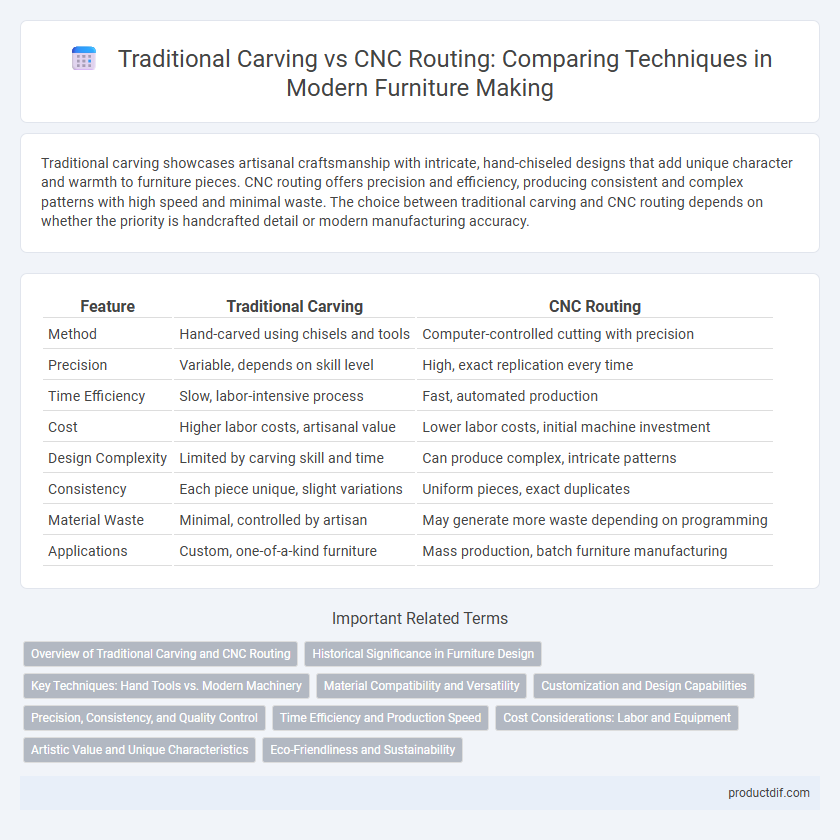

Traditional carving showcases artisanal craftsmanship with intricate, hand-chiseled designs that add unique character and warmth to furniture pieces. CNC routing offers precision and efficiency, producing consistent and complex patterns with high speed and minimal waste. The choice between traditional carving and CNC routing depends on whether the priority is handcrafted detail or modern manufacturing accuracy.

Table of Comparison

| Feature | Traditional Carving | CNC Routing |

|---|---|---|

| Method | Hand-carved using chisels and tools | Computer-controlled cutting with precision |

| Precision | Variable, depends on skill level | High, exact replication every time |

| Time Efficiency | Slow, labor-intensive process | Fast, automated production |

| Cost | Higher labor costs, artisanal value | Lower labor costs, initial machine investment |

| Design Complexity | Limited by carving skill and time | Can produce complex, intricate patterns |

| Consistency | Each piece unique, slight variations | Uniform pieces, exact duplicates |

| Material Waste | Minimal, controlled by artisan | May generate more waste depending on programming |

| Applications | Custom, one-of-a-kind furniture | Mass production, batch furniture manufacturing |

Overview of Traditional Carving and CNC Routing

Traditional carving in furniture involves skilled artisans shaping wood by hand using chisels and gouges, emphasizing intricate, unique designs that reflect craftsmanship and historical techniques. CNC routing employs computer-controlled machinery to precisely cut and shape wood, enabling high-speed production with consistent accuracy and reproducibility of complex patterns. Both methods offer distinct advantages in texture and detail, with traditional carving highlighting artistic individuality and CNC routing excelling in efficiency and uniformity for large-scale manufacturing.

Historical Significance in Furniture Design

Traditional carving in furniture design embodies centuries of craftsmanship, showcasing intricate handwork that reflects cultural heritage and artisan skill passed down through generations. CNC routing introduces precision and efficiency, transforming historical patterns into consistent, scalable designs while maintaining stylistic elements rooted in classical woodworking traditions. The evolution from hand-carved to CNC-routed furniture highlights a fusion of historical artistry and modern technology in preserving design legacies.

Key Techniques: Hand Tools vs. Modern Machinery

Traditional carving relies on hand tools such as chisels, gouges, and mallets to create intricate, artisanal designs that highlight the wood's natural character and require skilled craftsmanship. CNC routing utilizes computer-controlled machinery to precisely cut and shape wood, offering consistent replication of complex patterns with high efficiency and minimal manual labor. Both techniques serve different purposes in furniture making, with hand carving emphasizing uniqueness and artistry while CNC routing excels in mass production and precision.

Material Compatibility and Versatility

Traditional carving excels in working with hardwoods like mahogany and oak, offering unmatched detail and texture ideal for custom, artisanal furniture. CNC routing supports a wider range of materials including softwoods, plastics, and composites, enabling consistent precision and versatility across diverse design applications. Select CNC routing for scalable production and complex patterns, while traditional carving suits projects demanding handcrafted authenticity.

Customization and Design Capabilities

Traditional carving offers intricate, handcrafted details that reflect artisanal skill and heritage, allowing unique and complex designs tailored to individual preferences. CNC routing provides precise and consistent customization through automated control, enabling complex, repetitive patterns with high accuracy and faster production times. Both methods enhance design capabilities, but CNC routing excels in scalability and digital precision, while traditional carving emphasizes craftsmanship and originality.

Precision, Consistency, and Quality Control

Traditional carving offers unique craftsmanship with subtle variations that highlight artisanal skill, but it lacks the precise repeatability achievable with CNC routing. CNC routing delivers exceptional precision and consistency by using computer-controlled tools, ensuring uniform quality across large production runs. Quality control in CNC routing benefits from automated processes that reduce human error, while traditional carving relies on manual inspection to maintain standards.

Time Efficiency and Production Speed

Traditional carving requires skilled artisans and can take several hours or days per piece, limiting production speed and overall time efficiency. CNC routing automates the carving process, enabling high precision and faster turnaround times, often completing intricate designs in minutes. This shift significantly increases production capacity while maintaining consistent quality in furniture manufacturing.

Cost Considerations: Labor and Equipment

Traditional carving demands high labor costs due to skilled artisans requiring extensive time to complete intricate designs, increasing overall project expenses. CNC routing minimizes labor costs by automating precision cuts, though it involves significant initial investment in sophisticated machinery and software. Balancing long-term production efficiency with upfront equipment expenses is crucial in selecting between traditional carving and CNC routing for furniture manufacturing.

Artistic Value and Unique Characteristics

Traditional carving in furniture showcases the artisan's skill through intricate, hand-crafted details that convey cultural heritage and unique imperfections, creating one-of-a-kind pieces. CNC routing offers precision and repeatability, enabling complex patterns with consistency but often lacks the nuanced depth that characterizes handcrafted artistry. The artistic value of traditional carving lies in its individuality and tactile texture, whereas CNC routing emphasizes efficiency and uniformity in design execution.

Eco-Friendliness and Sustainability

Traditional carving uses hand tools and natural materials, resulting in minimal energy consumption and reduced environmental impact compared to CNC routing, which relies on electricity and produces metal and plastic waste. The slow, manual process of traditional carving promotes sustainable craftsmanship by preserving cultural techniques and supporting local artisans. CNC routing, however, offers precision and efficiency but often depends on non-renewable resources and generates higher carbon emissions.

Traditional carving vs CNC routing Infographic

productdif.com

productdif.com