Glaze firing transforms bisque-fired pottery by melting glaze into a glassy coating, enhancing durability and aesthetic appeal with vibrant colors and smooth textures. Bisque firing, the initial firing process, hardens the clay, making it porous and ready to absorb glaze without breaking during handling. Understanding the distinction between glaze firing and bisque firing is essential for creating durable, visually appealing tableware.

Table of Comparison

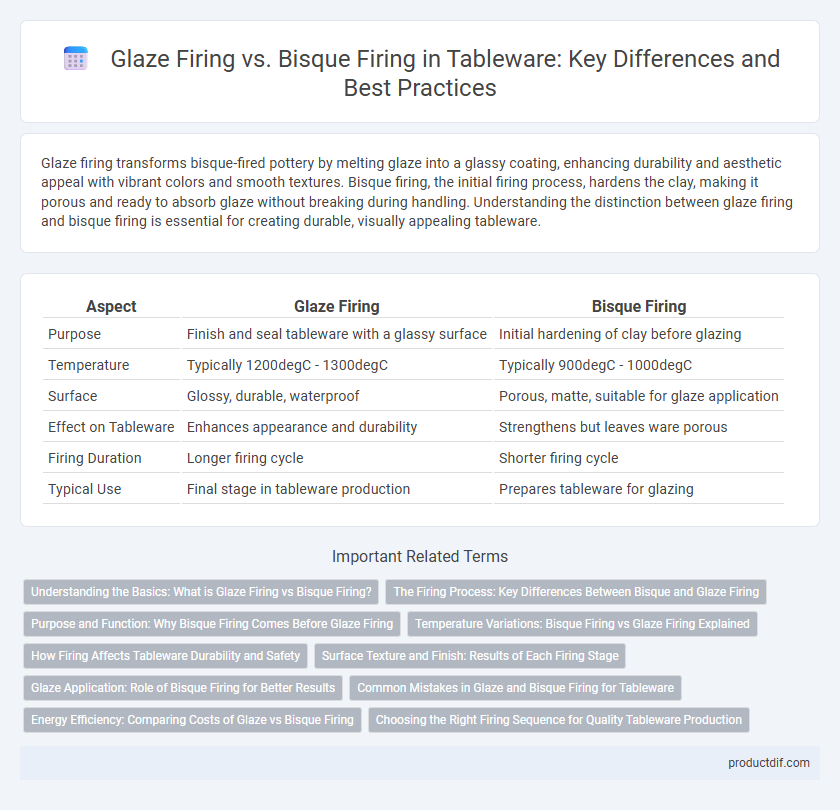

| Aspect | Glaze Firing | Bisque Firing |

|---|---|---|

| Purpose | Finish and seal tableware with a glassy surface | Initial hardening of clay before glazing |

| Temperature | Typically 1200degC - 1300degC | Typically 900degC - 1000degC |

| Surface | Glossy, durable, waterproof | Porous, matte, suitable for glaze application |

| Effect on Tableware | Enhances appearance and durability | Strengthens but leaves ware porous |

| Firing Duration | Longer firing cycle | Shorter firing cycle |

| Typical Use | Final stage in tableware production | Prepares tableware for glazing |

Understanding the Basics: What is Glaze Firing vs Bisque Firing?

Glaze firing and bisque firing are crucial stages in ceramic tableware production, with bisque firing involving the initial kiln heating that transforms shaped clay into porous, hardened bisque ware. Glaze firing follows, where a glassy coating is melted onto the bisque ware's surface, providing durability, waterproofing, and aesthetic appeal. These firings differ in temperature and purpose, with bisque firing typically conducted at lower temperatures (around bisque firing temperature: bisque cone 06 - 1830degF/999degC) and glaze firing requiring higher temperatures (typically cone 06 to cone 10, ranging from 1830degF to 2381degF) to vitrify the glaze effectively.

The Firing Process: Key Differences Between Bisque and Glaze Firing

Bisque firing transforms raw clay into a porous, hardened state by heating it to temperatures between 1730degF and 1940degF, effectively preparing the pottery for glazing. Glaze firing follows bisque firing and occurs at higher temperatures, ranging from 1830degF to 2340degF, melting the glaze to form a glassy, waterproof surface. The key difference lies in bisque firing's role in solidifying the clay body without vitrification, whereas glaze firing finalizes the piece with a durable, sealed finish essential for functional tableware.

Purpose and Function: Why Bisque Firing Comes Before Glaze Firing

Bisque firing transforms greenware clay into a porous, durable state, eliminating moisture and organic material to prevent cracking during subsequent glaze firing. This stage stabilizes the ceramic piece, allowing it to absorb glaze evenly and ensuring proper adhesion without deformation. Glaze firing then vitrifies the glaze and clay body, creating a smooth, glass-like surface that is both waterproof and aesthetically enhanced.

Temperature Variations: Bisque Firing vs Glaze Firing Explained

Bisque firing typically occurs at lower temperatures ranging from 1,650degF to 1,940degF (900degC to 1,060degC), which hardens the clay without vitrifying it, making the pottery porous and ready to absorb glaze. Glaze firing involves higher temperatures, usually between 1,830degF and 2,380degF (1,000degC to 1,300degC), melting the glaze to form a glass-like surface that seals the ceramic piece. Understanding these temperature variations is crucial for achieving desired durability and finish in tableware production.

How Firing Affects Tableware Durability and Safety

Glaze firing creates a glass-like coating that enhances tableware durability by making surfaces non-porous and resistant to chips or stains, significantly improving safety for food contact and cleaning. Bisque firing hardens the clay while maintaining its porous structure, making the tableware fragile and more susceptible to absorbing liquids and bacteria, which compromises long-term safety. The combination of bisque and glaze firing is essential for producing durable, food-safe ceramics suitable for daily use.

Surface Texture and Finish: Results of Each Firing Stage

Bisque firing produces a porous, matte surface that is easy to handle and ideal for applying glaze, with a slightly rough texture that enhances glaze adherence. Glaze firing melts the applied glaze to create a smooth, glass-like, and often glossy or satin finish, sealing the surface and making it non-porous. The contrast between the matte bisque texture and the vitrified, glossy glaze surface defines the final aesthetic and functionality of ceramic tableware.

Glaze Application: Role of Bisque Firing for Better Results

Bisque firing hardens the clay body, creating a porous surface ideal for glaze application, which enhances glaze adherence and vibrancy. Without bisque firing, glaze tends to run or pool unevenly, leading to defects and dull finishes. Proper bisque firing ensures moisture and organic materials are removed, resulting in smoother, more durable glaze surfaces after the final glaze firing.

Common Mistakes in Glaze and Bisque Firing for Tableware

Common mistakes in glaze and bisque firing for tableware include underfiring or overfiring, which can cause cracks, warping, or incomplete glaze maturation. Using inconsistent firing temperatures or poor kiln ventilation often results in dull or blistered surfaces, compromising both aesthetics and durability. Neglecting proper drying or glaze thickness may lead to pinholes, crawling, or glaze peeling, affecting the functional quality of ceramic tableware.

Energy Efficiency: Comparing Costs of Glaze vs Bisque Firing

Glaze firing consumes significantly more energy than bisque firing due to higher temperatures required, often reaching 2300degF compared to bisque firing's 1810degF. The increased fuel usage in glaze firing directly impacts operational costs, making bisque firing more energy-efficient for initial pottery hardening. Choosing the appropriate firing method depends on balancing energy expenditure with the desired finish quality and durability of the ceramic tableware.

Choosing the Right Firing Sequence for Quality Tableware Production

Glaze firing and bisque firing are critical stages in the tableware production process, with bisque firing solidifying the shaped clay and glaze firing applying and maturing the surface finish. Selecting the correct firing sequence ensures durability, vitrification, and optimal aesthetic qualities of ceramic tableware, preventing issues like warping or glaze defects. Manufacturers prioritize controlled temperature ramps and firing atmospheres tailored to specific clay bodies and glaze formulations to enhance product quality and consistency.

Glaze Firing vs Bisque Firing Infographic

productdif.com

productdif.com