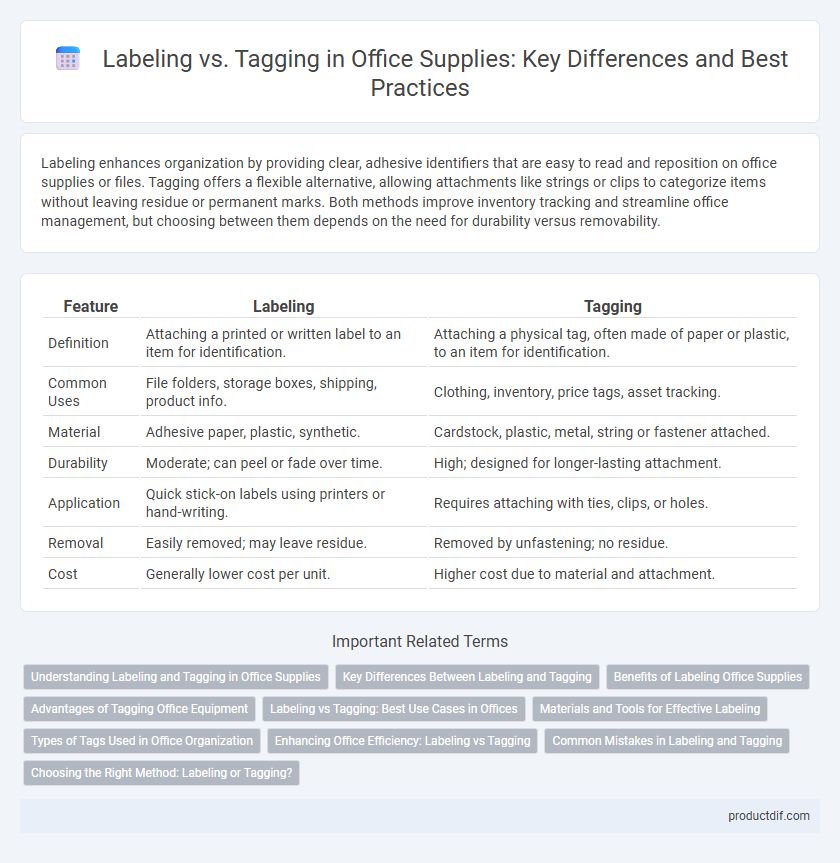

Labeling enhances organization by providing clear, adhesive identifiers that are easy to read and reposition on office supplies or files. Tagging offers a flexible alternative, allowing attachments like strings or clips to categorize items without leaving residue or permanent marks. Both methods improve inventory tracking and streamline office management, but choosing between them depends on the need for durability versus removability.

Table of Comparison

| Feature | Labeling | Tagging |

|---|---|---|

| Definition | Attaching a printed or written label to an item for identification. | Attaching a physical tag, often made of paper or plastic, to an item for identification. |

| Common Uses | File folders, storage boxes, shipping, product info. | Clothing, inventory, price tags, asset tracking. |

| Material | Adhesive paper, plastic, synthetic. | Cardstock, plastic, metal, string or fastener attached. |

| Durability | Moderate; can peel or fade over time. | High; designed for longer-lasting attachment. |

| Application | Quick stick-on labels using printers or hand-writing. | Requires attaching with ties, clips, or holes. |

| Removal | Easily removed; may leave residue. | Removed by unfastening; no residue. |

| Cost | Generally lower cost per unit. | Higher cost due to material and attachment. |

Understanding Labeling and Tagging in Office Supplies

Labeling in office supplies involves attaching adhesive-backed materials with printed information to identify and organize items, enhancing inventory management and ease of access. Tagging refers to the use of non-adhesive tags or markers, often tied or clipped, to provide temporary or movable identification for office assets and documents. Understanding the distinction between labeling and tagging improves office efficiency by ensuring appropriate methods are used based on permanence and item type.

Key Differences Between Labeling and Tagging

Labeling involves attaching printed information directly to an item, such as barcodes, product names, or instructions, to provide clear identification and facilitate inventory management. Tagging typically uses removable or reusable tags that can carry more detailed, variable data like pricing, batch numbers, or status updates, often used for temporary identification. The key differences include permanence, with labeling being more permanent and integrated, while tagging offers flexibility and reusability for dynamic tracking in office supply contexts.

Benefits of Labeling Office Supplies

Labeling office supplies improves organization by clearly identifying items, reducing search time and increasing productivity. It enhances inventory management, enabling quick stock assessments and minimizing overordering or shortages. Labeling also promotes a professional workplace environment by maintaining consistency and clarity in supply identification.

Advantages of Tagging Office Equipment

Tagging office equipment offers enhanced asset management by enabling quick identification and tracking through barcode or RFID technology, reducing inventory errors and loss. It facilitates accurate maintenance schedules and audit trails, improving operational efficiency and accountability. The durability of tags ensures long-term usage under varying office conditions, outperforming traditional labels in reliability.

Labeling vs Tagging: Best Use Cases in Offices

Labeling excels in organizing office files, folders, and storage bins with clear, printable adhesive tags that improve document retrieval and inventory management efficiency. Tagging is ideal for temporarily identifying equipment, cables, or assets with removable or editable tags, facilitating asset tracking and maintenance updates without permanent markings. Both methods enhance office workflow, but labeling suits long-term organization while tagging supports flexible, dynamic identification needs.

Materials and Tools for Effective Labeling

Effective labeling in office supplies relies on durable materials such as adhesive vinyl, polyester, or laminated paper that withstand wear and tear, moisture, and fading. Essential tools include thermal label printers, high-quality permanent markers, and label applicators, ensuring precise and long-lasting identification. Choosing the right combination of materials and tools enhances organization, retrieval efficiency, and product longevity in office environments.

Types of Tags Used in Office Organization

Tags used in office organization include adhesive labels, string tags, and plastic loop tags, each designed for specific identification and categorization purposes. Adhesive labels offer a permanent solution for files and storage boxes, while string tags provide flexible attachment options for items like cables and equipment. Plastic loop tags are durable and reusable, ideal for tracking office assets and inventory efficiently.

Enhancing Office Efficiency: Labeling vs Tagging

Labeling and tagging both streamline office efficiency by organizing supplies and documents for quick identification, reducing search time and minimizing errors. Labels typically offer clear, adhesive information on files and containers, enhancing visual management, while tags, often attached with strings or fasteners, provide flexible identification for movable items. Choosing between labeling or tagging depends on the office's workflow needs, ensuring optimized inventory control and improved task accuracy.

Common Mistakes in Labeling and Tagging

Common mistakes in labeling include using illegible fonts, inconsistent sizes, and poor adhesive quality, which lead to difficulty in identification and increased errors. Tagging errors often involve incorrect or incomplete information, improper placement, and failure to update tags promptly, resulting in miscommunication and inventory inaccuracies. Ensuring clear, durable labels and accurate, timely tags enhances organization and operational efficiency in office supply management.

Choosing the Right Method: Labeling or Tagging?

Choosing the right method between labeling and tagging depends on the specific office supply needs, such as durability, visibility, and ease of application. Labels offer versatile surface adhesion suitable for files and folders, promoting clear identification and organization. Tags provide enhanced durability for bulkier items or inventory that requires frequent handling and may demand attachment methods like string or plastic loops.

Labeling vs Tagging Infographic

productdif.com

productdif.com