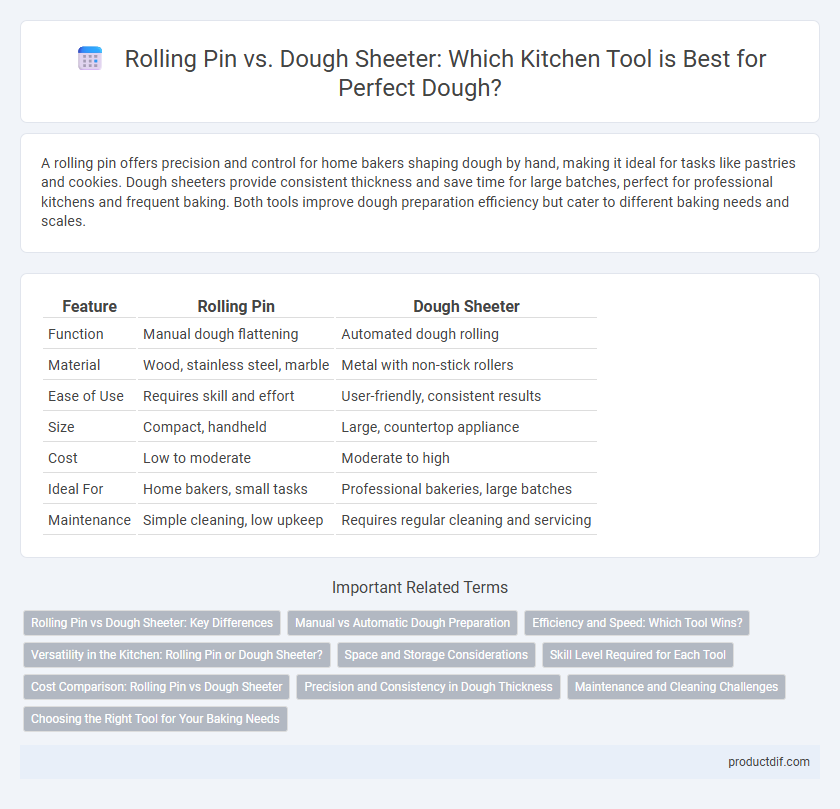

A rolling pin offers precision and control for home bakers shaping dough by hand, making it ideal for tasks like pastries and cookies. Dough sheeters provide consistent thickness and save time for large batches, perfect for professional kitchens and frequent baking. Both tools improve dough preparation efficiency but cater to different baking needs and scales.

Table of Comparison

| Feature | Rolling Pin | Dough Sheeter |

|---|---|---|

| Function | Manual dough flattening | Automated dough rolling |

| Material | Wood, stainless steel, marble | Metal with non-stick rollers |

| Ease of Use | Requires skill and effort | User-friendly, consistent results |

| Size | Compact, handheld | Large, countertop appliance |

| Cost | Low to moderate | Moderate to high |

| Ideal For | Home bakers, small tasks | Professional bakeries, large batches |

| Maintenance | Simple cleaning, low upkeep | Requires regular cleaning and servicing |

Rolling Pin vs Dough Sheeter: Key Differences

A rolling pin is a handheld kitchen tool used for manually flattening dough with precise control, ideal for small to medium batches and various textures. In contrast, a dough sheeter is an electric machine designed for quickly producing uniformly thin dough layers, making it suitable for large-scale baking and consistent thickness. Key differences include automation level, speed, dough uniformity, and suitability for home versus commercial use.

Manual vs Automatic Dough Preparation

Manual rolling pins offer tactile control over dough thickness and texture, ideal for artisanal baking and small batch preparations. Dough sheeters automate the process, providing consistent and uniform dough sheets with minimal physical effort, suitable for commercial kitchens. Choosing between them depends on volume demands and desired precision in dough preparation.

Efficiency and Speed: Which Tool Wins?

A dough sheeter outperforms a rolling pin in efficiency and speed by evenly flattening large batches of dough within seconds, streamlining bakery workflows significantly. While rolling pins require manual effort and time to achieve uniform thickness, dough sheeters provide precise, consistent results quickly, reducing labor-intensive tasks. For commercial kitchens, investing in a dough sheeter maximizes productivity and maintains dough quality, making it the preferred tool over rolling pins for high-volume dough preparation.

Versatility in the Kitchen: Rolling Pin or Dough Sheeter?

A rolling pin offers versatile control for shaping dough of various sizes and thicknesses, making it ideal for tasks like pie crusts, cookies, and pastries. A dough sheeter provides consistent, even thickness for large batches, enhancing efficiency in commercial kitchens or extensive baking projects. The choice depends on whether precision and speed or hands-on customization is prioritized in kitchen workflows.

Space and Storage Considerations

Rolling pins are compact and easy to store in most kitchen drawers or on hanging racks, making them ideal for small kitchens with limited space. Dough sheeters require more countertop or storage space due to their larger size and mechanical components, often unsuitable for compact kitchens. Choosing a rolling pin optimizes space utilization while a dough sheeter demands dedicated storage and setup areas.

Skill Level Required for Each Tool

A rolling pin requires minimal skill, making it ideal for beginners learning to roll dough evenly by hand. A dough sheeter demands intermediate to advanced skills for precise control of dough thickness and uniformity, often used in professional baking settings. Mastery of a dough sheeter enhances efficiency and consistency, whereas a rolling pin offers greater tactile feedback and manual precision.

Cost Comparison: Rolling Pin vs Dough Sheeter

A rolling pin is an affordable kitchen tool typically priced between $10 and $50, making it accessible for home bakers and small-scale use. Dough sheeters, by contrast, are industrial-grade machines costing from $1,000 to over $10,000, designed for high-volume commercial kitchens requiring consistent dough thickness. The significant price difference highlights the rolling pin as the cost-efficient choice for casual baking, while dough sheeters justify their expense through time-saving automation in professional settings.

Precision and Consistency in Dough Thickness

A dough sheeter delivers unmatched precision and consistency in dough thickness by using adjustable rollers to ensure uniform sheets ideal for commercial baking. Rolling pins rely heavily on user skill, often resulting in uneven dough thickness, which can affect baking quality. For tasks demanding exact thickness and repeatability, dough sheeters provide superior control and efficiency.

Maintenance and Cleaning Challenges

Maintaining a rolling pin requires simple cleaning with warm soap and water, often followed by thorough drying to prevent wood warping or metal rusting. Dough sheeters pose more complex cleaning challenges due to multiple moving parts and electrical components, necessitating regular disassembly and specialized cleaning to avoid damage and maintain hygiene standards. Proper maintenance of both tools extends their lifespan and ensures consistent performance in dough preparation.

Choosing the Right Tool for Your Baking Needs

Choosing the right tool between a rolling pin and a dough sheeter depends on the volume and precision required in your baking process. Rolling pins offer manual control ideal for small batches and personalized dough thickness, while dough sheeters deliver consistent, uniform sheets for high-volume baking and professional-quality results. Bakers seeking efficiency and time-saving solutions often prefer dough sheeters, whereas home bakers value the versatility and tactile feedback of rolling pins.

Rolling Pin vs Dough Sheeter Infographic

productdif.com

productdif.com