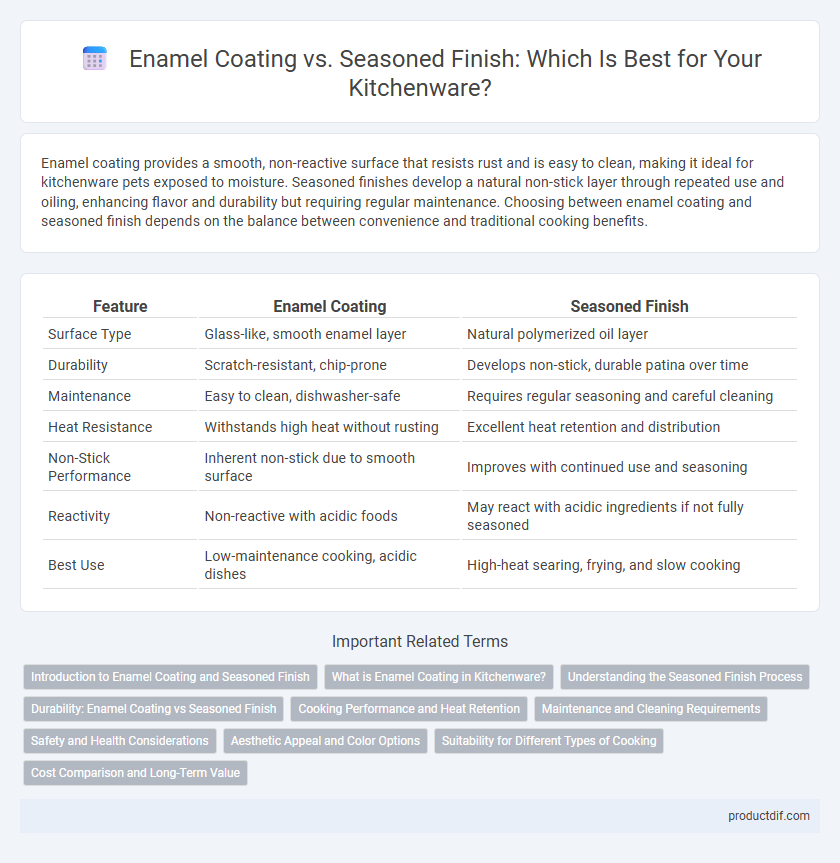

Enamel coating provides a smooth, non-reactive surface that resists rust and is easy to clean, making it ideal for kitchenware pets exposed to moisture. Seasoned finishes develop a natural non-stick layer through repeated use and oiling, enhancing flavor and durability but requiring regular maintenance. Choosing between enamel coating and seasoned finish depends on the balance between convenience and traditional cooking benefits.

Table of Comparison

| Feature | Enamel Coating | Seasoned Finish |

|---|---|---|

| Surface Type | Glass-like, smooth enamel layer | Natural polymerized oil layer |

| Durability | Scratch-resistant, chip-prone | Develops non-stick, durable patina over time |

| Maintenance | Easy to clean, dishwasher-safe | Requires regular seasoning and careful cleaning |

| Heat Resistance | Withstands high heat without rusting | Excellent heat retention and distribution |

| Non-Stick Performance | Inherent non-stick due to smooth surface | Improves with continued use and seasoning |

| Reactivity | Non-reactive with acidic foods | May react with acidic ingredients if not fully seasoned |

| Best Use | Low-maintenance cooking, acidic dishes | High-heat searing, frying, and slow cooking |

Introduction to Enamel Coating and Seasoned Finish

Enamel coating offers a durable, non-reactive surface that resists rust and provides easy cleanup, making it ideal for cookware like cast iron pans and Dutch ovens. Seasoned finish, created by polymerizing oils onto cast iron, forms a natural non-stick layer that enhances flavor and improves with use over time. Both finishes protect cookware while catering to different cooking preferences and maintenance routines.

What is Enamel Coating in Kitchenware?

Enamel coating in kitchenware is a durable, non-porous layer of fused glass applied to metal cookware, typically cast iron or steel, providing a smooth, rust-resistant surface. This coating prevents food from sticking, enhances easy cleaning, and eliminates the need for seasoning unlike traditional seasoned finishes. Enamel-coated cookware offers vibrant colors and resists acidic foods, making it ideal for diverse cooking methods and long-lasting kitchen use.

Understanding the Seasoned Finish Process

The seasoned finish process involves baking oil into the surface of cookware, creating a natural, non-stick layer that improves with use and enhances heat retention. Unlike enamel coating, which is a vitreous layer fused to metal at high temperatures, seasoning polymerizes oils to bond with the cast iron or steel surface. This method requires regular maintenance such as oil application and heating to maintain its protective and non-stick properties, making it ideal for cast iron skillets and similar kitchenware.

Durability: Enamel Coating vs Seasoned Finish

Enamel coating offers superior durability by providing a hard, non-porous surface resistant to rust, stains, and scratching, making it ideal for long-term use and easy maintenance. Seasoned finishes develop a natural non-stick patina through polymerized oils, enhancing durability over time but requiring regular upkeep to prevent rust and damage. While enamel coatings maintain consistent protection without reapplication, seasoned finishes grow stronger yet demand careful handling to preserve their durability.

Cooking Performance and Heat Retention

Enamel coating provides a smooth, non-reactive surface that ensures even cooking and easy cleaning while maintaining consistent heat distribution. Seasoned finishes create a natural, non-stick layer that improves with use and offers superior heat retention, enhancing flavor development. Both finishes affect cooking performance by balancing heat conduction and durability, but enamel excels in low-maintenance use while seasoned surfaces favor high-heat cooking techniques.

Maintenance and Cleaning Requirements

Enamel coating offers a non-porous surface that resists rust and requires simple cleaning with mild soap and water, avoiding abrasive materials to maintain its glossy finish. Seasoned finishes build a natural non-stick layer through regular oiling and heating, necessitating careful maintenance by drying promptly and occasional reseasoning to prevent rust and preserve cooking quality. Proper cleaning of enamel-coated cookware involves avoiding metal utensils, while seasoned cookware benefits from gentle scrubbing without detergent to retain its protective patina.

Safety and Health Considerations

Enamel coating provides a non-reactive, BPA-free surface that prevents food from interacting with metal, minimizing the risk of harmful chemical leaching and ensuring safe cooking for all types of food. Seasoned finishes develop a natural non-stick layer composed of polymerized fats, which, while generally safe, require careful maintenance to avoid bacterial buildup and rust. Choosing enamel-coated cookware supports easy cleaning and durability without compromising the health benefits associated with non-toxic, inert kitchenware surfaces.

Aesthetic Appeal and Color Options

Enamel coating offers a vibrant, glossy aesthetic with a wide range of color options, enhancing kitchenware's visual appeal and making it a popular choice for decorative cookware. Seasoned finishes provide a natural, matte, and rustic look that develops a unique patina over time, appealing to those who favor traditional and understated styles. Both finishes influence the overall kitchen decor, but enamel coating stands out for bold, consistent colors while seasoned finishes emphasize authentic, evolving textures.

Suitability for Different Types of Cooking

Enamel coating provides a non-reactive, easy-to-clean surface ideal for acidic dishes like tomato sauces, making it suitable for simmering and slow cooking without flavor alteration. Seasoned finish, typically found on cast iron, offers superior heat retention and natural non-stick properties, perfect for high-heat searing, frying, and baking. Choosing between enamel and seasoned cookware depends on cooking style, as enamel excels in gentle heat applications while seasoned finishes thrive in high-temperature culinary techniques.

Cost Comparison and Long-Term Value

Enamel coating typically involves higher upfront costs due to specialized materials and manufacturing processes but offers superior resistance to rust and requires minimal maintenance, enhancing long-term durability. Seasoned finishes, common in cast iron cookware, demand ongoing upkeep such as regular oiling and seasoning to maintain non-stick properties and prevent rust, which can increase lifetime maintenance costs despite a lower initial price. Over time, enamel-coated kitchenware tends to provide better value by reducing the need for replacement and maintenance, while seasoned finishes offer cost savings upfront but may incur higher long-term expenses.

Enamel Coating vs Seasoned Finish Infographic

productdif.com

productdif.com