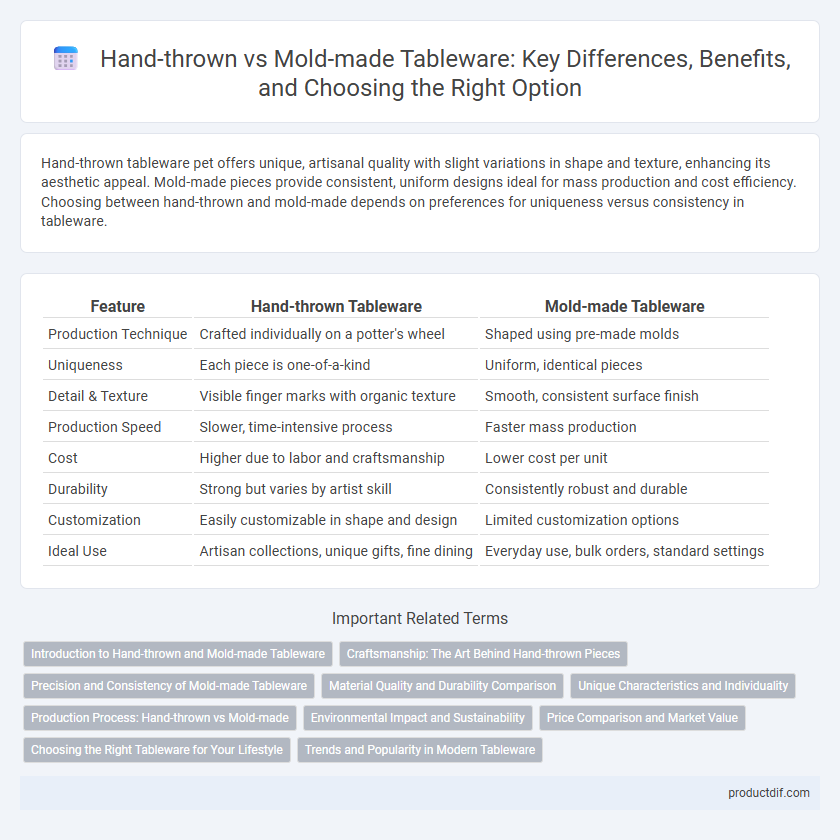

Hand-thrown tableware pet offers unique, artisanal quality with slight variations in shape and texture, enhancing its aesthetic appeal. Mold-made pieces provide consistent, uniform designs ideal for mass production and cost efficiency. Choosing between hand-thrown and mold-made depends on preferences for uniqueness versus consistency in tableware.

Table of Comparison

| Feature | Hand-thrown Tableware | Mold-made Tableware |

|---|---|---|

| Production Technique | Crafted individually on a potter's wheel | Shaped using pre-made molds |

| Uniqueness | Each piece is one-of-a-kind | Uniform, identical pieces |

| Detail & Texture | Visible finger marks with organic texture | Smooth, consistent surface finish |

| Production Speed | Slower, time-intensive process | Faster mass production |

| Cost | Higher due to labor and craftsmanship | Lower cost per unit |

| Durability | Strong but varies by artist skill | Consistently robust and durable |

| Customization | Easily customizable in shape and design | Limited customization options |

| Ideal Use | Artisan collections, unique gifts, fine dining | Everyday use, bulk orders, standard settings |

Introduction to Hand-thrown and Mold-made Tableware

Hand-thrown tableware is crafted by skilled artisans using a potter's wheel, resulting in unique, organic shapes with subtle variations in texture and form. Mold-made tableware is produced through a mechanized process that uses pre-designed molds, allowing for precise, uniform pieces ideal for mass production. Both methods offer distinct advantages in aesthetics and production scale, catering to different preferences and market demands.

Craftsmanship: The Art Behind Hand-thrown Pieces

Hand-thrown tableware exemplifies exquisite craftsmanship through the potter's intimate control over clay on the wheel, resulting in unique, one-of-a-kind shapes and textures. This artisanal technique emphasizes tactile skill and subtle variations that cannot be replicated by mold-made processes, enhancing the aesthetic and tactile appeal of each piece. Collectors and connoisseurs value hand-thrown pottery for its organic imperfections that reflect the creator's individual artistry and dedication.

Precision and Consistency of Mold-made Tableware

Mold-made tableware offers superior precision and consistency in shape and size compared to hand-thrown pieces, ensuring uniformity across large production batches. The use of industrial molds allows for exact replication of intricate designs and smooth finishes, reducing variability often seen in handcrafted items. This consistency is crucial for commercial settings where compatibility and stackability are essential.

Material Quality and Durability Comparison

Hand-thrown tableware, crafted from high-quality clay, often exhibits superior material density and unique glaze applications, resulting in enhanced durability and resistance to chipping. Mold-made pieces, produced from consistent clay mixtures and uniform firing processes, ensure standardized strength but may lack the distinct structural integrity found in hand-thrown items. The choice between the two impacts longevity and wear, with hand-thrown tableware typically favored for artisanal strength and mold-made for economic durability.

Unique Characteristics and Individuality

Hand-thrown tableware boasts unique characteristics with each piece displaying subtle variations in shape, texture, and glaze, reflecting the potter's individual touch and expertise. Mold-made tableware offers consistent uniformity with precise dimensions and patterns, ideal for mass production but lacking the distinct personality found in hand-crafted items. Collectors and enthusiasts often value hand-thrown pieces for their artistic individuality and tactile imperfections that cannot be replicated by molds.

Production Process: Hand-thrown vs Mold-made

Hand-thrown tableware is crafted by skillfully shaping clay on a potter's wheel, allowing artisans to create unique, one-of-a-kind pieces with subtle variations and organic textures. Mold-made tableware, in contrast, is produced through pressing or slip casting clay into pre-designed molds, enabling high-volume manufacturing with consistent shapes and dimensions. The hand-thrown process emphasizes craftsmanship and individuality, while mold-made production prioritizes efficiency and uniformity.

Environmental Impact and Sustainability

Hand-thrown tableware typically has a lower environmental impact due to its artisanal production methods, which consume less energy and generate minimal waste compared to mold-made pieces. Mold-made tableware often involves mass production with higher energy consumption and non-recyclable materials, contributing to larger carbon footprints and landfill waste. Choosing hand-thrown ceramics supports sustainable practices by promoting local craftsmanship and reducing reliance on industrial manufacturing processes.

Price Comparison and Market Value

Hand-thrown tableware commands a higher price due to its artisanal craftsmanship and uniqueness, often valued by collectors and connoisseurs seeking authenticity. Mold-made pieces are more affordable, benefiting from mass production efficiencies and consistency in design, appealing to budget-conscious consumers. Market value for hand-thrown ceramics typically appreciates over time, while mold-made items maintain stable, lower price points with less potential for resale growth.

Choosing the Right Tableware for Your Lifestyle

Hand-thrown tableware offers unique, artisanal qualities with variations in texture and design that suit individuals valuing craftsmanship and personalization. Mold-made tableware provides consistency, durability, and cost-effectiveness, ideal for busy households or large gatherings requiring uniform sets. Selecting the right tableware depends on lifestyle preferences, balancing aesthetics with practicality and maintenance needs.

Trends and Popularity in Modern Tableware

Hand-thrown tableware captures artisanal craftsmanship and unique, organic designs that appeal to consumers seeking authenticity and individuality. Mold-made tableware dominates mass production with consistent quality and variety, meeting the demand for affordable, standardized pieces in modern households and restaurants. Current trends highlight a growing appreciation for hybrid collections that combine hand-thrown aesthetics with the efficiency of mold-made techniques to balance artistry and accessibility.

Hand-thrown vs Mold-made Infographic

productdif.com

productdif.com