Compression fittings offer easy installation and maintenance without the need for heat, making them ideal for DIY plumbing repairs and temporary connections. Soldered joints provide a more permanent, leak-resistant seal by fusing metal pipes together, ensuring durability in high-pressure water systems. Choosing between compression fittings and soldered joints depends on the specific plumbing fixture requirements, budget, and long-term reliability needs.

Table of Comparison

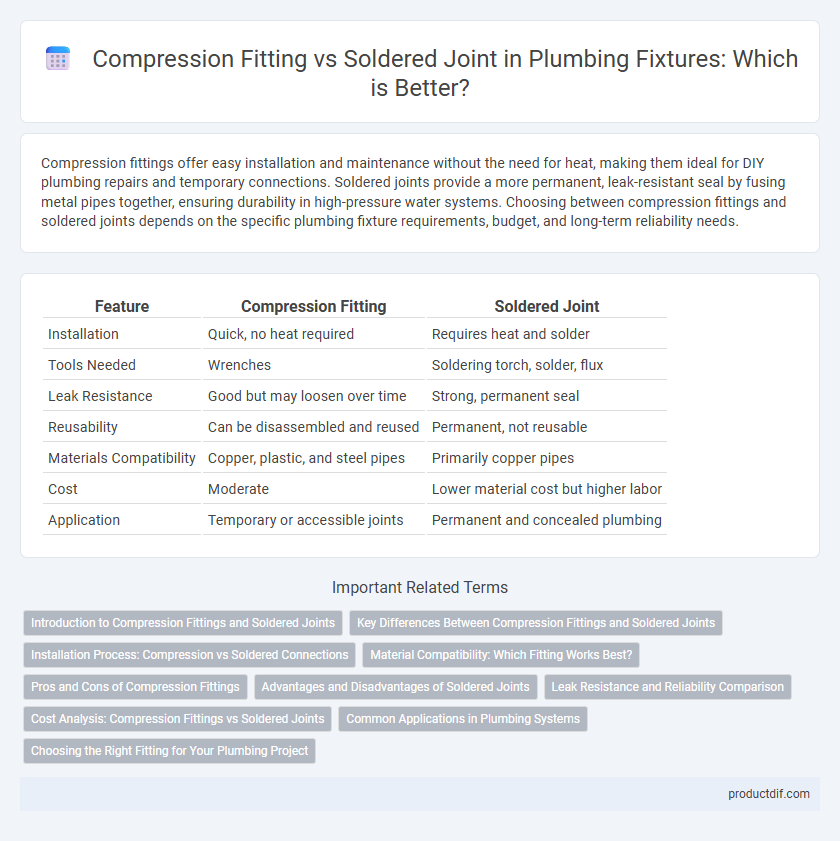

| Feature | Compression Fitting | Soldered Joint |

|---|---|---|

| Installation | Quick, no heat required | Requires heat and solder |

| Tools Needed | Wrenches | Soldering torch, solder, flux |

| Leak Resistance | Good but may loosen over time | Strong, permanent seal |

| Reusability | Can be disassembled and reused | Permanent, not reusable |

| Materials Compatibility | Copper, plastic, and steel pipes | Primarily copper pipes |

| Cost | Moderate | Lower material cost but higher labor |

| Application | Temporary or accessible joints | Permanent and concealed plumbing |

Introduction to Compression Fittings and Soldered Joints

Compression fittings provide a reliable, mechanical method to connect pipes without the need for heat, using a compression ring and nut to seal joints. Soldered joints require heating the pipe and fitting with a torch, melting solder to create a permanent, watertight bond ideal for copper plumbing. Both methods ensure leak-resistant connections, with compression fittings favored for ease and speed, while soldered joints offer long-term durability in various plumbing systems.

Key Differences Between Compression Fittings and Soldered Joints

Compression fittings create a watertight seal by compressing a metal ring onto the pipe, allowing for quick installation without heat or special tools. Soldered joints require heating the pipe and fitting to melt solder into the joint, creating a permanent, leak-proof connection ideal for copper plumbing. Compression fittings are preferred for ease of maintenance and repairs, while soldered joints offer superior durability and long-term reliability.

Installation Process: Compression vs Soldered Connections

Compression fittings offer a straightforward installation process requiring only basic hand tools, making them ideal for quick repairs and DIY projects. Soldered joints demand precise preparation, including cleaning, flux application, and heating with a torch, which ensures a durable, leak-proof seal suitable for permanent plumbing installations. Choosing between compression and soldered connections depends on the installer's skill level, required durability, and whether the application is temporary or permanent.

Material Compatibility: Which Fitting Works Best?

Compression fittings excel with flexible materials like copper, PEX, and CPVC, providing a reliable, non-permanent seal without heat. Soldered joints are ideal for copper pipes, creating a durable, leak-proof connection through metal fusion that is less compatible with plastic materials. Choosing between compression fittings and soldered joints depends on the pipe material and the need for ease of installation versus long-term durability.

Pros and Cons of Compression Fittings

Compression fittings offer the advantage of easy installation without the need for heat, making them ideal for DIY projects and repairs in confined spaces. They provide a reliable, leak-resistant connection suitable for both metal and plastic pipes but may loosen over time under high vibration or temperature fluctuations. Compared to soldered joints, compression fittings can be quickly disassembled for maintenance, though they typically have lower pressure ratings and may require periodic retightening.

Advantages and Disadvantages of Soldered Joints

Soldered joints offer a strong, permanent connection that is resistant to leaks and ideal for high-pressure plumbing systems, providing durability and longevity unmatched by compression fittings. The process requires specialized tools and skills, increasing installation time and cost, while heat application can pose risks to nearby materials and components. Despite these challenges, soldered joints ensure a reliable seal essential for copper piping systems in both residential and commercial plumbing.

Leak Resistance and Reliability Comparison

Compression fittings offer reliable leak resistance in plumbing fixtures by creating a tight seal through mechanical compression of a ferrule onto the pipe, making them ideal for quick repairs and moderate pressure systems. Soldered joints provide superior long-term leak resistance and durability due to the metallurgical bond formed between pipes and fittings, ensuring robustness under high-pressure conditions and temperature fluctuations. Choosing between compression fittings and soldered joints depends on the specific plumbing application requirements, with soldered joints preferred for permanent, high-stress installations and compression fittings favored for maintenance-friendly setups.

Cost Analysis: Compression Fittings vs Soldered Joints

Compression fittings generally have a higher upfront cost compared to soldered joints due to the price of specialized components and tools. Soldered joints, while requiring additional time and skill, use less expensive materials like solder and flux, resulting in lower overall costs for large projects. Maintenance costs for compression fittings can be higher over time due to potential leaks, whereas soldered joints tend to offer longer-lasting, cost-effective reliability.

Common Applications in Plumbing Systems

Compression fittings are commonly used in residential plumbing for connecting copper or plastic pipes where easy installation and disassembly are required, such as in water supply lines to faucets and toilets. Soldered joints are preferred in permanent, leak-proof connections within copper piping systems, frequently found in HVAC systems and potable water distribution. Both methods ensure secure connections, but compression fittings offer versatility for repairs, while soldered joints provide durability in high-pressure applications.

Choosing the Right Fitting for Your Plumbing Project

Compression fittings provide a reliable, tool-free installation ideal for quick repairs and projects requiring disassembly, while soldered joints offer a permanent, leak-proof connection best suited for high-pressure plumbing systems. Considering water pressure, pipe material compatibility, and project permanence helps determine the appropriate fitting type. Selecting the right fitting enhances system durability, ensures leak prevention, and reduces future maintenance costs.

Compression Fitting vs Soldered Joint Infographic

productdif.com

productdif.com