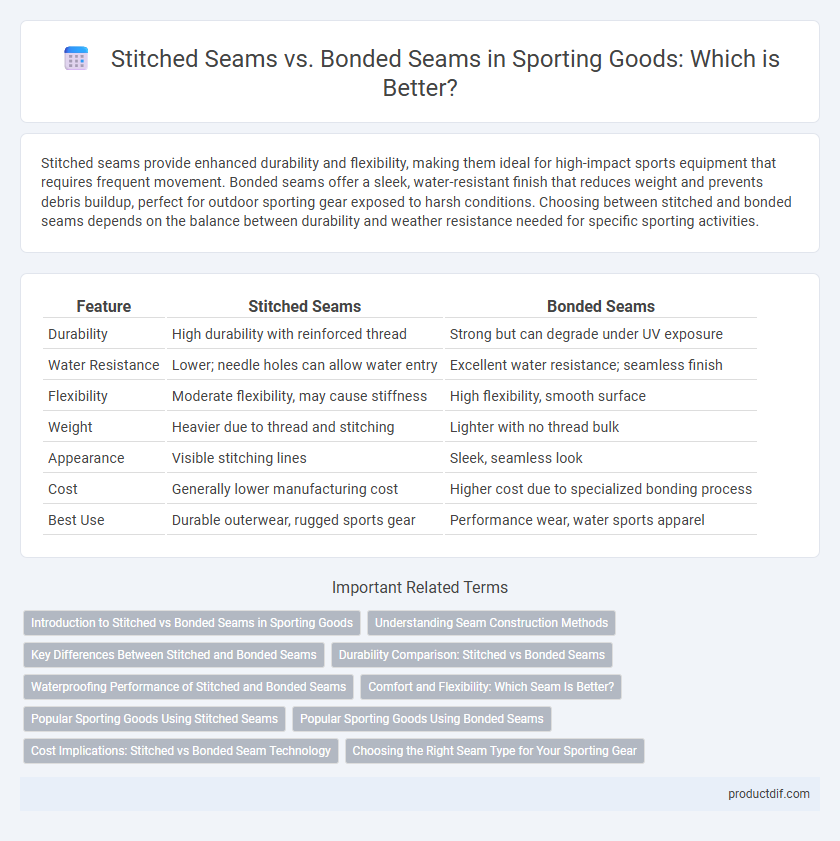

Stitched seams provide enhanced durability and flexibility, making them ideal for high-impact sports equipment that requires frequent movement. Bonded seams offer a sleek, water-resistant finish that reduces weight and prevents debris buildup, perfect for outdoor sporting gear exposed to harsh conditions. Choosing between stitched and bonded seams depends on the balance between durability and weather resistance needed for specific sporting activities.

Table of Comparison

| Feature | Stitched Seams | Bonded Seams |

|---|---|---|

| Durability | High durability with reinforced thread | Strong but can degrade under UV exposure |

| Water Resistance | Lower; needle holes can allow water entry | Excellent water resistance; seamless finish |

| Flexibility | Moderate flexibility, may cause stiffness | High flexibility, smooth surface |

| Weight | Heavier due to thread and stitching | Lighter with no thread bulk |

| Appearance | Visible stitching lines | Sleek, seamless look |

| Cost | Generally lower manufacturing cost | Higher cost due to specialized bonding process |

| Best Use | Durable outerwear, rugged sports gear | Performance wear, water sports apparel |

Introduction to Stitched vs Bonded Seams in Sporting Goods

Stitched seams in sporting goods rely on traditional sewing techniques that offer high durability and flexibility, essential for withstand intense physical activities. Bonded seams use adhesives to fuse materials, resulting in a lightweight, waterproof finish often found in high-performance gear like running jackets and wetsuits. Choosing between stitched and bonded seams affects product performance, comfort, and longevity, making seam technology a critical factor in sporting equipment design.

Understanding Seam Construction Methods

Stitched seams use thread to join fabric pieces, providing flexibility and durability suitable for high-movement sporting goods. Bonded seams rely on adhesives or heat to fuse fabrics, offering a sleek, water-resistant finish ideal for lightweight and aerodynamic gear. Understanding these seam construction methods helps optimize performance, comfort, and longevity in sports apparel and equipment.

Key Differences Between Stitched and Bonded Seams

Stitched seams use thread to join fabric pieces, offering flexibility and traditional durability commonly found in sportswear and outdoor gear. Bonded seams utilize adhesives or heat pressing to fuse fabrics, creating a sleek, waterproof finish favored in high-performance athletic apparel. The primary differences focus on breathability, water resistance, and the degree of seam strength, with stitched seams excelling in flexibility and bonded seams providing superior protection against moisture.

Durability Comparison: Stitched vs Bonded Seams

Stitched seams in sporting goods offer strong mechanical bonding with visible thread patterns that can withstand high stress and repeated flexing, making them highly durable for heavy-duty use. Bonded seams rely on adhesives and heat to fuse materials, providing a sleek and waterproof finish but can be more susceptible to wear and degradation over time compared to stitched seams. For long-term durability and resistance to physical abrasion, stitched seams generally outperform bonded seams in demanding sports environments.

Waterproofing Performance of Stitched and Bonded Seams

Stitched seams create small needle holes that can allow water to penetrate, reducing the waterproofing performance of sporting goods such as jackets and tents. Bonded seams use adhesives or heat to fuse fabric layers together, eliminating needle holes and significantly enhancing waterproof integrity. This makes bonded seams ideal for high-performance waterproof gear, offering superior protection against moisture compared to traditional stitched seams.

Comfort and Flexibility: Which Seam Is Better?

Stitched seams provide enhanced durability and flexibility, allowing garments to move naturally with the body, which is essential for athletes requiring a full range of motion. Bonded seams offer a smoother finish and reduced chafing, increasing comfort during prolonged physical activity by minimizing irritation. For optimal performance in sporting goods, choosing between stitched and bonded seams depends on prioritizing either maximum flexibility or seamless comfort.

Popular Sporting Goods Using Stitched Seams

Popular sporting goods such as soccer balls, baseball gloves, and basketballs use stitched seams for enhanced durability and flexibility, allowing them to withstand intense physical activity. Stitched seams provide superior grip and control, essential for performance in competitive sports. The traditional stitching technique ensures the structural integrity of equipment even under continuous impact and stress.

Popular Sporting Goods Using Bonded Seams

Popular sporting goods using bonded seams include high-performance cycling jerseys, compression wear, and swimwear due to their streamlined design and reduced chafing. Bonded seams enhance durability and flexibility, making them ideal for products that demand frequent movement and moisture management. This seamless construction improves overall comfort and aerodynamics compared to traditional stitched seams.

Cost Implications: Stitched vs Bonded Seam Technology

Stitched seams generally incur higher labor and material costs due to the intricate sewing process and the need for durable threads, increasing production expenses in sporting goods manufacturing. Bonded seams use adhesive technology that reduces sewing time and labor, resulting in lower overall costs and faster production cycles. However, bonded seams may require specialized adhesives and equipment, which can affect initial setup expenses but typically offer long-term savings in mass production.

Choosing the Right Seam Type for Your Sporting Gear

Stitched seams provide durability and flexibility, ideal for high-impact sports where gear undergoes frequent stress and movement. Bonded seams offer a sleek, water-resistant finish that enhances aerodynamic performance in activities like cycling and swimming. Selecting the right seam type depends on the sport's specific demands for strength, flexibility, and moisture resistance to ensure optimal gear performance.

Stitched seams vs bonded seams Infographic

productdif.com

productdif.com