Thermal label printers offer fast, quiet printing with high-resolution labels ideal for barcode and shipping applications, while dot matrix printers excel in multi-part forms and environments requiring carbon copies. Thermal printers require special heat-sensitive paper but deliver low maintenance and high print quality, whereas dot matrix printers can use regular paper and are more durable in harsh industrial settings. Choosing between them depends on the specific office supply needs, such as print volume, label types, and required print clarity.

Table of Comparison

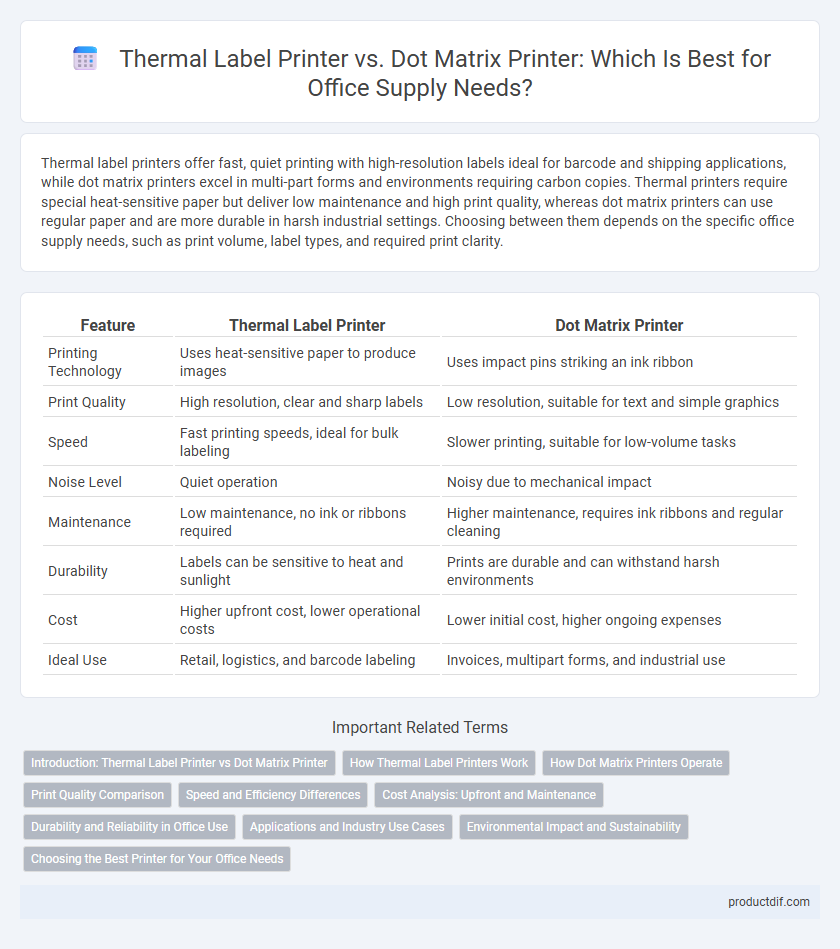

| Feature | Thermal Label Printer | Dot Matrix Printer |

|---|---|---|

| Printing Technology | Uses heat-sensitive paper to produce images | Uses impact pins striking an ink ribbon |

| Print Quality | High resolution, clear and sharp labels | Low resolution, suitable for text and simple graphics |

| Speed | Fast printing speeds, ideal for bulk labeling | Slower printing, suitable for low-volume tasks |

| Noise Level | Quiet operation | Noisy due to mechanical impact |

| Maintenance | Low maintenance, no ink or ribbons required | Higher maintenance, requires ink ribbons and regular cleaning |

| Durability | Labels can be sensitive to heat and sunlight | Prints are durable and can withstand harsh environments |

| Cost | Higher upfront cost, lower operational costs | Lower initial cost, higher ongoing expenses |

| Ideal Use | Retail, logistics, and barcode labeling | Invoices, multipart forms, and industrial use |

Introduction: Thermal Label Printer vs Dot Matrix Printer

Thermal label printers utilize heat to produce images on heat-sensitive paper, offering high-speed, quiet, and maintenance-free printing ideal for barcode labels and shipping tags. Dot matrix printers employ impact technology with a ribbon and pins, delivering durable and multi-part forms suitable for inventory records and invoices. Choosing between thermal label printers and dot matrix printers depends on required print quality, speed, noise level, and specific office supply needs.

How Thermal Label Printers Work

Thermal label printers use heat-sensitive paper and a thermal printhead to produce images by selectively heating specific areas, eliminating the need for ink or toner. This direct thermal printing technology provides fast, quiet, and precise label creation, ideal for barcodes, shipping labels, and product tags. In contrast to dot matrix printers, thermal label printers offer higher resolution and reliability in high-volume office supply environments.

How Dot Matrix Printers Operate

Dot matrix printers operate by striking an ink-soaked ribbon against paper using a print head containing a matrix of pins, creating characters through a pattern of dots. This impact-based mechanism enables multi-part form printing, making dot matrix printers ideal for carbon copy receipts and continuous feed documents. Their durability and low operational cost make them suitable for industrial and office environments where reliability and low maintenance are critical.

Print Quality Comparison

Thermal label printers offer superior print quality with crisp, clear text and sharp barcodes, ideal for precise labeling and professional presentations. Dot matrix printers produce lower-resolution prints with visible dot patterns, resulting in less detail and fuzzier images, suitable mainly for multi-part forms and continuous paper. Thermal technology ensures faster, quieter operation with consistent output, outperforming the older impact method used by dot matrix printers.

Speed and Efficiency Differences

Thermal label printers operate at high speeds, often printing up to 6 inches per second, making them ideal for rapid label production in busy office environments. Dot matrix printers print significantly slower, averaging around 2-4 pages per minute, which can hinder efficiency when handling large volumes of labels or documents. The faster printing capability of thermal label printers directly enhances workflow efficiency, reducing wait times and streamlining office supply management.

Cost Analysis: Upfront and Maintenance

Thermal label printers typically have higher upfront costs ranging from $200 to $600 but offer lower maintenance expenses due to fewer moving parts and no ink usage. Dot matrix printers have lower initial prices around $150 to $300 but incur higher ongoing costs from ink ribbons, paper, and frequent part replacements. Over a five-year period, thermal printers generally prove more cost-effective for businesses requiring high-volume, durable label printing.

Durability and Reliability in Office Use

Thermal label printers offer superior durability with fewer moving parts, resulting in less frequent maintenance and longer service life compared to dot matrix printers. Their reliability in office use is enhanced by noise-free operation and consistent print quality, ideal for high-volume label printing. Dot matrix printers, while robust and capable of handling multi-part forms, tend to wear faster due to impact-based printing, making them less suitable for intensive, long-term office applications.

Applications and Industry Use Cases

Thermal label printers excel in retail, logistics, and healthcare industries for printing barcode labels, shipping tags, and patient wristbands with durability and high-speed efficiency. Dot matrix printers are widely used in banking, automotive, and manufacturing sectors for multipart forms, invoices, and continuous feed documents requiring impact printing resilience. Each printer type suits specific operational needs, with thermal printers thriving in fast, clean label production and dot matrix printers excelling in environments demanding carbon-copy and low-cost printing solutions.

Environmental Impact and Sustainability

Thermal label printers consume less energy and produce minimal waste compared to dot matrix printers, which use ink ribbons and continuous paper, generating more pollutants. Thermal printers are quieter and emit no ozone or heat byproducts, contributing to a healthier workplace and reduced environmental footprint. Choosing thermal label printers supports sustainability goals by lowering carbon emissions and reducing consumables waste, aligning with eco-friendly office practices.

Choosing the Best Printer for Your Office Needs

Thermal label printers offer fast, quiet printing with high-resolution output ideal for barcode labels and shipping tags, making them perfect for modern office environments requiring efficiency and professional appearance. Dot matrix printers, known for durability and ability to print multi-part forms, are suitable for offices needing carbon copies or dealing with heavy paper stocks. Selecting the best printer depends on specific office tasks, print volume, and the desired quality of printed materials.

Thermal Label Printer vs Dot Matrix Printer Infographic

productdif.com

productdif.com