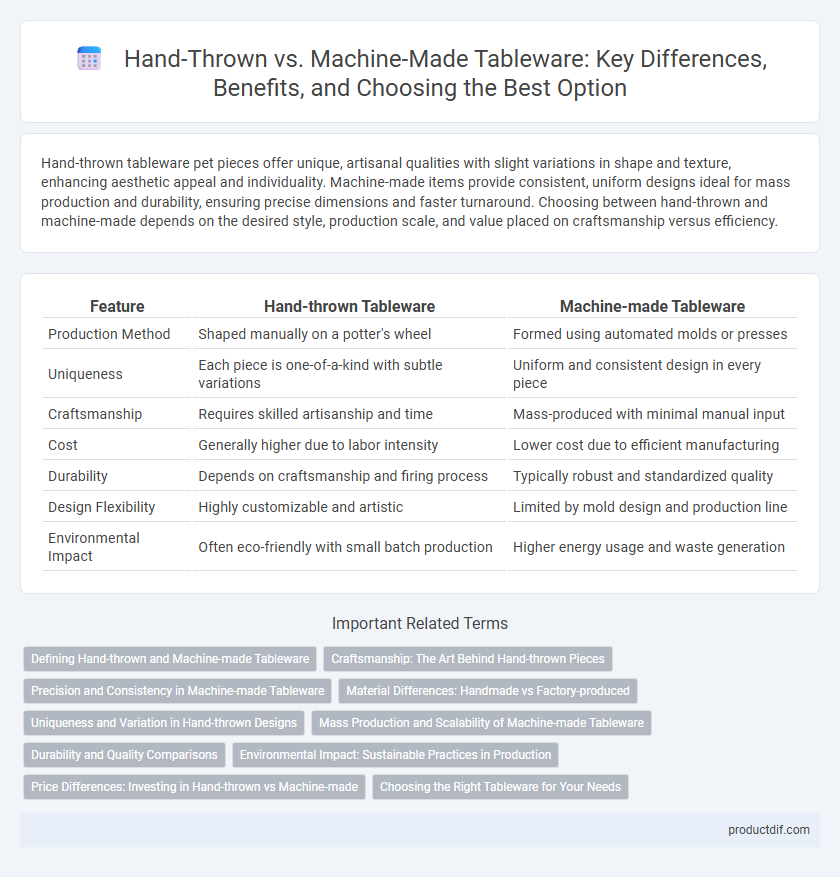

Hand-thrown tableware pet pieces offer unique, artisanal qualities with slight variations in shape and texture, enhancing aesthetic appeal and individuality. Machine-made items provide consistent, uniform designs ideal for mass production and durability, ensuring precise dimensions and faster turnaround. Choosing between hand-thrown and machine-made depends on the desired style, production scale, and value placed on craftsmanship versus efficiency.

Table of Comparison

| Feature | Hand-thrown Tableware | Machine-made Tableware |

|---|---|---|

| Production Method | Shaped manually on a potter's wheel | Formed using automated molds or presses |

| Uniqueness | Each piece is one-of-a-kind with subtle variations | Uniform and consistent design in every piece |

| Craftsmanship | Requires skilled artisanship and time | Mass-produced with minimal manual input |

| Cost | Generally higher due to labor intensity | Lower cost due to efficient manufacturing |

| Durability | Depends on craftsmanship and firing process | Typically robust and standardized quality |

| Design Flexibility | Highly customizable and artistic | Limited by mold design and production line |

| Environmental Impact | Often eco-friendly with small batch production | Higher energy usage and waste generation |

Defining Hand-thrown and Machine-made Tableware

Hand-thrown tableware is crafted by skilled artisans on a potter's wheel, allowing for unique, irregular shapes and individual artistic expression in each piece. Machine-made tableware is produced using automated molds and machinery, ensuring uniformity, precision, and high-volume output. The distinction lies in the level of manual craftsmanship versus industrial efficiency, influencing texture, design complexity, and production scale.

Craftsmanship: The Art Behind Hand-thrown Pieces

Hand-thrown tableware showcases the unique craftsmanship of skilled artisans, where each piece reflects individual creativity and subtle variations in shape, texture, and glaze. This manual process uses traditional pottery wheels, emphasizing precision and artistic expression, resulting in one-of-a-kind ceramics with distinctive character and tactile appeal. In contrast, machine-made tableware prioritizes uniformity and mass production, often lacking the artisanal touch inherent to hand-thrown creations.

Precision and Consistency in Machine-made Tableware

Machine-made tableware ensures superior precision and consistency through automated production processes that maintain uniform thickness, shape, and dimensions across each piece. This level of accuracy reduces the risk of defects and enhances durability, making machine-made items ideal for standardized dining settings. Precision tooling and quality control systems consistently deliver tableware with flawless finishes and exact specifications unattainable in hand-thrown alternatives.

Material Differences: Handmade vs Factory-produced

Hand-thrown tableware often uses natural clay varieties like stoneware or porcelain, allowing for unique textures and subtle material variations due to artisanal firing methods. Machine-made pieces typically utilize refined, homogenized clay blends designed for consistent strength and uniformity during mass production. The intrinsic material differences influence durability, surface finish, and the tactile experience between handmade and factory-produced tableware.

Uniqueness and Variation in Hand-thrown Designs

Hand-thrown tableware showcases unparalleled uniqueness, as each piece exhibits slight variations in shape, texture, and glaze resulting from the artisan's individual touch and wheel speed. This craftsmanship creates distinct imperfections and organic patterns that cannot be replicated by machine-made production, enhancing the aesthetic and tactile appeal. Collectors and chefs often value hand-thrown designs for their one-of-a-kind character and artisanal authenticity in dining experiences.

Mass Production and Scalability of Machine-made Tableware

Machine-made tableware enables mass production with consistent quality and rapid output, meeting high consumer demand efficiently. Automated processes increase scalability by reducing labor costs and minimizing production time compared to hand-thrown methods. This industrial approach supports large-scale distribution while maintaining uniformity across each piece.

Durability and Quality Comparisons

Hand-thrown tableware often exhibits superior durability and uniqueness due to the artisanal craftsmanship involved, resulting in thicker, more robust pottery with slight variations that enhance aesthetic value. Machine-made tableware offers consistent quality and uniformity, but may lack the structural strength and character found in hand-thrown pieces. Both types utilize different clay compositions and firing techniques that significantly impact their longevity and resistance to chipping or cracking under daily use.

Environmental Impact: Sustainable Practices in Production

Hand-thrown tableware typically has a lower environmental impact due to its artisanal production process, which uses less energy and generates minimal waste compared to machine-made methods. Machine-made tableware, while efficient for mass production, relies on heavy industrial equipment that consumes significant electricity and often involves synthetic materials and chemical glazes that can harm ecosystems. Sustainable practices in hand-thrown pottery include using locally sourced clay and natural glazes, promoting reduced carbon footprints and supporting eco-friendly production cycles within the ceramic industry.

Price Differences: Investing in Hand-thrown vs Machine-made

Hand-thrown tableware typically commands a higher price due to the skilled craftsmanship and time-intensive process involved in its creation, appealing to buyers seeking unique, artisanal pieces. Machine-made tableware offers a more budget-friendly option with consistent quality and mass production efficiency, making it ideal for everyday use or large-scale purchasing. The investment in hand-thrown pieces often reflects their exclusivity and artistic value, while machine-made items prioritize affordability and uniformity.

Choosing the Right Tableware for Your Needs

Hand-thrown tableware offers unique craftsmanship and subtle variations, making each piece one-of-a-kind and ideal for those valuing artisanal aesthetics. Machine-made tableware ensures consistent quality, uniformity, and often durability, suitable for bulk use or formal settings. Selecting the right tableware depends on balancing the desire for artistic individuality with practical needs like quantity, cost, and durability.

Hand-thrown vs Machine-made Infographic

productdif.com

productdif.com