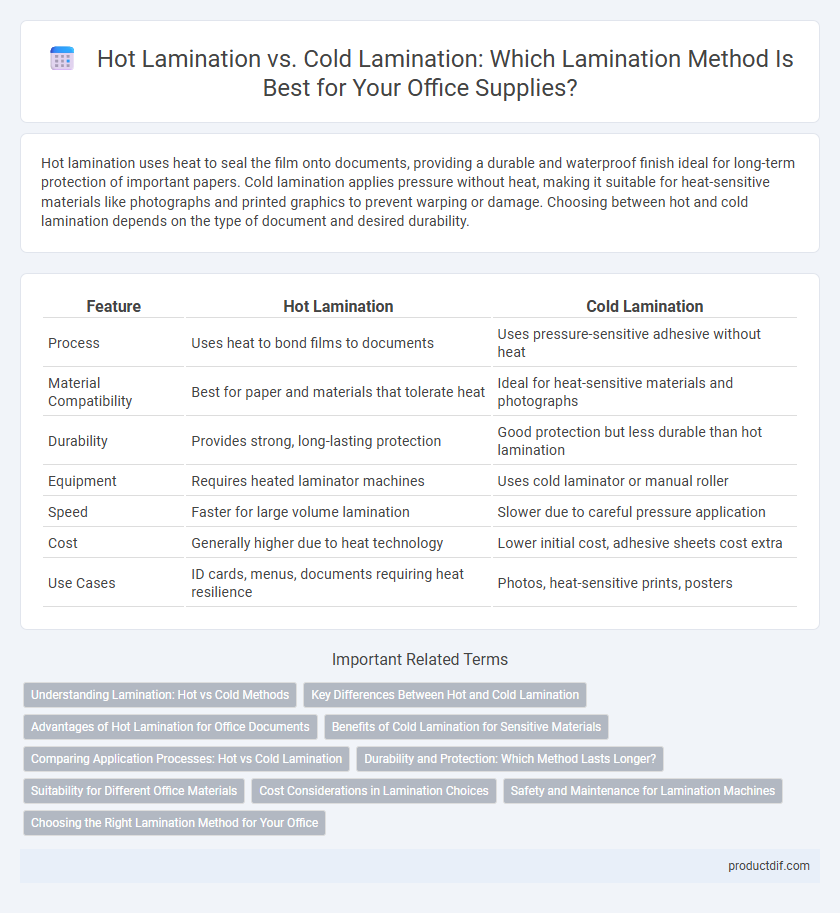

Hot lamination uses heat to seal the film onto documents, providing a durable and waterproof finish ideal for long-term protection of important papers. Cold lamination applies pressure without heat, making it suitable for heat-sensitive materials like photographs and printed graphics to prevent warping or damage. Choosing between hot and cold lamination depends on the type of document and desired durability.

Table of Comparison

| Feature | Hot Lamination | Cold Lamination |

|---|---|---|

| Process | Uses heat to bond films to documents | Uses pressure-sensitive adhesive without heat |

| Material Compatibility | Best for paper and materials that tolerate heat | Ideal for heat-sensitive materials and photographs |

| Durability | Provides strong, long-lasting protection | Good protection but less durable than hot lamination |

| Equipment | Requires heated laminator machines | Uses cold laminator or manual roller |

| Speed | Faster for large volume lamination | Slower due to careful pressure application |

| Cost | Generally higher due to heat technology | Lower initial cost, adhesive sheets cost extra |

| Use Cases | ID cards, menus, documents requiring heat resilience | Photos, heat-sensitive prints, posters |

Understanding Lamination: Hot vs Cold Methods

Hot lamination uses heat to activate the adhesive on the laminating film, creating a strong, durable seal that enhances document protection and longevity. Cold lamination relies on pressure-sensitive adhesives without heat, making it ideal for heat-sensitive materials like photos, magazines, or delicate papers. Selecting the appropriate lamination method depends on the type of document, required durability, and sensitivity to heat during office supply applications.

Key Differences Between Hot and Cold Lamination

Hot lamination uses heat and pressure to bond the film to the document, resulting in a durable, glossy finish ideal for frequently handled items. Cold lamination relies on pressure-sensitive adhesives and does not require heat, making it suitable for heat-sensitive materials like photographs and documents with thermal inks. Key differences include speed, finish quality, material compatibility, and application temperature.

Advantages of Hot Lamination for Office Documents

Hot lamination enhances office documents by providing superior durability and moisture resistance, ensuring long-lasting protection against wear and tear. It creates a strong seal that preserves the document's integrity, ideal for frequently handled materials like ID cards, menus, and certificates. This method also offers a professional, glossy finish that improves the visual appeal and readability of important office paperwork.

Benefits of Cold Lamination for Sensitive Materials

Cold lamination preserves the integrity of sensitive materials such as photographs, delicate documents, and heat-sensitive papers by avoiding exposure to high temperatures that can cause warping or discoloration. This method uses pressure-sensitive adhesives, ensuring a smooth finish without risk of thermal damage, making it ideal for fragile or heat-sensitive office supplies. Cold lamination also offers quick application and repositionable adhesive features, enhancing protection and longevity while maintaining the original quality of valuable documents.

Comparing Application Processes: Hot vs Cold Lamination

Hot lamination utilizes heat and pressure to melt adhesive films onto documents, providing a durable, glossy finish ideal for long-term protection of photos, ID cards, and certificates. Cold lamination applies pressure-sensitive adhesive without heat, making it suitable for heat-sensitive materials like photos, inkjet prints, and documents prone to smudging. The choice between hot and cold lamination depends on the material type and desired durability, with hot lamination offering stronger adhesion and cold lamination providing safer handling of delicate papers.

Durability and Protection: Which Method Lasts Longer?

Hot lamination uses heat to seal documents with a plastic film, offering superior durability and resistance to moisture, scratches, and wear compared to cold lamination. Cold lamination, which relies on pressure-sensitive adhesives, provides adequate protection for short-term use but tends to peel or bubble over time. For long-lasting preservation and maximum protection, hot lamination is the preferred office supply choice.

Suitability for Different Office Materials

Hot lamination is ideal for office materials like documents, posters, and ID cards that benefit from a durable, heat-activated seal providing enhanced protection and rigidity. Cold lamination suits heat-sensitive items such as photographs, delicate papers, and printed materials prone to damage from high temperatures, offering a protective layer without heat exposure. Selecting the appropriate lamination method depends on the material's heat tolerance and the desired level of durability and finish in office applications.

Cost Considerations in Lamination Choices

Hot lamination typically incurs higher upfront costs due to specialized equipment and heat-activated adhesives, making it a more significant initial investment for office supply budgets. Cold lamination offers cost efficiency through lower equipment prices and reduced energy consumption, ideal for projects with heat-sensitive materials and smaller volume needs. Evaluating long-term usage, maintenance expenses, and application-specific durability helps determine the most economical lamination option for office environments.

Safety and Maintenance for Lamination Machines

Hot lamination machines require careful handling due to high operating temperatures, posing burn risks and necessitating regular cleaning to prevent adhesive buildup on rollers, which can impair performance. Cold lamination machines operate at room temperature, reducing safety hazards and requiring less intensive maintenance, but the pressure rollers still need periodic cleaning to avoid residue accumulation. Proper ventilation and routine inspection of both types ensure machine longevity and safe office environments.

Choosing the Right Lamination Method for Your Office

Hot lamination uses heat to seal documents, providing a durable, moisture-resistant finish ideal for frequently handled office materials like ID cards and certificates. Cold lamination relies on pressure-sensitive adhesives, making it suitable for heat-sensitive documents such as photographs and printed photos prone to melting or warping. Selecting the right lamination method depends on the document type, desired durability, and sensitivity to temperature to ensure optimal preservation and presentation in the office environment.

Hot Lamination vs Cold Lamination Infographic

productdif.com

productdif.com