Label makers provide customizable labeling solutions ideal for organizing office supplies, files, and personal items with clear, durable tags. Barcode scanners optimize inventory management by quickly capturing and processing product information, enhancing accuracy and efficiency in stock control. Choosing between the two depends on whether the priority is streamlined organization or fast, data-driven inventory tracking.

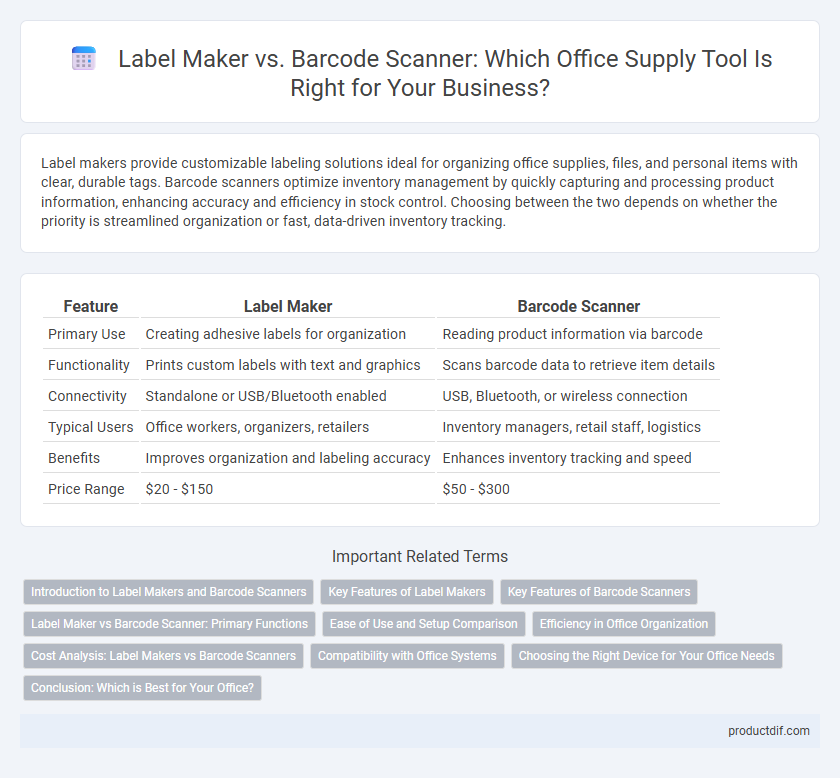

Table of Comparison

| Feature | Label Maker | Barcode Scanner |

|---|---|---|

| Primary Use | Creating adhesive labels for organization | Reading product information via barcode |

| Functionality | Prints custom labels with text and graphics | Scans barcode data to retrieve item details |

| Connectivity | Standalone or USB/Bluetooth enabled | USB, Bluetooth, or wireless connection |

| Typical Users | Office workers, organizers, retailers | Inventory managers, retail staff, logistics |

| Benefits | Improves organization and labeling accuracy | Enhances inventory tracking and speed |

| Price Range | $20 - $150 | $50 - $300 |

Introduction to Label Makers and Barcode Scanners

Label makers are handheld or desktop devices designed to create adhesive labels for organizing files, shelves, and inventory, utilizing thermal or inkjet printing technology. Barcode scanners use laser or imaging technology to read and decode barcode information, streamlining inventory management and point-of-sale operations. Both tools enhance office efficiency by improving product identification and tracking accuracy.

Key Features of Label Makers

Label makers offer versatile printing capabilities, allowing users to create custom labels with various fonts, sizes, and symbols for enhanced organization in office settings. High-resolution thermal printing ensures clear, durable labels that resist smudging and fading, ideal for asset tagging and file management. Many models include built-in keyboards and LCD displays, enabling quick label editing and preview before printing, which improves efficiency in labeling tasks.

Key Features of Barcode Scanners

Barcode scanners excel in quickly reading and decoding barcodes with high accuracy, enabling efficient inventory management and sales transactions. Key features include laser or image-based scanning technology, multi-barcode format compatibility, wireless connectivity options like Bluetooth, and ergonomic designs for prolonged use. These scanners also support rapid data transmission to various systems, enhancing workflow automation and reducing human error in office supply tracking.

Label Maker vs Barcode Scanner: Primary Functions

Label makers are designed to create adhesive labels for organizing, identifying, and categorizing office items, enhancing efficiency through clear visual tags. Barcode scanners function by reading encoded data on barcodes to quickly track inventory, streamline asset management, and improve checkout processes. Both devices serve distinct primary functions: label makers produce tangible identification tools, while barcode scanners facilitate digital data capture and processing.

Ease of Use and Setup Comparison

Label makers typically offer user-friendly interfaces with straightforward setup processes that include plug-and-play functionality and simple software integration, making them ideal for quick, on-the-spot labeling tasks. Barcode scanners often require more initial configuration, including pairing with inventory software and calibrating settings for various barcode types, which can be complex for beginners. In terms of ease of use, label makers excel in environments where rapid label creation is needed, whereas barcode scanners demand a short learning curve to achieve efficient operation in inventory management.

Efficiency in Office Organization

Label makers enhance office organization efficiency by providing clear, customizable labels that simplify item identification and inventory management. Barcode scanners streamline data entry and tracking processes, reducing errors and accelerating workflow in inventory control and asset management. Together, these tools optimize operational efficiency by minimizing manual tasks and improving data accuracy in office environments.

Cost Analysis: Label Makers vs Barcode Scanners

Label makers typically have lower upfront costs, ranging from $20 to $200 depending on features, while barcode scanners generally start at $50 and can exceed $500 for advanced models. Maintenance expenses for label makers are primarily limited to label tape refills, whereas barcode scanners may require more frequent calibration and replacement of scanning components. Businesses must consider total cost of ownership, including consumables and durability, to determine the most cost-effective option for their office supply needs.

Compatibility with Office Systems

Label makers often offer seamless integration with popular office software such as Microsoft Office and Google Workspace, enabling easy customization and printing of labels directly from spreadsheets or documents. Barcode scanners typically support compatibility with inventory management and point-of-sale (POS) systems, often connecting via USB, Bluetooth, or Wi-Fi to streamline data capture and tracking. Selecting devices with robust software compatibility ensures efficient workflow integration and reduces manual entry errors in office environments.

Choosing the Right Device for Your Office Needs

Selecting the right office device depends on your specific workflow requirements; label makers excel in creating customized labels for organizing files, shelves, and equipment, while barcode scanners streamline inventory management and product tracking. Consider the volume of items you handle daily and whether your priority is accurate item identification or efficient data entry. Integrating both devices can optimize labeling accuracy and inventory control, enhancing overall office productivity.

Conclusion: Which is Best for Your Office?

A label maker is best suited for offices needing customizable labels for organization and identification, enhancing efficiency with clear, personalized tags. Barcode scanners excel in environments requiring fast, accurate inventory tracking and point-of-sale operations, streamlining data capture and reducing errors. Choose a label maker for versatile labeling tasks and a barcode scanner for automated data management and inventory control.

Label Maker vs Barcode Scanner Infographic

productdif.com

productdif.com