Limited batch production in food manufacturing ensures higher product quality and customization by producing small, controlled quantities ideal for specialty items and seasonal offerings. Continuous production maximizes efficiency and consistency by operating large-scale, nonstop processes best suited for staple food products and high-demand items. Both methods impact supply chain dynamics, cost management, and freshness standards depending on product type and market needs.

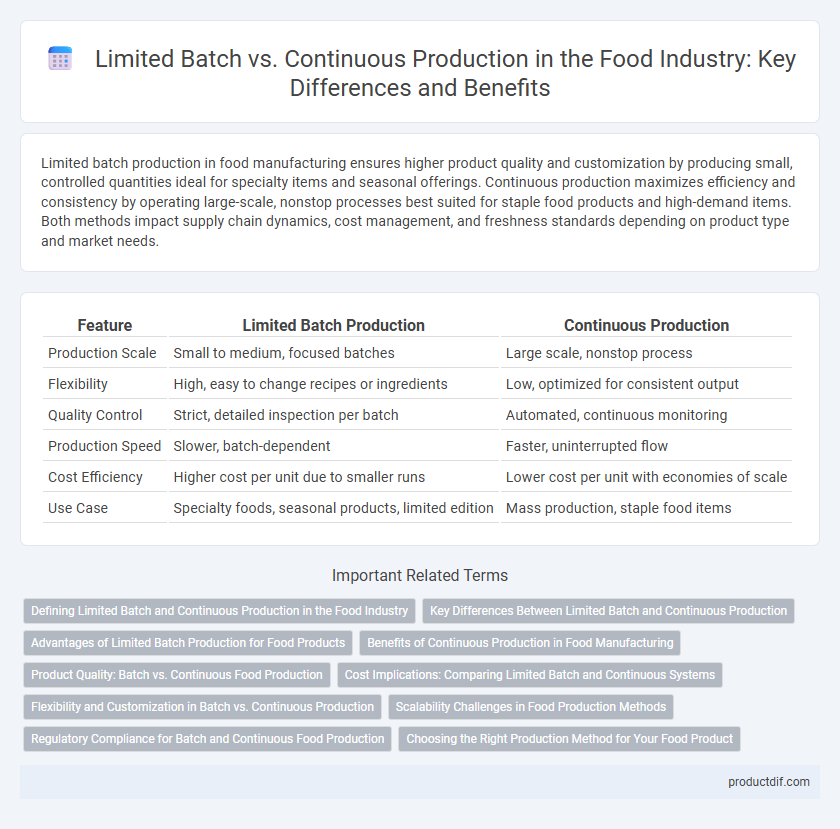

Table of Comparison

| Feature | Limited Batch Production | Continuous Production |

|---|---|---|

| Production Scale | Small to medium, focused batches | Large scale, nonstop process |

| Flexibility | High, easy to change recipes or ingredients | Low, optimized for consistent output |

| Quality Control | Strict, detailed inspection per batch | Automated, continuous monitoring |

| Production Speed | Slower, batch-dependent | Faster, uninterrupted flow |

| Cost Efficiency | Higher cost per unit due to smaller runs | Lower cost per unit with economies of scale |

| Use Case | Specialty foods, seasonal products, limited edition | Mass production, staple food items |

Defining Limited Batch and Continuous Production in the Food Industry

Limited batch production in the food industry involves creating specific quantities of products in defined runs, enhancing quality control and allowing for product variation or seasonal items. Continuous production operates on an ongoing basis, maximizing efficiency by producing large volumes of standardized food products without interruption. These production methods determine scalability, cost management, and flexibility in food manufacturing processes.

Key Differences Between Limited Batch and Continuous Production

Limited batch production involves manufacturing products in specific, finite quantities, allowing for flexibility and customization in food production. Continuous production operates on an ongoing basis, maximizing efficiency and consistency by producing large volumes without interruption. Key differences include scalability, product variety, and operational complexity, with batch production suited for specialty foods and continuous production ideal for high-demand staples.

Advantages of Limited Batch Production for Food Products

Limited batch production in the food industry allows for greater control over quality and freshness, ensuring each batch meets strict safety and taste standards. It supports product innovation by enabling the testing of new recipes and ingredients without large-scale risk. This approach also reduces waste and inventory costs, as production quantities closely match actual demand.

Benefits of Continuous Production in Food Manufacturing

Continuous production in food manufacturing enhances efficiency by enabling constant, uninterrupted operation that reduces downtime and increases output volume. This method improves product consistency and quality control through automated processes, ensuring uniformity across large batches. High scalability and reduced labor costs make continuous production ideal for meeting large market demands and optimizing resource utilization.

Product Quality: Batch vs. Continuous Food Production

Limited batch production often results in higher product quality due to greater control over ingredient selection, process parameters, and quality checks, enabling customization and consistency tailored to specific product goals. Continuous production, while more efficient for large-scale output, may compromise some aspects of quality control because of its focus on uniformity and speed, potentially leading to less flexibility in adjusting formulations or processes mid-run. Food manufacturers prioritize batch production for gourmet or specialty products where unique texture, flavor, and freshness are critical, whereas continuous production suits staple goods requiring consistent quality at high volumes.

Cost Implications: Comparing Limited Batch and Continuous Systems

Limited batch production often incurs higher per-unit costs due to frequent changeovers, equipment cleaning, and downtime, impacting labor and utility expenses. Continuous production systems benefit from economies of scale, lowering variable costs by maintaining steady operations and optimizing resource utilization. However, the initial capital investment for continuous systems can be significantly higher, influencing long-term cost efficiency and requiring careful financial planning.

Flexibility and Customization in Batch vs. Continuous Production

Limited batch production offers enhanced flexibility and customization by allowing manufacturers to tailor recipes and adjust ingredient quantities for small, distinct product runs. This method supports rapid product innovation and adaptation to seasonal or niche market demands without extensive retooling. Continuous production prioritizes efficiency and volume, making customization more challenging due to its standardized, high-speed processes that favor uniformity over variation.

Scalability Challenges in Food Production Methods

Limited batch production faces scalability challenges due to its reliance on manual labor and small-scale equipment, leading to inconsistent output and higher per-unit costs. Continuous production offers greater scalability by automating processes and enabling constant output, but it demands significant upfront investment and complex quality control to maintain food safety standards. Balancing flexibility in product variety with efficient large-scale operations remains a critical concern in scaling food production methods.

Regulatory Compliance for Batch and Continuous Food Production

Limited batch food production allows for easier traceability and quality control, facilitating compliance with regulatory standards such as FDA's Hazard Analysis Critical Control Points (HACCP) and the Food Safety Modernization Act (FSMA). Continuous production requires stringent monitoring systems and real-time data analytics to maintain consistent product safety and meet regulatory mandates, including Good Manufacturing Practices (GMP) and sanitation requirements. Both methods must ensure accurate record-keeping and allergen control to satisfy global food safety regulations and reduce the risk of recalls.

Choosing the Right Production Method for Your Food Product

Limited batch production suits artisanal and specialty food products requiring high-quality control and customization, ensuring unique flavors and small-scale exclusivity. Continuous production is ideal for mass-market items demanding consistent output, cost-efficiency, and uniform quality across large quantities. Evaluating product type, target market size, and quality standards guides the selection of the optimal manufacturing process.

Limited Batch vs Continuous Production Infographic

productdif.com

productdif.com