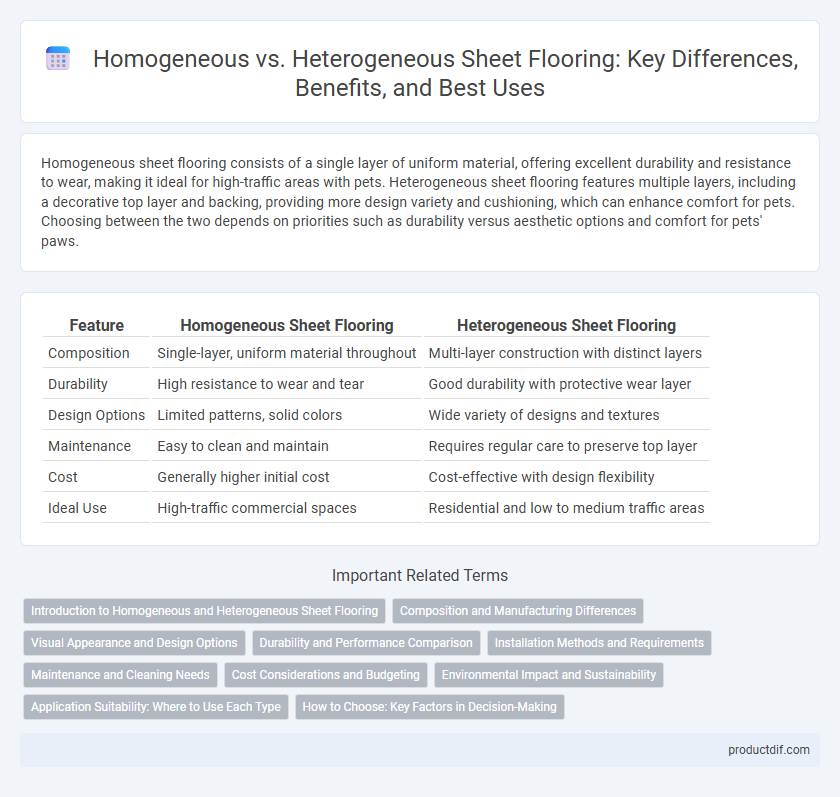

Homogeneous sheet flooring consists of a single layer of uniform material, offering excellent durability and resistance to wear, making it ideal for high-traffic areas with pets. Heterogeneous sheet flooring features multiple layers, including a decorative top layer and backing, providing more design variety and cushioning, which can enhance comfort for pets. Choosing between the two depends on priorities such as durability versus aesthetic options and comfort for pets' paws.

Table of Comparison

| Feature | Homogeneous Sheet Flooring | Heterogeneous Sheet Flooring |

|---|---|---|

| Composition | Single-layer, uniform material throughout | Multi-layer construction with distinct layers |

| Durability | High resistance to wear and tear | Good durability with protective wear layer |

| Design Options | Limited patterns, solid colors | Wide variety of designs and textures |

| Maintenance | Easy to clean and maintain | Requires regular care to preserve top layer |

| Cost | Generally higher initial cost | Cost-effective with design flexibility |

| Ideal Use | High-traffic commercial spaces | Residential and low to medium traffic areas |

Introduction to Homogeneous and Heterogeneous Sheet Flooring

Homogeneous sheet flooring consists of a single layer of vinyl material that provides uniformity in color and design throughout its thickness, ensuring durability and ease of maintenance. Heterogeneous sheet flooring features multiple layers, including a printed decorative layer and a wear layer that offers varied design options and enhanced protection against wear and tear. Both types are widely used in commercial and residential spaces, with selection often based on aesthetic preference and performance requirements.

Composition and Manufacturing Differences

Homogeneous sheets consist of a single material layer, typically vinyl, ensuring uniform composition and consistent wear resistance throughout, while heterogeneous sheets feature a multi-layer construction combining a PVC backing, design layer, and wear layer for enhanced aesthetic variety and durability. The manufacturing of homogeneous sheets involves continuous pressing and calendaring to create a dense, uniform sheet, whereas heterogeneous sheets are produced by assembling multiple layers through lamination and extrusion processes. These compositional and manufacturing differences impact performance, with homogeneous sheets often offering higher resilience and easier maintenance compared to the more design-flexible yet layered heterogeneous sheets.

Visual Appearance and Design Options

Homogeneous sheet flooring offers a consistent visual appearance with a uniform color and pattern throughout the material, providing a seamless and smooth finish ideal for high-traffic areas. Heterogeneous sheet flooring features multiple layers with a printed design layer, allowing for a wide variety of patterns, textures, and colors that mimic natural materials like wood or stone. The diverse design options of heterogeneous sheets enable more customization and aesthetic variety compared to the simpler, solid look of homogeneous sheets.

Durability and Performance Comparison

Homogeneous sheet flooring, made from a single layer of vinyl, offers superior durability and resistance to wear, making it ideal for high-traffic commercial areas. Heterogeneous sheet flooring consists of multiple layers, including a wear layer and printed design layer, providing enhanced aesthetic options but generally less abrasion resistance compared to homogeneous sheets. Performance-wise, homogeneous sheets excel in longevity and ease of maintenance, while heterogeneous sheets deliver better design versatility with moderate durability.

Installation Methods and Requirements

Homogeneous sheet flooring requires seamless welding of joints using heat or chemical welding methods to ensure water-tight integrity, suitable for high-traffic commercial environments. Heterogeneous sheet flooring installation involves heat welding, cold welding, or adhesive bonding, with an emphasis on precise subfloor preparation to accommodate multiple layers that enhance durability and design flexibility. Both types demand a smooth, clean, and level subfloor to prevent imperfections and ensure long-lasting adhesion.

Maintenance and Cleaning Needs

Homogeneous sheet flooring offers superior durability with a uniform composition that resists stains, making it easier to clean and maintain over time. Heterogeneous sheet flooring, composed of multiple layers, may require more careful maintenance to prevent damage to the printed design layer and often benefits from regular sealing. Both types perform well in commercial settings, but homogeneous sheets typically demand less intensive cleaning routines due to their seamless surface.

Cost Considerations and Budgeting

Homogeneous sheet flooring generally incurs higher initial costs due to its uniform composition and greater durability, which can lead to lower long-term maintenance expenses. Heterogeneous sheet flooring offers a more budget-friendly upfront investment with varied layers that may require more frequent replacement or repairs, impacting overall lifecycle costs. Careful budgeting must account for both the purchase price and potential maintenance or replacement frequency to ensure cost-effectiveness in flooring projects.

Environmental Impact and Sustainability

Homogeneous sheet flooring typically consists of a single layer of material, making it easier to recycle and contributing to lower environmental impact compared to heterogeneous sheets, which contain multiple layers that complicate recycling processes. The production of homogeneous sheets often uses fewer raw materials and results in less waste, enhancing sustainability efforts. Heterogeneous sheets may offer more design flexibility but generally pose greater challenges in disposal and resource recovery, affecting their overall environmental footprint.

Application Suitability: Where to Use Each Type

Homogeneous sheet flooring, characterized by a uniform composition throughout its thickness, suits high-traffic commercial spaces and healthcare facilities where durability and ease of maintenance are critical. Heterogeneous sheet flooring, composed of multiple layers including a print film layer, offers diverse design options and better comfort, making it ideal for residential areas, offices, and retail environments. The choice depends on balancing performance requirements with aesthetic preferences and budget constraints.

How to Choose: Key Factors in Decision-Making

Choosing between homogeneous and heterogeneous sheet flooring depends on factors such as durability requirements, budget constraints, and installation environment. Homogeneous sheets offer uniform composition ideal for high-traffic commercial areas, while heterogeneous sheets provide design versatility through layered construction suitable for diverse aesthetic preferences. Assessing factors like wear resistance, maintenance needs, and cost-effectiveness ensures an informed flooring material decision.

Homogeneous Sheet vs Heterogeneous Sheet Infographic

productdif.com

productdif.com