Resin clips offer a lightweight, flexible alternative to metal clips, reducing the risk of paper damage and ensuring a secure hold without rusting. Metal clips provide superior durability and strength, making them ideal for heavy-duty use and long-lasting performance. Choosing between resin and metal clips depends on the need for gentleness versus robustness in organizing documents.

Table of Comparison

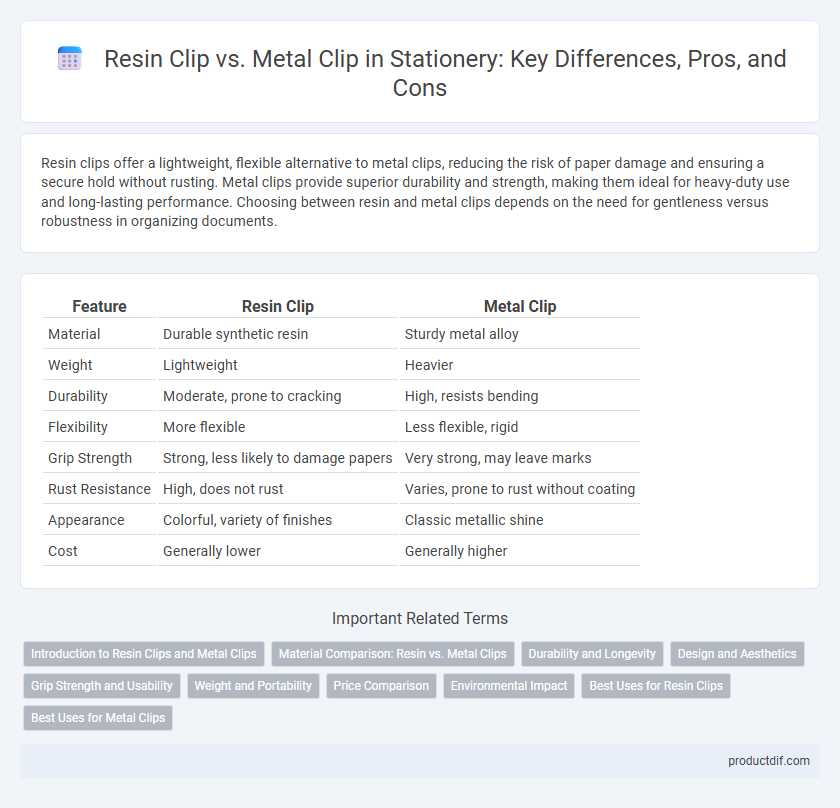

| Feature | Resin Clip | Metal Clip |

|---|---|---|

| Material | Durable synthetic resin | Sturdy metal alloy |

| Weight | Lightweight | Heavier |

| Durability | Moderate, prone to cracking | High, resists bending |

| Flexibility | More flexible | Less flexible, rigid |

| Grip Strength | Strong, less likely to damage papers | Very strong, may leave marks |

| Rust Resistance | High, does not rust | Varies, prone to rust without coating |

| Appearance | Colorful, variety of finishes | Classic metallic shine |

| Cost | Generally lower | Generally higher |

Introduction to Resin Clips and Metal Clips

Resin clips, made from durable plastic materials, offer lightweight and flexible fastening solutions commonly used in everyday stationery for organizing papers. Metal clips, typically crafted from stainless steel or aluminum, provide stronger grip and higher durability, making them ideal for holding larger stacks of documents securely. Both types of clips serve distinct purposes, with resin clips favored for casual use and metal clips preferred for professional, heavy-duty tasks.

Material Comparison: Resin vs. Metal Clips

Resin clips offer lightweight durability and flexibility, making them less prone to bending or breaking under everyday use. Metal clips provide superior strength and a sleek, professional appearance, but may be susceptible to rust or deformation over time. Choosing between resin and metal clips depends on the need for resilience versus aesthetic and structural rigidity in stationery applications.

Durability and Longevity

Resin clips offer lightweight flexibility but generally lack the durability and longevity of metal clips, which resist deformation and corrosion over extended use. Metal clips, often made from stainless steel or coated alloys, maintain their grip strength and structural integrity, making them ideal for heavy-duty or long-term applications. The choice between resin and metal clips significantly impacts the lifespan and reliability of stationery binding solutions.

Design and Aesthetics

Resin clips offer vibrant color options and smooth finishes that enhance modern desk setups, while metal clips provide a sleek, polished look with a classic, industrial appeal. Resin's lightweight nature allows for creative shapes and translucency effects, contrasting with metal clips' durability and minimalistic design. Both materials serve functional purposes, but resin is favored for customizable aesthetics, whereas metal emphasizes timeless elegance.

Grip Strength and Usability

Resin clips offer moderate grip strength suitable for lightweight documents, while metal clips provide superior grip strength, securely holding thicker stacks of paper without slipping. Resin clips tend to be lighter and less prone to rust, enhancing usability in environments prone to moisture, whereas metal clips offer greater durability and longevity for frequent use. Choosing between resin and metal clips depends on the balance between grip strength requirements and the intended frequency and conditions of use.

Weight and Portability

Resin clips offer lightweight convenience, making them ideal for portable stationery kits where minimal weight is essential. Metal clips tend to be heavier but provide greater durability and a stronger grip for securing thicker stacks of paper. For users prioritizing portability, resin clips deliver enhanced ease of transport without sacrificing basic functionality.

Price Comparison

Resin clips typically cost less than metal clips due to lower manufacturing expenses and affordable raw materials. Metal clips offer greater durability but come with a higher price point influenced by metal quality and processing. Choosing between resin and metal clips depends on budget constraints and the required longevity of the stationery item.

Environmental Impact

Resin clips, typically made from plastic polymers, have a lower environmental impact during production due to reduced energy consumption but pose challenges in biodegradability and contribute to plastic waste. Metal clips, often made from steel or aluminum, require more energy-intensive extraction and manufacturing processes but are highly recyclable and less likely to persist in the environment. Choosing metal clips supports circular economy principles by enabling material recovery and reducing landfill dependency compared to resin clips.

Best Uses for Resin Clips

Resin clips are best suited for lightweight paper stacking and frequent repositioning due to their flexibility and gentle grip that prevents damage to delicate documents. Ideal for organizing reports, school assignments, and thin booklets, resin clips offer a colorful and durable alternative to metal clips that can rust or leave indentations. Their corrosion-resistant properties make resin clips perfect for use in humid environments or alongside archival materials where preservation is crucial.

Best Uses for Metal Clips

Metal clips offer superior durability and strong holding power, making them ideal for securing thick stacks of documents or heavy papers in office and industrial settings. Their corrosion resistance and sleek design also contribute to a professional appearance, suitable for presentation materials and formal files. Metal clips are preferred for repetitive use where maintaining a firm grip without damage to papers is essential.

Resin Clip vs Metal Clip Infographic

productdif.com

productdif.com