warping primarily results from uneven heating and cooling rates during manufacturing or use, causing the ceramic material to deform. The thickness and composition of the plate, as well as kiln temperature inconsistencies, significantly influence the likelihood of warping. Improper glazing that fails to accommodate thermal expansion differences also contributes to the development of warped plates.

Common Triggers for Plate Crazing

Plate crazing occurs when fine cracks develop on the glaze surface due to rapid temperature changes or prolonged exposure to moisture, commonly triggered by placing hot food on cold plates or dishwasher use. This shallow network of cracks weakens the glaze, allowing bacteria and stains to accumulate, posing hygiene concerns. Unlike plate warping, which alters the shape of the ceramic, crazing primarily affects the plate's surface integrity and visual appearance.

Material Impact: Porcelain, Stoneware, and Bone China

Porcelain, Stoneware, and Bone China each respond differently to plate warping and crazing due to their unique material compositions and firing processes. Porcelain, known for its high vitrification, resists warping but is prone to crazing if subjected to rapid temperature changes or improper glazing. Stoneware's dense structure offers excellent durability against warping, while Bone China's high translucency and calcium phosphate content make it less susceptible to crazing but sometimes vulnerable to warping under uneven heating.

How Plate Warping Affects Tableware Longevity

Plate warping in tableware compromises its structural integrity by causing uneven surfaces that can lead to instability and increased breakage risk during use. Unlike plate crazing, which primarily affects the glaze and aesthetic appearance, warping distorts the plate's shape, reducing its usability and overall lifespan. Prolonged exposure to heat fluctuations or improper storage accelerates warping, significantly shortening the longevity of ceramic and porcelain tableware collections.

The Health and Safety Risks of Plate Crazing

Plate crazing, characterized by fine cracks in the glaze, poses significant health and safety risks as it can harbor bacteria, making it difficult to sanitize properly. Unlike plate warping, which mainly affects the plate's shape and usability, crazing compromises the integrity of the surface, increasing the likelihood of contamination. Consuming food from crazed plates may lead to exposure to harmful microorganisms and potential foodborne illnesses.

Best Practices to Prevent Plate Warping and Crazing

To prevent plate warping, maintain moderate oven and dishwasher temperatures and avoid rapid temperature changes that stress the ceramic material. Minimize exposure to harsh detergents and avoid stacking plates too tightly to reduce surface tension, which helps prevent plate crazing. Using high-quality, well-fired ceramics with proper glazing techniques also enhances durability against both warping and crazing.

Repair or Replace: Solutions for Damaged Plates

Plate warping often results from uneven heat exposure and can sometimes be corrected by carefully reheating and reshaping, though replacement is generally recommended if the distortion affects stability. Plate crazing, characterized by fine cracks in the glaze, compromises durability and hygiene, making repair impractical and replacement the safer long-term solution. Selecting high-quality, oven-safe ceramic or porcelain plates minimizes the risk of warping and crazing, prolonging tableware lifespan.

Plate Warping vs Plate Crazing Infographic

productdif.com

productdif.com