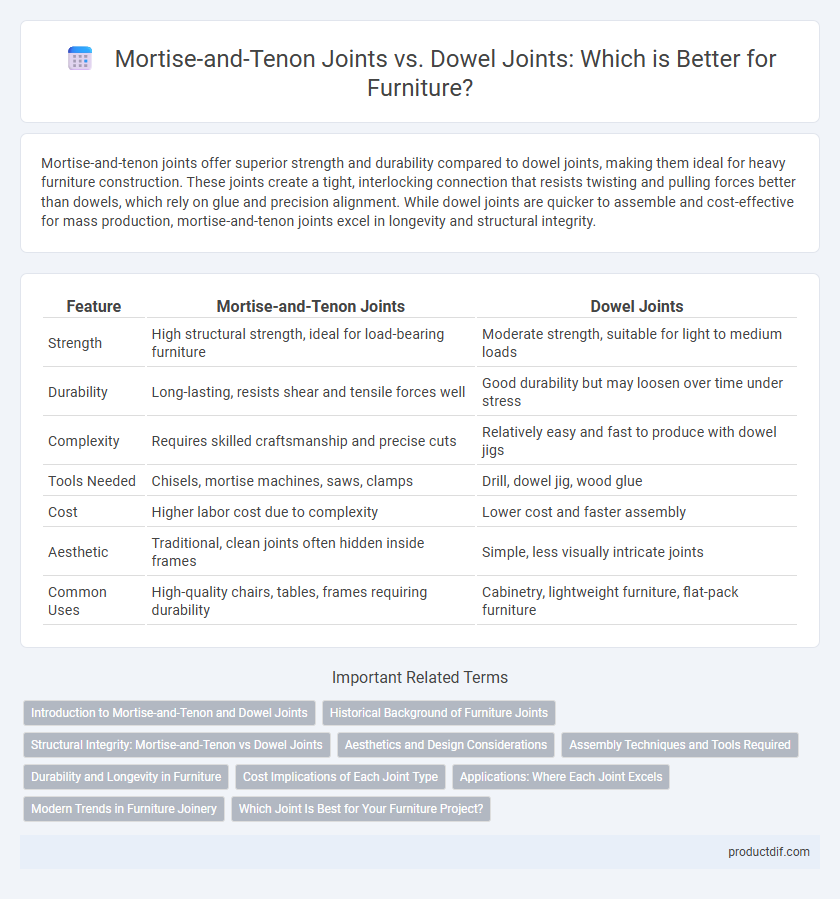

Mortise-and-tenon joints offer superior strength and durability compared to dowel joints, making them ideal for heavy furniture construction. These joints create a tight, interlocking connection that resists twisting and pulling forces better than dowels, which rely on glue and precision alignment. While dowel joints are quicker to assemble and cost-effective for mass production, mortise-and-tenon joints excel in longevity and structural integrity.

Table of Comparison

| Feature | Mortise-and-Tenon Joints | Dowel Joints |

|---|---|---|

| Strength | High structural strength, ideal for load-bearing furniture | Moderate strength, suitable for light to medium loads |

| Durability | Long-lasting, resists shear and tensile forces well | Good durability but may loosen over time under stress |

| Complexity | Requires skilled craftsmanship and precise cuts | Relatively easy and fast to produce with dowel jigs |

| Tools Needed | Chisels, mortise machines, saws, clamps | Drill, dowel jig, wood glue |

| Cost | Higher labor cost due to complexity | Lower cost and faster assembly |

| Aesthetic | Traditional, clean joints often hidden inside frames | Simple, less visually intricate joints |

| Common Uses | High-quality chairs, tables, frames requiring durability | Cabinetry, lightweight furniture, flat-pack furniture |

Introduction to Mortise-and-Tenon and Dowel Joints

Mortise-and-tenon joints consist of a rectangular peg (tenon) that fits tightly into a corresponding cavity (mortise), providing strong, durable connections ideal for load-bearing furniture frameworks. Dowel joints use cylindrical wooden pins inserted into aligned holes in adjoining pieces, offering simpler assembly but generally less strength compared to mortise-and-tenon joints. Both techniques are fundamental in traditional woodworking, with mortise-and-tenon favored for high-stress joints and dowel joints popular in mass-produced furniture due to ease of mechanization.

Historical Background of Furniture Joints

Mortise-and-tenon joints have been a cornerstone of furniture construction for over 7,000 years, evident in ancient Egyptian tombs and classical Greek woodworking, showcasing their enduring strength and reliability. Dowel joints, emerging prominently during the Industrial Revolution, revolutionized mass production by offering a simpler, faster method relying on cylindrical wooden pins to align and secure components. The evolution from handcrafted mortise-and-tenon to machine-made dowel joints reflects the transition from artisan craftsmanship to industrial manufacturing in furniture history.

Structural Integrity: Mortise-and-Tenon vs Dowel Joints

Mortise-and-tenon joints offer superior structural integrity due to their interlocking design, which provides greater resistance to shear and tension forces compared to dowel joints. The tenon fits snugly into the mortise, creating a strong mechanical bond that efficiently distributes stress across the joint. In contrast, dowel joints rely primarily on adhesive strength, making them less durable under heavy loads or long-term use in furniture construction.

Aesthetics and Design Considerations

Mortise-and-tenon joints offer a clean, seamless appearance ideal for traditional and high-end furniture designs, enhancing structural integrity without visible fasteners. Dowel joints can create subtle surface imperfections due to pin visibility, making them less suited for exquisite cabinetry or fine furniture where flawless aesthetics are crucial. Choosing between these joinery methods depends on the desired balance of design finesse, visual appeal, and the level of craftsmanship demanded by the furniture piece.

Assembly Techniques and Tools Required

Mortise-and-tenon joints require precise chiseling and mortising tools, such as mortise chisels, tenon saws, and marking gauges, to create interlocking parts that provide superior strength and durability. Dowel joints use dowel pins aligned with pre-drilled holes, assembled with dowel centers or jigs to ensure accurate placement, making them faster and easier for less complex constructions. The choice between these techniques depends on the desired joint strength and the availability of specialized tools for clean, tight-fitting connections.

Durability and Longevity in Furniture

Mortise-and-tenon joints provide superior durability and longevity in furniture due to their deep, interlocking fit that withstands heavy loads and stress over time. Dowel joints, while easier to assemble, tend to be less robust and may loosen with prolonged use or exposure to environmental changes. Solid hardwood construction combined with mortise-and-tenon joinery ensures optimal structural integrity and extended lifespan in high-quality furniture pieces.

Cost Implications of Each Joint Type

Mortise-and-tenon joints typically require more labor and skill, resulting in higher production costs compared to dowel joints, which are quicker and easier to assemble using simple jig tools. The expense of specialized equipment and the time-intensive nature of cutting precise mortises and tenons increase the overall cost for mortise-and-tenon furniture. Conversely, dowel joints offer a cost-effective alternative for mass production, as dowels can be rapidly inserted and glued with minimal training and no complex machinery.

Applications: Where Each Joint Excels

Mortise-and-tenon joints excel in heavy-duty furniture applications like bed frames and dining tables due to their superior strength and durability under stress. Dowel joints are ideal for lightweight furniture such as cabinets and chairs, offering quicker assembly and sufficient stability for less load-bearing parts. Choosing the right joint depends on the required structural integrity and the specific furniture design demands.

Modern Trends in Furniture Joinery

Modern trends in furniture joinery emphasize the balance between traditional craftsmanship and efficient manufacturing, with mortise-and-tenon joints offering unparalleled strength and longevity for solid wood furniture. Dowel joints continue to gain popularity for their ease of assembly and cost-effectiveness, especially in mass-produced and flat-pack furniture designs. Advances in CNC machining have enhanced the precision of both joint types, allowing designers to create seamless, durable connections that cater to contemporary minimalist aesthetics.

Which Joint Is Best for Your Furniture Project?

Mortise-and-tenon joints offer superior strength and durability, making them ideal for load-bearing furniture such as tables and chairs, while dowel joints simplify alignment and assembly, suitable for lightweight or flat-pack furniture. Choosing between these joints depends on factors like project complexity, required structural integrity, and available tools. For heirloom-quality or high-stress pieces, mortise-and-tenon provides unmatched stability, whereas dowel joints are efficient for quicker construction and mass production.

Mortise-and-tenon joints vs dowel joints Infographic

productdif.com

productdif.com