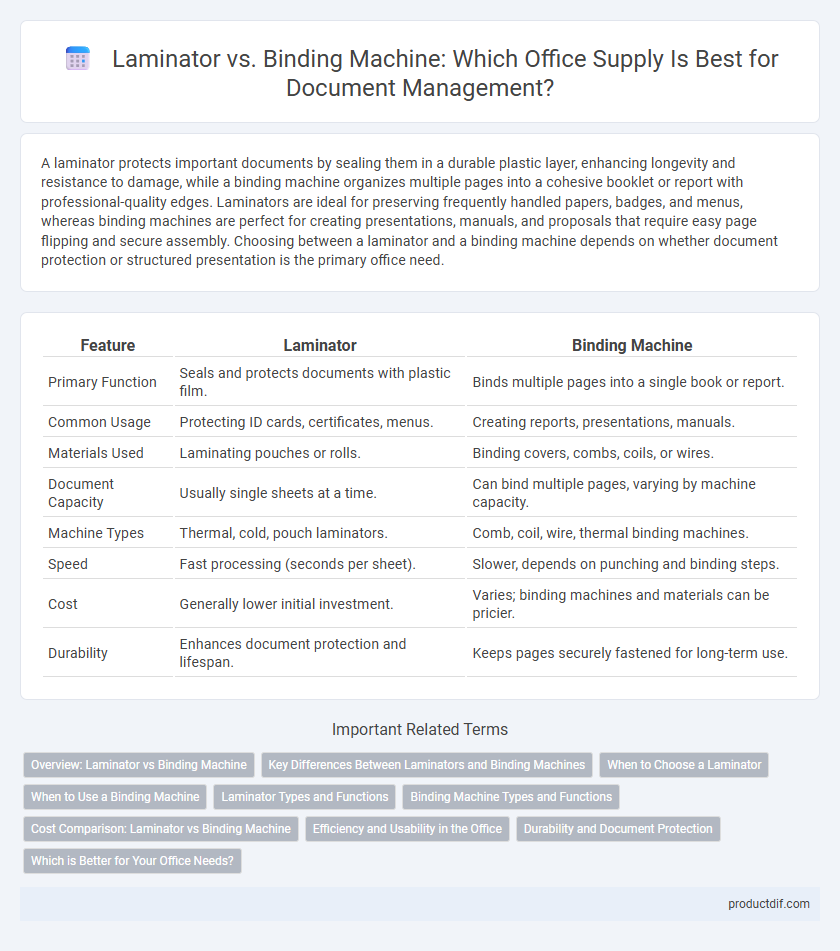

A laminator protects important documents by sealing them in a durable plastic layer, enhancing longevity and resistance to damage, while a binding machine organizes multiple pages into a cohesive booklet or report with professional-quality edges. Laminators are ideal for preserving frequently handled papers, badges, and menus, whereas binding machines are perfect for creating presentations, manuals, and proposals that require easy page flipping and secure assembly. Choosing between a laminator and a binding machine depends on whether document protection or structured presentation is the primary office need.

Table of Comparison

| Feature | Laminator | Binding Machine |

|---|---|---|

| Primary Function | Seals and protects documents with plastic film. | Binds multiple pages into a single book or report. |

| Common Usage | Protecting ID cards, certificates, menus. | Creating reports, presentations, manuals. |

| Materials Used | Laminating pouches or rolls. | Binding covers, combs, coils, or wires. |

| Document Capacity | Usually single sheets at a time. | Can bind multiple pages, varying by machine capacity. |

| Machine Types | Thermal, cold, pouch laminators. | Comb, coil, wire, thermal binding machines. |

| Speed | Fast processing (seconds per sheet). | Slower, depends on punching and binding steps. |

| Cost | Generally lower initial investment. | Varies; binding machines and materials can be pricier. |

| Durability | Enhances document protection and lifespan. | Keeps pages securely fastened for long-term use. |

Overview: Laminator vs Binding Machine

Laminators use heat and pressure to seal documents between plastic films, enhancing durability and protection against moisture and wear. Binding machines secure multiple pages into a book-like format using comb, wire, or coil bindings, ideal for creating professional reports and presentations. Choosing between a laminator and binding machine depends on whether document protection or organized assembly of pages is the primary goal.

Key Differences Between Laminators and Binding Machines

Laminators use heat or cold lamination film to seal documents in protective plastic, enhancing durability and water resistance. Binding machines join multiple pages together by inserting combs, coils, or spines, creating booklets or reports with a professional finish. While laminators prioritize protection and preservation, binding machines focus on organizing and presenting multi-page documents.

When to Choose a Laminator

Choose a laminator when the primary goal is to protect documents from moisture, wear, and tear by sealing them in a durable plastic film. Laminators are ideal for preserving frequently handled items like ID cards, menus, and instructional sheets, ensuring longevity and a professional finish. This makes them essential in environments where durability and water resistance are critical, such as schools, offices, and retail settings.

When to Use a Binding Machine

Use a binding machine when creating professional documents that require a polished, durable finish with customizable cover options. Binding machines are ideal for assembling reports, presentations, and booklets that need to open flat for easy reading or note-taking. They offer various binding styles, such as comb, wire, or thermal, making them suitable for both small office projects and high-volume document preparation.

Laminator Types and Functions

Laminators come in several types, including pouch, roll, and thermal laminators, each designed to protect documents by sealing them between plastic films with heat or pressure. Pouch laminators use pre-sized plastic pouches and are ideal for small or medium-sized items, while roll laminators continuously laminate larger documents or quantities efficiently. Thermal laminators melt adhesive to bond the plastic layers, providing durable and waterproof protection, making them superior for preserving important office materials.

Binding Machine Types and Functions

Binding machines come in various types, including comb, wire, coil, and thermal binders, each offering distinct functions tailored to document finishing needs. Comb binders allow easy editing by opening and closing plastic spines, wire binders provide a professional look with durable metal loops, coil binders enable 360-degree page rotation with a flexible plastic coil, and thermal binders use heat to fuse adhesive strips for a polished, book-like finish. Choosing the right binding machine depends on factors like document volume, desired durability, and the ease of adding or removing pages.

Cost Comparison: Laminator vs Binding Machine

Laminators typically have a lower initial cost ranging from $20 to $150, making them affordable for small offices and occasional use, while binding machines usually cost between $50 and $300, depending on the type and capacity. Operational expenses for laminators include laminating pouches priced around $0.10 to $0.50 each, whereas binding machines require binding combs or coils costing approximately $1 to $3 per unit. Long-term maintenance and consumables often make laminators more budget-friendly for frequent use compared to binding machines that may incur higher ongoing costs due to specialized supplies.

Efficiency and Usability in the Office

Laminators enhance document durability and protection with quick, straightforward operation, making them ideal for preserving frequently handled materials. Binding machines efficiently compile multiple pages into professional-looking presentations, improving organization and presentation quality in meetings. Both tools optimize office workflow, but laminators excel in safeguarding, while binding machines streamline multi-page document management.

Durability and Document Protection

Laminators offer superior durability by sealing documents in a protective plastic layer that guards against moisture, dirt, and wear, making them ideal for preserving frequently handled papers. Binding machines provide strong structural support through various binding methods like comb or wire, enhancing document organization but offering less protection against environmental damage. For long-term document protection, laminators excel in durability by creating a sealed barrier, while binding machines prioritize secure presentation and ease of page flipping.

Which is Better for Your Office Needs?

A laminator protects important documents by sealing them in a plastic film, enhancing durability and water resistance, ideal for frequently handled papers and presentations. A binding machine assembles multiple pages into a single, professional-looking booklet or report, perfect for creating organized manuals or proposals. Choosing between the two depends on whether your office prioritizes document protection or presentation and organization of multi-page materials.

Laminator vs Binding Machine Infographic

productdif.com

productdif.com