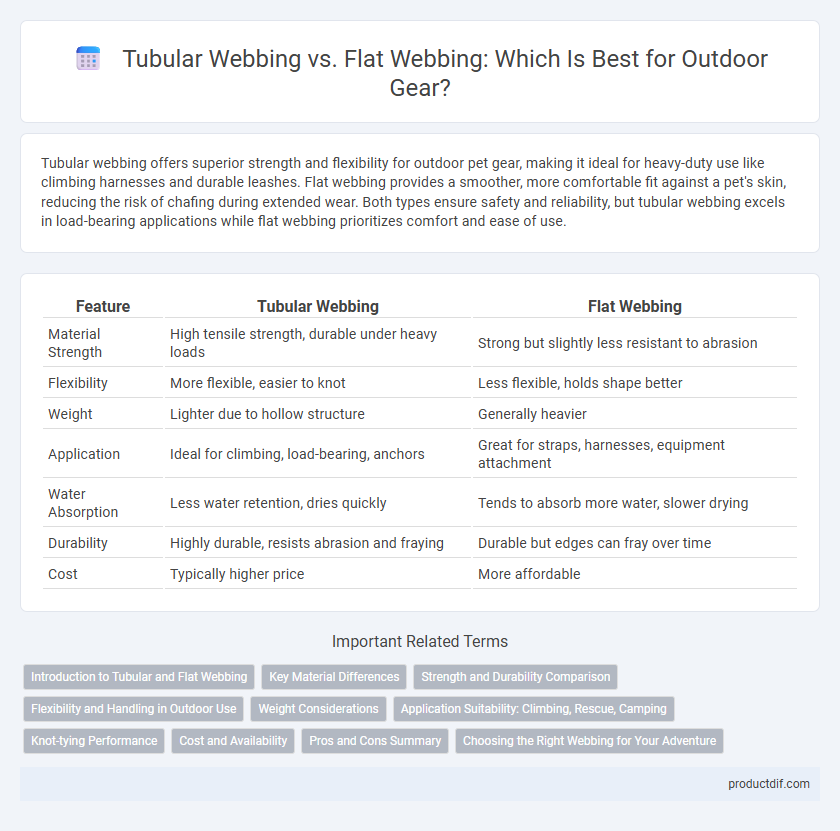

Tubular webbing offers superior strength and flexibility for outdoor pet gear, making it ideal for heavy-duty use like climbing harnesses and durable leashes. Flat webbing provides a smoother, more comfortable fit against a pet's skin, reducing the risk of chafing during extended wear. Both types ensure safety and reliability, but tubular webbing excels in load-bearing applications while flat webbing prioritizes comfort and ease of use.

Table of Comparison

| Feature | Tubular Webbing | Flat Webbing |

|---|---|---|

| Material Strength | High tensile strength, durable under heavy loads | Strong but slightly less resistant to abrasion |

| Flexibility | More flexible, easier to knot | Less flexible, holds shape better |

| Weight | Lighter due to hollow structure | Generally heavier |

| Application | Ideal for climbing, load-bearing, anchors | Great for straps, harnesses, equipment attachment |

| Water Absorption | Less water retention, dries quickly | Tends to absorb more water, slower drying |

| Durability | Highly durable, resists abrasion and fraying | Durable but edges can fray over time |

| Cost | Typically higher price | More affordable |

Introduction to Tubular and Flat Webbing

Tubular webbing consists of a hollow, rounded structure that provides superior strength and abrasion resistance, making it ideal for climbing harnesses and load-bearing applications. Flat webbing features a solid, woven design that offers flexibility and ease of knotting, commonly used for straps, tie-downs, and gear loops. Choosing between tubular and flat webbing depends on the specific strength requirements and functionality needed for outdoor gear tasks.

Key Material Differences

Tubular webbing is constructed from woven strips forming a hollow core, providing enhanced strength, flexibility, and abrasion resistance compared to flat webbing, which is made from a single flat weave. The synthetic fibers in tubular webbing, usually nylon or polyester, offer better load distribution and durability in climbing, hiking, and rescue gear. Flat webbing, although lighter and easier to sew, is prone to cuts and wear, making tubular webbing the preferred choice for high-stress outdoor applications.

Strength and Durability Comparison

Tubular webbing typically offers superior strength and durability compared to flat webbing due to its hollow core design, which distributes load stress more evenly and resists abrasions better. Flat webbing can be prone to edge fraying and less effective in load-bearing applications, making tubular webbing the preferred choice for climbing, rescue operations, and heavy-duty outdoor gear. The enhanced resistance to wear and tear in tubular webbing extends its lifespan, ensuring reliability under extreme conditions.

Flexibility and Handling in Outdoor Use

Tubular webbing offers superior flexibility and ease of handling compared to flat webbing, making it ideal for outdoor activities like climbing and camping where maneuverability is crucial. Its rounded structure allows for smoother knots and reduced wear, enhancing durability under dynamic loads. Flat webbing, while less flexible, provides a broader surface area that distributes pressure evenly but can be stiffer and more challenging to manipulate in tight or complex setups.

Weight Considerations

Tubular webbing typically weighs more than flat webbing due to its hollow core construction, which adds bulk without significantly increasing strength. Flat webbing is favored in ultralight backpacking and climbing applications where every gram matters, as it provides adequate tensile strength with less material. Choosing between tubular and flat webbing depends on balancing weight savings against durability and abrasion resistance for specific outdoor gear needs.

Application Suitability: Climbing, Rescue, Camping

Tubular webbing offers superior strength and durability, making it ideal for climbing and rescue operations where load-bearing capacity and knot security are critical. Flat webbing provides a lightweight, flexible option better suited for camping applications like securing gear or creating makeshift straps. Choosing between tubular and flat webbing depends on the specific demands of the activity, with tubular favored for high-stress environments and flat preferred for versatility and ease of use.

Knot-tying Performance

Tubular webbing offers superior knot-tying performance due to its rounded structure, which allows knots to cinch tighter and maintain strength under load, making it ideal for climbing and anchoring. Flat webbing, while easier to handle and less bulky, can be prone to slipping and less secure knots, impacting safety in critical outdoor applications. Tubular webbing's durability and resistance to abrasion further enhance knot integrity during prolonged use in rugged outdoor environments.

Cost and Availability

Tubular webbing generally costs more than flat webbing due to its enhanced strength and durability, making it a preferred choice for critical load-bearing applications. Flat webbing is widely available and often less expensive, making it suitable for budget-conscious outdoor gear users. Both types are commonly found in outdoor equipment stores, but tubular webbing's price premium reflects its specialized construction.

Pros and Cons Summary

Tubular webbing offers superior strength and abrasion resistance, making it ideal for climbing and heavy-duty applications, while flat webbing provides better grip and is easier to tie knots, suited for load distribution and lightweight gear. Tubular webbing resists twisting and is more durable but can be bulkier and less breathable compared to flat webbing. Flat webbing's planar design enhances comfort and flexibility but may degrade faster under constant abrasion or high tension.

Choosing the Right Webbing for Your Adventure

Tubular webbing offers superior strength and flexibility, making it ideal for climbing and load-bearing activities where durability and knot security are critical. Flat webbing provides a broader surface area, which distributes pressure more evenly and is often preferred for harnesses and slings used in hiking and camping. Selecting the right webbing depends on the specific demands of your adventure, prioritizing factors like weight capacity, abrasion resistance, and ease of handling.

Tubular webbing vs flat webbing Infographic

productdif.com

productdif.com