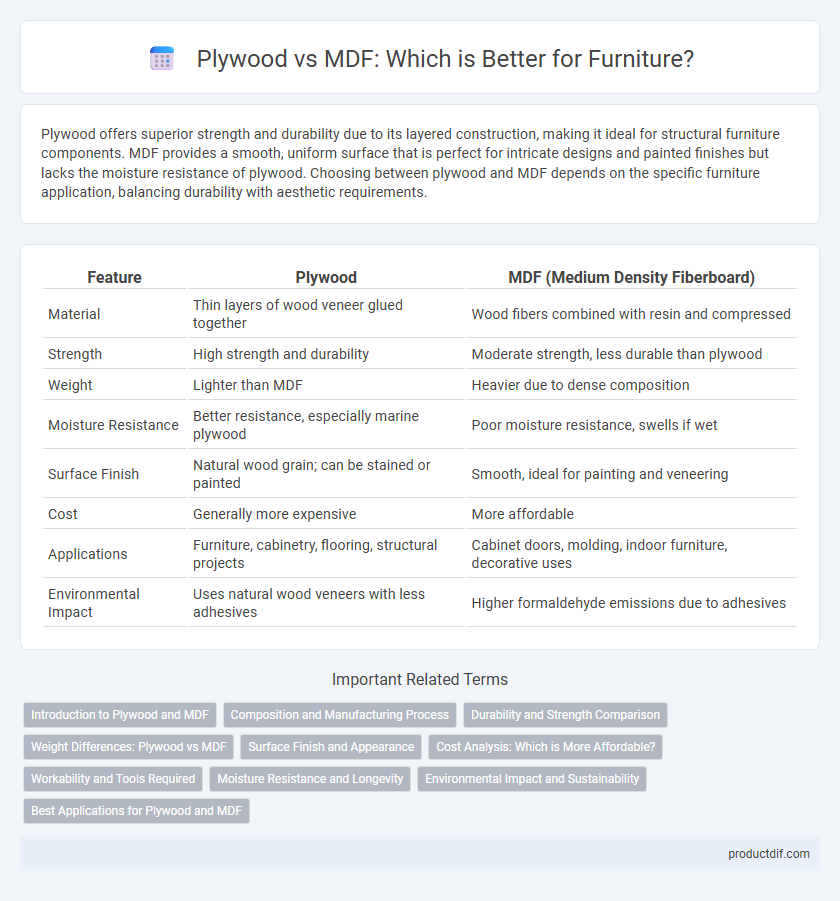

Plywood offers superior strength and durability due to its layered construction, making it ideal for structural furniture components. MDF provides a smooth, uniform surface that is perfect for intricate designs and painted finishes but lacks the moisture resistance of plywood. Choosing between plywood and MDF depends on the specific furniture application, balancing durability with aesthetic requirements.

Table of Comparison

| Feature | Plywood | MDF (Medium Density Fiberboard) |

|---|---|---|

| Material | Thin layers of wood veneer glued together | Wood fibers combined with resin and compressed |

| Strength | High strength and durability | Moderate strength, less durable than plywood |

| Weight | Lighter than MDF | Heavier due to dense composition |

| Moisture Resistance | Better resistance, especially marine plywood | Poor moisture resistance, swells if wet |

| Surface Finish | Natural wood grain; can be stained or painted | Smooth, ideal for painting and veneering |

| Cost | Generally more expensive | More affordable |

| Applications | Furniture, cabinetry, flooring, structural projects | Cabinet doors, molding, indoor furniture, decorative uses |

| Environmental Impact | Uses natural wood veneers with less adhesives | Higher formaldehyde emissions due to adhesives |

Introduction to Plywood and MDF

Plywood consists of multiple thin layers of wood veneer glued together, providing excellent strength and durability for furniture construction. MDF (Medium-Density Fiberboard) is made from wood fibers bonded with resin under heat and pressure, offering a smooth, uniform surface ideal for painting and detailed woodworking. Both materials are widely used in furniture making, with plywood favored for structural integrity and MDF for its affordability and finish quality.

Composition and Manufacturing Process

Plywood consists of multiple layers of thin wood veneers glued together with alternating grain directions, enhancing its strength and resistance to warping. MDF (Medium-Density Fiberboard) is made from wood fibers, wax, and resin compressed under high temperature and pressure, resulting in a smooth, uniform surface. The manufacturing of plywood involves peeling logs into sheets and bonding them, whereas MDF production requires breaking down wood into fibers before reconstituting into panels.

Durability and Strength Comparison

Plywood features cross-laminated wood veneers providing high strength and resistance to warping, making it ideal for load-bearing furniture applications. MDF, composed of fine wood fibers and resin, offers a smooth surface but is generally less durable and prone to sagging under heavy weight. For long-lasting furniture requiring structural integrity, plywood outperforms MDF in durability and strength.

Weight Differences: Plywood vs MDF

Plywood is generally lighter than MDF due to its layered wood veneer construction, which combines strength with reduced density. MDF is denser and heavier because it is made from fine wood fibers bonded with resin under high pressure. The weight difference affects handling, transportation, and suitability for certain furniture applications, with plywood preferred where weight reduction is crucial.

Surface Finish and Appearance

Plywood features a natural wood veneer surface that offers a rich, authentic grain and texture, making it ideal for furniture where aesthetics are key. MDF provides a smooth, uniform surface that is perfect for painting or laminating, resulting in a sleek, consistent finish without visible wood grain. While plywood's surface varies with wood species, MDF's dense composition ensures superior smoothness and paint adhesion for modern, minimalist designs.

Cost Analysis: Which is More Affordable?

Plywood typically costs more than MDF due to its layered construction using natural wood veneers, offering superior strength and durability. MDF is more affordable, made from fine wood fibers bonded with resin, making it a budget-friendly option for furniture projects that don't require load-bearing strength. When considering long-term value, plywood's resistance to warping and moisture can justify its higher initial price compared to MDF's susceptibility to damage and shorter lifespan.

Workability and Tools Required

Plywood offers superior workability for furniture making due to its layered construction, allowing easy cutting, sanding, and fastening with standard woodworking tools such as saws, drills, and routers. MDF, known for its smooth surface, requires sharp carbide-tipped blades and fine-toothed saws to prevent chipping and dust production, making specialized dust extraction systems essential for safe handling. Choosing between plywood and MDF depends on the precision of cuts, edge finishing, and the type of tools available to achieve the desired furniture design.

Moisture Resistance and Longevity

Plywood offers superior moisture resistance compared to MDF due to its layered construction with adhesive bonding, making it less prone to swelling and warping in humid environments. MDF, composed of fine wood fibers and resin, tends to absorb moisture more readily, leading to reduced durability in wet conditions. For furniture exposed to moisture or requiring long-term structural integrity, plywood is a more reliable choice, enhancing longevity and maintaining form over time.

Environmental Impact and Sustainability

Plywood offers better environmental sustainability due to its use of thin wood veneers that maximize natural wood resources and minimize waste, often sourced from fast-growing trees. MDF, made from wood fibers and resin, involves higher energy consumption and emits formaldehyde, raising concerns about air quality and environmental health. Choosing plywood over MDF supports reduced ecological footprints and promotes more sustainable furniture production practices.

Best Applications for Plywood and MDF

Plywood is best suited for applications requiring strength and durability, such as cabinetry, flooring, and load-bearing furniture, due to its layered construction and resistance to warping. MDF excels in furniture projects needing smooth surfaces and intricate detailing, like decorative panels and painted furniture, owing to its uniform density and fine texture. Choosing between plywood and MDF depends on the balance between structural support and finish quality desired for the furniture piece.

Plywood vs MDF Infographic

productdif.com

productdif.com