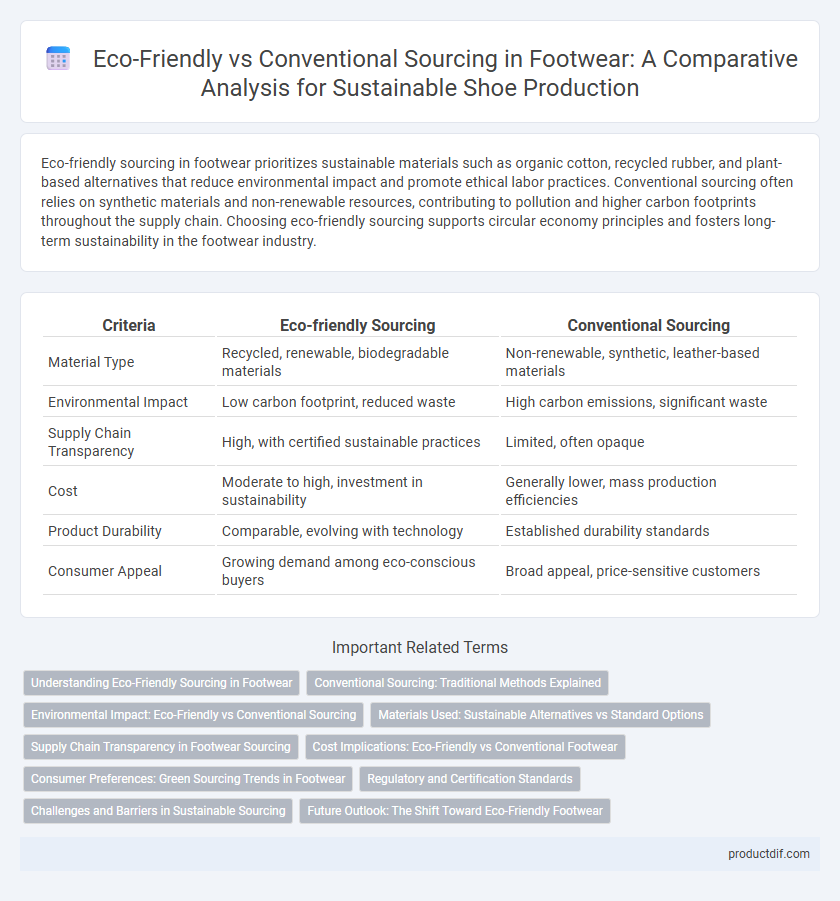

Eco-friendly sourcing in footwear prioritizes sustainable materials such as organic cotton, recycled rubber, and plant-based alternatives that reduce environmental impact and promote ethical labor practices. Conventional sourcing often relies on synthetic materials and non-renewable resources, contributing to pollution and higher carbon footprints throughout the supply chain. Choosing eco-friendly sourcing supports circular economy principles and fosters long-term sustainability in the footwear industry.

Table of Comparison

| Criteria | Eco-friendly Sourcing | Conventional Sourcing |

|---|---|---|

| Material Type | Recycled, renewable, biodegradable materials | Non-renewable, synthetic, leather-based materials |

| Environmental Impact | Low carbon footprint, reduced waste | High carbon emissions, significant waste |

| Supply Chain Transparency | High, with certified sustainable practices | Limited, often opaque |

| Cost | Moderate to high, investment in sustainability | Generally lower, mass production efficiencies |

| Product Durability | Comparable, evolving with technology | Established durability standards |

| Consumer Appeal | Growing demand among eco-conscious buyers | Broad appeal, price-sensitive customers |

Understanding Eco-Friendly Sourcing in Footwear

Eco-friendly sourcing in footwear emphasizes using sustainable materials such as organic cotton, recycled rubber, and plant-based leathers to reduce environmental impact. This approach prioritizes responsible supply chains, ensuring lower carbon footprints, reduced water consumption, and minimal chemical use compared to conventional sourcing. Brands adopting eco-friendly sourcing often integrate transparency and ethical labor practices to align with consumer demand for sustainability.

Conventional Sourcing: Traditional Methods Explained

Conventional sourcing in footwear relies heavily on mass-produced synthetic materials such as PVC and polyurethane, which contribute to environmental pollution and resource depletion. Traditional supply chains prioritize cost efficiency and scalability, often neglecting the ecological impact of leather tanning, chemical treatments, and waste generation. This method typically involves extensive use of fossil fuels and non-renewable resources, resulting in a larger carbon footprint compared to eco-friendly alternatives.

Environmental Impact: Eco-Friendly vs Conventional Sourcing

Eco-friendly sourcing in footwear prioritizes renewable materials and sustainable production methods, significantly reducing carbon footprints and minimizing water and chemical usage compared to conventional sourcing. Conventional sourcing often relies on synthetic materials and energy-intensive processes, contributing to higher greenhouse gas emissions and environmental degradation. Adopting eco-friendly alternatives supports biodiversity preservation and lowers overall pollution levels in the footwear industry.

Materials Used: Sustainable Alternatives vs Standard Options

Eco-friendly sourcing in footwear prioritizes materials such as organic cotton, recycled polyester, and natural rubber, reducing environmental impact through renewable and biodegradable components. Conventional sourcing relies heavily on synthetic fibers, petroleum-based plastics, and non-renewable resources, contributing to pollution and waste. Sustainable alternatives contribute to lower carbon footprints, enhanced durability, and improved recyclability compared to standard options used in traditional manufacturing processes.

Supply Chain Transparency in Footwear Sourcing

Eco-friendly sourcing in footwear emphasizes supply chain transparency by tracing materials from sustainable farms to manufacturing plants, reducing environmental footprint and promoting ethical labor practices. Conventional sourcing often lacks this visibility, leading to challenges in verifying the origin of synthetic materials and labor conditions. Enhanced transparency helps brands meet consumer demands for responsibly produced shoes and supports regulatory compliance across global markets.

Cost Implications: Eco-Friendly vs Conventional Footwear

Eco-friendly sourcing for footwear often incurs higher initial costs due to sustainable materials like organic cotton, recycled rubber, and biodegradable components, which require specialized manufacturing processes. Conventional sourcing typically benefits from economies of scale and lower raw material expenses, resulting in reduced production costs and more competitive retail pricing. However, eco-friendly footwear can lead to long-term savings through increased durability, potential tax incentives, and growing consumer demand for sustainable products.

Consumer Preferences: Green Sourcing Trends in Footwear

Consumer preferences in footwear increasingly favor eco-friendly sourcing due to rising environmental awareness and demand for sustainable products. Brands adopting green sourcing practices, such as using recycled materials and ethically sourced leather, report higher customer loyalty and market growth. Conventional sourcing faces challenges as transparency and sustainability become critical purchase drivers in the footwear industry.

Regulatory and Certification Standards

Eco-friendly sourcing in footwear adheres to stringent regulatory frameworks such as the Global Organic Textile Standard (GOTS) and the Forest Stewardship Council (FSC) certification to ensure sustainable material procurement and environmental impact reduction. Conventional sourcing often relies on less rigorous standards, with fewer mandates on chemical usage and waste management, leading to greater ecological footprints. Compliance with certifications like OEKO-TEX and Bluesign enhances transparency and accountability in eco-friendly supply chains, meeting increasing regulatory pressures worldwide.

Challenges and Barriers in Sustainable Sourcing

Eco-friendly sourcing in footwear faces significant challenges, including higher raw material costs and limited availability of sustainable fibers like organic cotton and recycled polyester. Conventional sourcing benefits from established supply chains and economies of scale, making sustainable alternatives harder to integrate without disrupting production timelines. Certification complexities and lack of transparency in supply networks further hinder the adoption of green materials across global footwear manufacturing.

Future Outlook: The Shift Toward Eco-Friendly Footwear

The future of footwear sourcing is rapidly shifting towards eco-friendly materials such as recycled plastics, organic cotton, and natural rubber, reducing environmental impact significantly. Brands adopting sustainable sourcing practices are responding to increasing consumer demand for transparency and ethical production, contributing to lower carbon footprints and waste reduction. Innovations in biodegradable materials and circular economy models are expected to dominate conventional sourcing, positioning eco-friendly footwear as the industry standard by 2030.

Eco-friendly Sourcing vs Conventional Sourcing Infographic

productdif.com

productdif.com