Polycarbonate offers superior impact resistance and durability compared to ABS plastic, making it ideal for protecting luggage pets during travel. ABS plastic is lighter and more affordable but tends to scratch and crack more easily under stress. Choosing polycarbonate ensures better long-term protection, while ABS suits budget-conscious travelers seeking lightweight options.

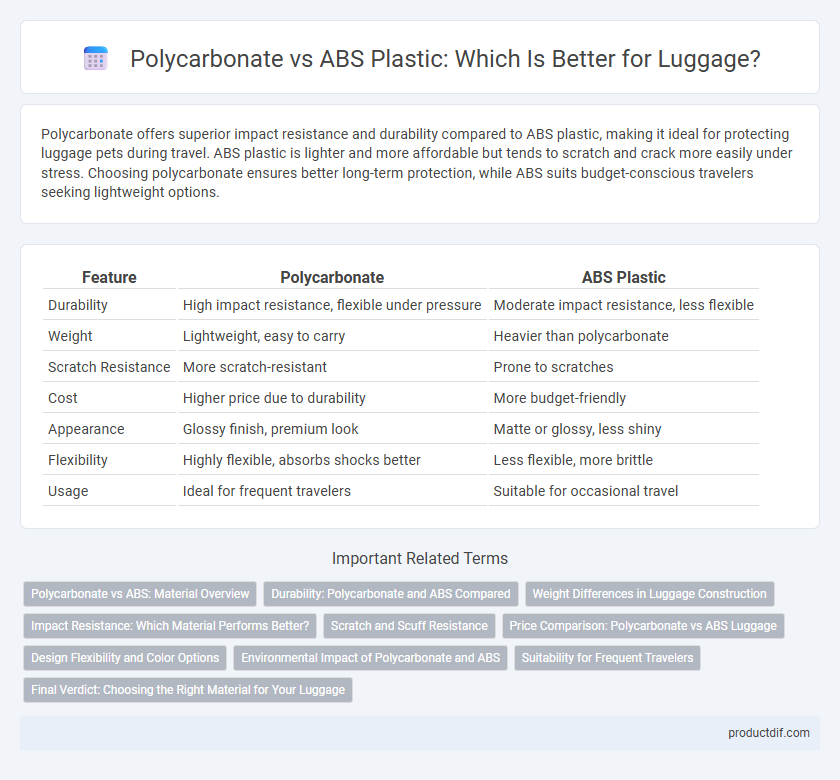

Table of Comparison

| Feature | Polycarbonate | ABS Plastic |

|---|---|---|

| Durability | High impact resistance, flexible under pressure | Moderate impact resistance, less flexible |

| Weight | Lightweight, easy to carry | Heavier than polycarbonate |

| Scratch Resistance | More scratch-resistant | Prone to scratches |

| Cost | Higher price due to durability | More budget-friendly |

| Appearance | Glossy finish, premium look | Matte or glossy, less shiny |

| Flexibility | Highly flexible, absorbs shocks better | Less flexible, more brittle |

| Usage | Ideal for frequent travelers | Suitable for occasional travel |

Polycarbonate vs ABS: Material Overview

Polycarbonate offers superior durability and impact resistance compared to ABS plastic, making it ideal for high-performance luggage. ABS is lighter and more cost-effective but less flexible under pressure, increasing the risk of cracking. Both materials provide water resistance, but polycarbonate's molecular structure ensures enhanced longevity and better protection for contents.

Durability: Polycarbonate and ABS Compared

Polycarbonate luggage offers superior durability due to its impact-resistant properties, providing better protection against dents and cracks compared to ABS plastic. ABS plastic, while more affordable and lightweight, tends to be less resilient under heavy stress and prolonged use. The choice between polycarbonate and ABS ultimately depends on balancing durability needs with budget considerations for luggage.

Weight Differences in Luggage Construction

Polycarbonate luggage is significantly lighter than ABS plastic, often reducing the overall weight by 20-30%, which enhances portability and ease of handling. The advanced molecular structure of polycarbonate provides superior strength-to-weight ratio, allowing for thinner yet more impact-resistant designs compared to ABS. Travelers benefit from lighter polycarbonate suitcases, especially during extended trips or strict airline weight limits.

Impact Resistance: Which Material Performs Better?

Polycarbonate luggage offers superior impact resistance due to its ability to flex and absorb shocks without cracking, making it ideal for travelers seeking durability. ABS plastic, while generally more affordable, tends to be more rigid and prone to cracking under heavy impact. Choosing polycarbonate luggage ensures enhanced protection for belongings during rough handling and frequent travel.

Scratch and Scuff Resistance

Polycarbonate luggage offers superior scratch and scuff resistance compared to ABS plastic, making it more durable for frequent travelers. Its molecular structure provides flexibility and toughness, reducing surface damage from impact and abrasion. ABS plastic, while lightweight and cost-effective, tends to show scratches and scuffs more easily due to its lower resistance properties.

Price Comparison: Polycarbonate vs ABS Luggage

Polycarbonate luggage typically commands a higher price due to its superior durability, impact resistance, and lightweight properties compared to ABS plastic. ABS luggage is more affordable, appealing to budget-conscious travelers, but may lack the same level of toughness and flexibility found in polycarbonate models. Price differences can vary by brand and design complexity, but polycarbonate suitcases often range from 20% to 40% more expensive than their ABS counterparts.

Design Flexibility and Color Options

Polycarbonate offers superior design flexibility compared to ABS plastic, allowing manufacturers to create more intricate and durable luggage shapes with enhanced impact resistance. Color options for polycarbonate luggage are typically richer and more vibrant due to its ability to hold pigments better during the molding process. ABS plastic, while more limited in design complexity and color vibrancy, provides a cost-effective choice for simpler luggage styles.

Environmental Impact of Polycarbonate and ABS

Polycarbonate luggage offers higher durability and longer lifespan compared to ABS plastic, reducing the frequency of replacement and waste generation. However, polycarbonate production involves more energy consumption and emits higher levels of greenhouse gases than ABS, which is generally easier to recycle but less robust. Choosing polycarbonate over ABS can lower environmental impact through extended product use, yet both materials present challenges in end-of-life disposal and recycling infrastructure.

Suitability for Frequent Travelers

Polycarbonate luggage offers superior impact resistance and durability, making it ideal for frequent travelers who need to withstand rough handling and frequent trips. ABS plastic suitcases are lighter and more affordable but may be less resistant to cracks and dents over time. Travelers prioritizing long-term protection and strength typically prefer polycarbonate for its ability to maintain structural integrity under pressure.

Final Verdict: Choosing the Right Material for Your Luggage

Polycarbonate offers superior durability, impact resistance, and flexibility, making it ideal for frequent travelers seeking long-lasting luggage. ABS plastic is lighter and more affordable, suited for occasional use or budget-conscious buyers. Evaluating your travel habits and budget will help determine whether the toughness of polycarbonate or the cost-effectiveness of ABS best fits your luggage needs.

Polycarbonate vs ABS plastic Infographic

productdif.com

productdif.com