Staplers are essential office supplies known for securely fastening multiple sheets of paper with metal staples, providing strong and reliable binding for documents. Stapleless staplers offer an eco-friendly alternative by cutting and folding paper to bind sheets without metal staples, reducing waste and risks of injury. Choosing between the two depends on the need for durability versus sustainability and convenience in everyday office tasks.

Table of Comparison

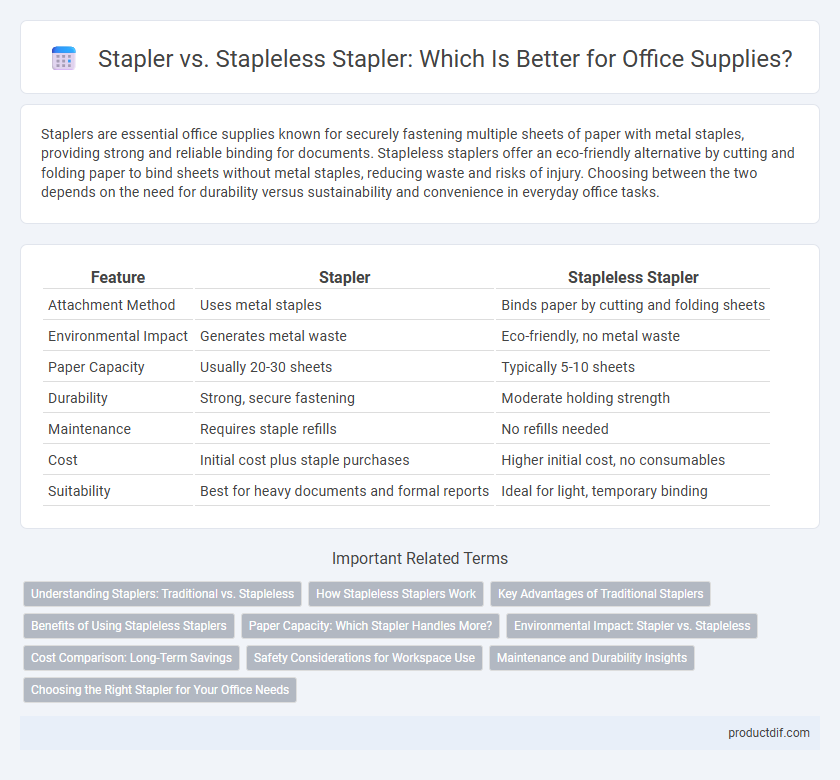

| Feature | Stapler | Stapleless Stapler |

|---|---|---|

| Attachment Method | Uses metal staples | Binds paper by cutting and folding sheets |

| Environmental Impact | Generates metal waste | Eco-friendly, no metal waste |

| Paper Capacity | Usually 20-30 sheets | Typically 5-10 sheets |

| Durability | Strong, secure fastening | Moderate holding strength |

| Maintenance | Requires staple refills | No refills needed |

| Cost | Initial cost plus staple purchases | Higher initial cost, no consumables |

| Suitability | Best for heavy documents and formal reports | Ideal for light, temporary binding |

Understanding Staplers: Traditional vs. Stapleless

Traditional staplers use metal staples to fasten paper, providing strong, durable binding suitable for thick document stacks. Stapleless staplers cut and fold paper edges to secure sheets without metal fasteners, offering an eco-friendly, jam-free alternative for light paper groupings. Choosing between these depends on the need for permanence versus sustainability and convenience in everyday office tasks.

How Stapleless Staplers Work

Stapleless staplers fasten papers by cutting and folding a small flap on the edge of the sheets, creating a secure hold without using metal staples. This eco-friendly method reduces waste and eliminates the need for staple refills, enhancing office sustainability. Their innovative mechanism is ideal for light, temporary paper binding in environments prioritizing safety and recyclability.

Key Advantages of Traditional Staplers

Traditional staplers provide reliable and strong fastening with metal staples, ensuring documents stay securely bound even under heavy handling. They are compatible with various staple sizes, allowing versatile use for different paper thicknesses and project requirements. The mechanical simplicity of traditional staplers offers consistent performance and easy reloading, making them ideal for high-volume office tasks.

Benefits of Using Stapleless Staplers

Stapleless staplers offer enhanced environmental benefits by eliminating the need for metal staples, reducing both waste and the risk of injuries associated with sharp staples. These devices use innovative paper-locking mechanisms that secure documents without damaging paper fibers, promoting easier recycling and document handling. Cost-effective in long-term office supply management, stapleless staplers decrease the dependency on disposable staples and minimize maintenance related to staple jams.

Paper Capacity: Which Stapler Handles More?

Staplers typically handle a higher paper capacity, with standard models stapling between 20 to 30 sheets, while heavy-duty options manage up to 100 sheets or more. Stapleless staplers generally secure fewer sheets, often accommodating only 5 to 10 pages by cutting and folding the paper itself. For tasks requiring binding larger stacks of documents, traditional staplers provide superior capacity and durability.

Environmental Impact: Stapler vs. Stapleless

Staplers require metal staples, generating waste that contributes to landfill accumulation and resource consumption through metal production. Stapleless staplers mechanically bind paper by cutting and folding sheets together, eliminating metal waste and reducing environmental footprint. Choosing stapleless staplers supports sustainable office practices by minimizing reliance on non-recyclable materials and reducing overall office supply waste.

Cost Comparison: Long-Term Savings

Traditional staplers require continuous purchases of staples, leading to recurring expenses that add up significantly over time. Stapleless staplers eliminate the need for staples entirely, providing a cost-effective alternative with minimal maintenance costs. Long-term savings from stapleless staplers result from reduced supply purchases and lower waste disposal fees, making them an economical choice for office supply budgets.

Safety Considerations for Workspace Use

Staplers typically use metal staples that can pose a risk of puncture injuries or accidental scratches, requiring careful handling and disposal to maintain a safe workspace. Stapleless staplers, which bind papers by cutting and folding the sheets without metal staples, significantly reduce injury risks and eliminate the need for staple removal or disposal, enhancing overall office safety. Choosing stapleless staplers supports a safer environment, especially in workplaces with children or high traffic, by minimizing sharp objects and potential hazards.

Maintenance and Durability Insights

Standard staplers require regular replenishment of metal staples and occasional cleaning to prevent jamming, ensuring consistent performance and longevity. Stapleless staplers eliminate the need for staple refills, reducing maintenance efforts while relying on a unique paper folding mechanism that may limit durability under heavy use. Users seeking long-term reliability in high-volume environments often prefer traditional staplers, whereas stapleless models suit low-maintenance, eco-friendly office tasks.

Choosing the Right Stapler for Your Office Needs

Choosing the right stapler for your office needs depends on the volume of paperwork and environmental considerations. Traditional staplers offer strong, durable fastening ideal for large stacks of paper, while stapleless staplers use innovative cutting technology to bind documents without metal staples, reducing waste and improving safety. Evaluate office workflow, document thickness, and sustainability goals to determine whether a classic or stapleless stapler better suits your daily tasks.

Stapler vs Stapleless stapler Infographic

productdif.com

productdif.com