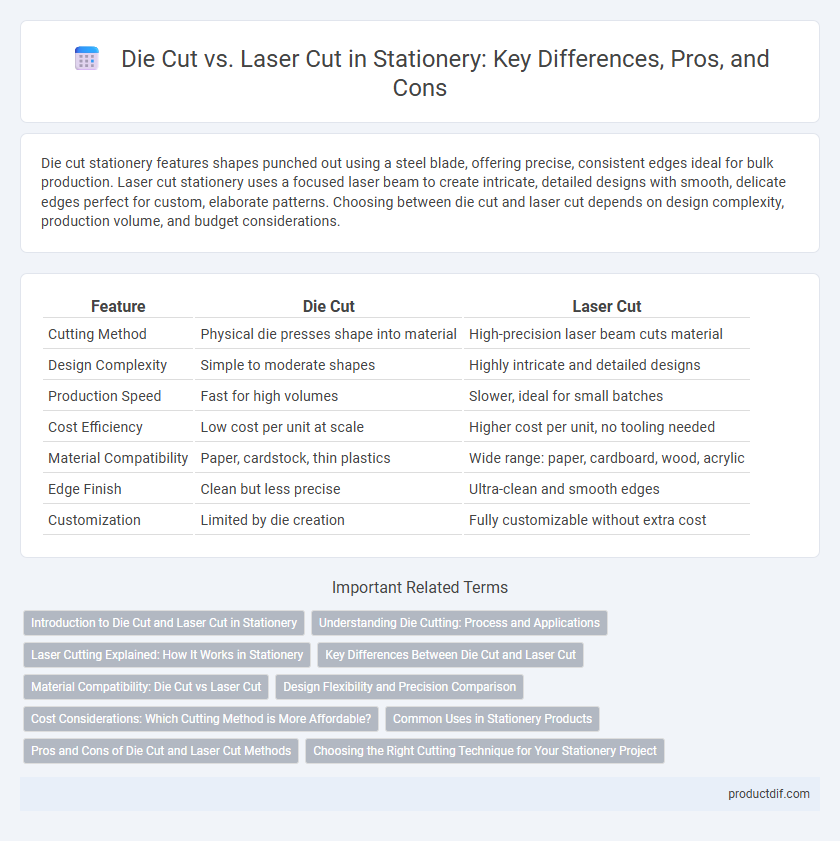

Die cut stationery features shapes punched out using a steel blade, offering precise, consistent edges ideal for bulk production. Laser cut stationery uses a focused laser beam to create intricate, detailed designs with smooth, delicate edges perfect for custom, elaborate patterns. Choosing between die cut and laser cut depends on design complexity, production volume, and budget considerations.

Table of Comparison

| Feature | Die Cut | Laser Cut |

|---|---|---|

| Cutting Method | Physical die presses shape into material | High-precision laser beam cuts material |

| Design Complexity | Simple to moderate shapes | Highly intricate and detailed designs |

| Production Speed | Fast for high volumes | Slower, ideal for small batches |

| Cost Efficiency | Low cost per unit at scale | Higher cost per unit, no tooling needed |

| Material Compatibility | Paper, cardstock, thin plastics | Wide range: paper, cardboard, wood, acrylic |

| Edge Finish | Clean but less precise | Ultra-clean and smooth edges |

| Customization | Limited by die creation | Fully customizable without extra cost |

Introduction to Die Cut and Laser Cut in Stationery

Die cut and laser cut are two precise cutting techniques used in stationery production to create custom shapes and designs. Die cutting uses a pre-shaped metal blade to stamp out shapes from paper or cardstock, ideal for mass production of consistent, intricate patterns. Laser cutting employs a focused laser beam to cut or etch materials, enabling high-detail customization and complex designs on various stationery items such as cards, invitations, and packaging.

Understanding Die Cutting: Process and Applications

Die cutting is a manufacturing process that uses a specialized die to cut precise shapes and designs from various materials, including paper, cardboard, and cardstock, commonly used in stationery production. This method allows for high-volume, consistent, and intricate cuts, ideal for creating custom packaging, labels, and decorative elements. Applications of die cutting extend to producing business cards, envelopes, and promotional materials that require precise and repeatable shapes, enhancing the overall aesthetic and functionality of stationery products.

Laser Cutting Explained: How It Works in Stationery

Laser cutting in stationery uses a high-powered laser beam to precisely cut or engrave materials like paper, cardstock, and thin plastics. This technology achieves intricate designs with clean edges by vaporizing material along the cut path without physical contact, allowing for detailed patterns and custom shapes. It offers faster production, minimal material waste, and superior precision compared to traditional die cutting methods.

Key Differences Between Die Cut and Laser Cut

Die cut uses custom-made metal dies to mechanically stamp shapes, offering precise, repeatable cuts ideal for high-volume production, while laser cut employs focused laser beams for intricate, detailed designs with clean edges, suitable for small batches and complex patterns. Die cutting excels in speed and cost-efficiency for simple shapes, whereas laser cutting provides versatility and precision for unique, detailed designs without the need for tooling. The choice between die cut and laser cut depends on production volume, design complexity, and budget considerations in stationery manufacturing.

Material Compatibility: Die Cut vs Laser Cut

Die cut processes excel with thicker materials like cardstock, foam, and leather, providing precise shapes without fraying edges. Laser cutting offers superior compatibility with a wider range of materials, including wood, acrylic, fabric, and delicate papers, enabling intricate designs with clean, sealed edges. Choosing between die cut and laser cut depends heavily on the material type and desired edge finish for stationery projects.

Design Flexibility and Precision Comparison

Die cut stationery offers exceptional design flexibility with the ability to create intricate shapes, layered effects, and custom patterns tailored to specific branding needs. Laser cut stationery excels in precision, enabling extremely fine details and clean edges that traditional die cutting cannot achieve, making it ideal for delicate and complex designs. While die cutting is cost-effective for larger quantities, laser cutting provides superior accuracy and versatility for unique, high-end stationery products.

Cost Considerations: Which Cutting Method is More Affordable?

Die cut stationery offers a more affordable option for high-volume production due to its faster setup and lower per-unit cost, making it ideal for bulk orders with consistent shapes. Laser cut stationery involves higher upfront costs because of advanced technology and longer production times but allows for intricate, custom designs without the need for physical dies. When budget is a priority and designs are simple, die cutting is more cost-effective; laser cutting is better suited for smaller runs requiring detailed precision despite higher expenses.

Common Uses in Stationery Products

Die cut is commonly used for creating custom-shaped stickers, labels, and packaging due to its ability to produce consistent and intricate shapes at high volume. Laser cut offers precision for delicate details in premium stationery items such as invitations, business cards, and decorative tags, enabling complex designs and fine edges. Both techniques enhance product presentation and functionality, with die cutting preferred for mass production and laser cutting favored for intricate, small-batch projects.

Pros and Cons of Die Cut and Laser Cut Methods

Die cut methods excel in producing large volumes of stationery items with consistent shapes and clean edges, offering cost-effective and efficient production for bulk orders; however, they require custom dies which can be expensive and limit design flexibility. Laser cutting allows for intricate, precise designs with rapid prototyping and minimal setup time, but it may result in slower production speeds and higher costs for large quantities. Choosing between die cut and laser cut depends on the balance between design complexity, production volume, and budget constraints in stationery manufacturing.

Choosing the Right Cutting Technique for Your Stationery Project

Die cut produces precise, custom shapes by stamping through materials, ideal for large quantities and intricate patterns in stationery projects. Laser cut uses focused laser beams to create detailed, clean edges suitable for complex designs and smaller production runs. Choosing between die cut and laser cut depends on project scale, design complexity, and material type to ensure optimal quality and efficiency.

Die Cut vs Laser Cut Infographic

productdif.com

productdif.com