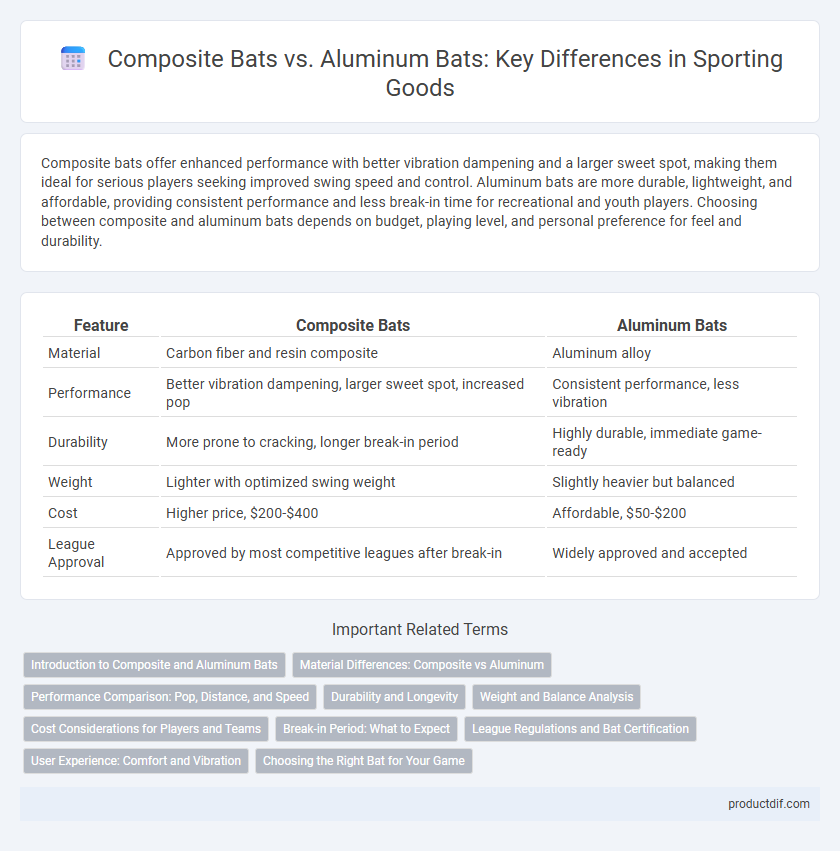

Composite bats offer enhanced performance with better vibration dampening and a larger sweet spot, making them ideal for serious players seeking improved swing speed and control. Aluminum bats are more durable, lightweight, and affordable, providing consistent performance and less break-in time for recreational and youth players. Choosing between composite and aluminum bats depends on budget, playing level, and personal preference for feel and durability.

Table of Comparison

| Feature | Composite Bats | Aluminum Bats |

|---|---|---|

| Material | Carbon fiber and resin composite | Aluminum alloy |

| Performance | Better vibration dampening, larger sweet spot, increased pop | Consistent performance, less vibration |

| Durability | More prone to cracking, longer break-in period | Highly durable, immediate game-ready |

| Weight | Lighter with optimized swing weight | Slightly heavier but balanced |

| Cost | Higher price, $200-$400 | Affordable, $50-$200 |

| League Approval | Approved by most competitive leagues after break-in | Widely approved and accepted |

Introduction to Composite and Aluminum Bats

Composite bats are made from a blend of carbon fiber, resin, and other materials, offering enhanced flexibility, reduced vibration, and a larger sweet spot compared to traditional bats. Aluminum bats, crafted from an aluminum alloy, provide lightweight durability and consistent performance, often preferred in youth and amateur leagues for their affordability and resilience. Both bat types influence swing speed and ball exit velocity differently, impacting player performance and league regulations.

Material Differences: Composite vs Aluminum

Composite bats feature a layered construction of carbon fiber and resin, offering enhanced flexibility and a larger sweet spot compared to aluminum bats, which are typically made from a single piece of hollow aluminum or an aluminum alloy, known for durability and lighter weight. The composite material allows for energy transfer that increases ball speed, while aluminum bats provide immediate power with less vibration upon contact. Differences in material also affect bat longevity; composite bats require a break-in period to reach optimal performance and are more prone to damage from cold temperatures, whereas aluminum bats are ready to use instantly and generally resist environmental wear better.

Performance Comparison: Pop, Distance, and Speed

Composite bats offer enhanced pop and increased distance due to their flexible barrel design, which creates a trampoline effect on the ball. Aluminum bats deliver consistent speed and a lighter swing weight, allowing for quicker bat speed and better control. Performance differences impact player choice based on hitting style, with composites favored for power and distance, while aluminum bats suit those emphasizing bat speed and precision.

Durability and Longevity

Composite bats outperform aluminum bats in durability due to their advanced carbon fiber construction, which resists dents and cracks over time. Their longevity is notable as the composite materials maintain performance levels longer, requiring fewer replacements than aluminum bats. While aluminum bats may show immediate resilience, composite bats develop a "break-in" period enhancing durability and consistent performance across multiple seasons.

Weight and Balance Analysis

Composite bats offer superior weight distribution by incorporating advanced materials that reduce overall bat weight while maintaining strength, enhancing swing speed and control. Aluminum bats tend to be lighter initially but can feel top-heavy due to uniform metal construction, impacting balance and swing mechanics. The balanced design of composite bats provides better maneuverability and improved energy transfer during swings compared to the stiffer feel of aluminum counterparts.

Cost Considerations for Players and Teams

Composite bats generally involve a higher initial investment, often priced between $150 and $500, compared to aluminum bats that range from $50 to $200. The longer break-in period and potential durability issues of composite bats may result in additional costs for players and teams over time. Teams must weigh the upfront cost and maintenance expenses of composite bats against the affordability and resilience of aluminum alternatives when planning their equipment budgets.

Break-in Period: What to Expect

Composite bats require a significant break-in period, typically ranging from 50 to 100 hits, to reach optimal performance as the fibers compress and the bat's barrel becomes more responsive. In contrast, aluminum bats offer immediate performance out of the box with no break-in needed, maintaining consistent pop throughout their lifespan. Players must weigh the initial time investment of composite bats against the instant power and durability of aluminum bats when making their choice.

League Regulations and Bat Certification

League regulations often dictate specific standards for composite and aluminum bats, requiring compliance with certification from organizations like USA Baseball and USSSA to ensure fair play and safety. Composite bats typically undergo rigorous testing for performance metrics such as ball exit speed and durability, aligning with certification criteria that vary by league and age group. Aluminum bats must meet strict certification stamps indicating approval, often influencing bat selection based on league rules and competition level.

User Experience: Comfort and Vibration

Composite bats offer superior vibration dampening technology, significantly reducing hand sting and enhancing overall comfort during play. Aluminum bats, while lighter and more durable, tend to transmit more vibration upon impact, which can cause discomfort for users. Players seeking a smoother, more comfortable hitting experience typically prefer composite bats for their advanced material design that absorbs shock effectively.

Choosing the Right Bat for Your Game

Selecting the right bat for your game depends on factors such as durability, weight distribution, and performance characteristics. Composite bats offer a larger sweet spot and reduced vibration, making them ideal for power hitters seeking maximum distance. Aluminum bats provide superior immediate pop and are typically more affordable, making them suitable for beginners or players looking for a lightweight, responsive option.

Composite bats vs Aluminum bats Infographic

productdif.com

productdif.com