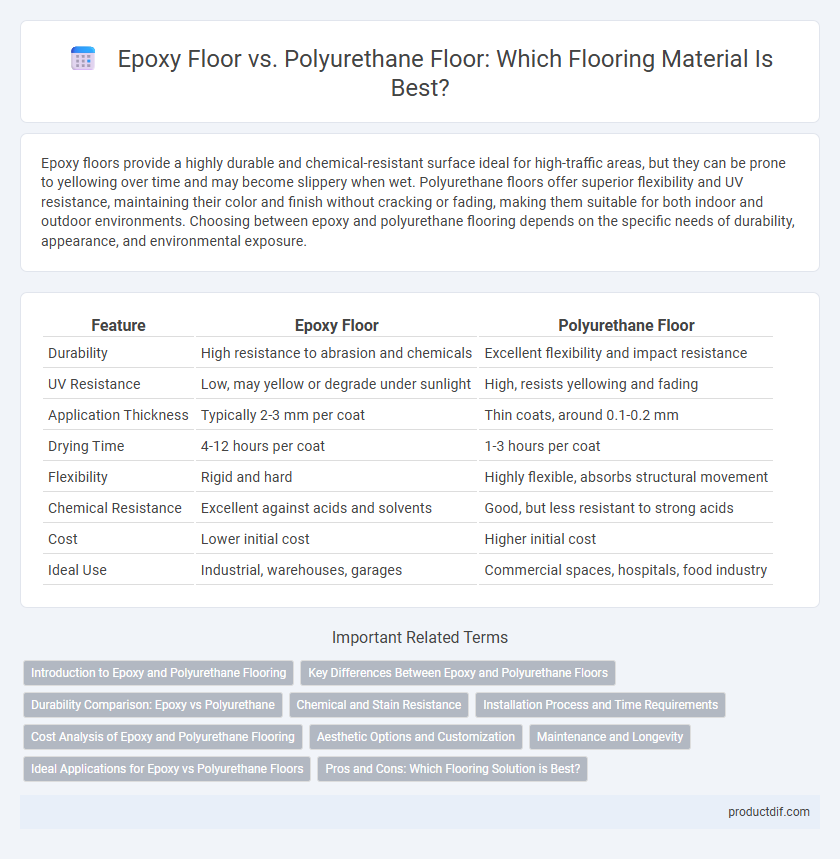

Epoxy floors provide a highly durable and chemical-resistant surface ideal for high-traffic areas, but they can be prone to yellowing over time and may become slippery when wet. Polyurethane floors offer superior flexibility and UV resistance, maintaining their color and finish without cracking or fading, making them suitable for both indoor and outdoor environments. Choosing between epoxy and polyurethane flooring depends on the specific needs of durability, appearance, and environmental exposure.

Table of Comparison

| Feature | Epoxy Floor | Polyurethane Floor |

|---|---|---|

| Durability | High resistance to abrasion and chemicals | Excellent flexibility and impact resistance |

| UV Resistance | Low, may yellow or degrade under sunlight | High, resists yellowing and fading |

| Application Thickness | Typically 2-3 mm per coat | Thin coats, around 0.1-0.2 mm |

| Drying Time | 4-12 hours per coat | 1-3 hours per coat |

| Flexibility | Rigid and hard | Highly flexible, absorbs structural movement |

| Chemical Resistance | Excellent against acids and solvents | Good, but less resistant to strong acids |

| Cost | Lower initial cost | Higher initial cost |

| Ideal Use | Industrial, warehouses, garages | Commercial spaces, hospitals, food industry |

Introduction to Epoxy and Polyurethane Flooring

Epoxy flooring is a durable resin-based material known for its high resistance to chemicals, abrasion, and heavy traffic, making it ideal for industrial and commercial applications. Polyurethane flooring, composed of elastomeric polymers, offers superior flexibility, UV resistance, and a smooth finish suitable for areas requiring impact absorption and outdoor exposure. Both materials provide strong adhesion to concrete substrates and long-lasting performance but are selected based on specific environmental and functional demands.

Key Differences Between Epoxy and Polyurethane Floors

Epoxy floors offer superior chemical resistance and durability, making them ideal for industrial and commercial environments, while polyurethane floors excel in flexibility and UV resistance, suited for outdoor and high-traffic areas. Epoxy coatings typically have a harder finish but can become brittle over time, whereas polyurethane provides better impact resistance and retains color stability under prolonged sunlight exposure. Installation time also differs, with epoxy curing faster but polyurethane allowing for easier maintenance and repair.

Durability Comparison: Epoxy vs Polyurethane

Epoxy floors offer exceptional hardness and resistance to wear, making them ideal for heavy traffic and industrial environments. Polyurethane floors provide superior flexibility and UV resistance, preventing cracking and yellowing over time, especially in areas exposed to sunlight. Both materials boast high durability, but epoxy excels in impact resistance while polyurethane outperforms in elasticity and longevity under varying temperatures.

Chemical and Stain Resistance

Epoxy floors offer superior chemical resistance, making them ideal for industrial environments where exposure to harsh chemicals is frequent, while polyurethane floors provide excellent stain resistance and UV stability, reducing discoloration over time. Epoxy coatings create a hard, durable surface impervious to oils, acids, and solvents, whereas polyurethane floors are more flexible and resistant to abrasion and yellowing. Choosing between epoxy and polyurethane depends on the specific needs for chemical exposure and aesthetic maintenance in commercial or residential settings.

Installation Process and Time Requirements

Epoxy floors require a detailed surface preparation including cleaning, etching, and priming, with curing times ranging from 24 to 72 hours depending on thickness and environmental conditions. Polyurethane floors benefit from faster curing rates, often becoming walkable within 6 to 12 hours, and demand fewer steps in surface treatment, typically just thorough cleaning and primer application. The quicker installation and reduced downtime make polyurethane a preferred choice for projects with tight schedules or continuous industrial activity.

Cost Analysis of Epoxy and Polyurethane Flooring

Epoxy flooring typically costs between $3 to $12 per square foot, offering a durable and chemical-resistant surface ideal for industrial settings, while polyurethane flooring ranges from $4 to $7 per square foot, prized for its flexibility and UV resistance. Installation expenses for epoxy tend to be lower due to faster curing times, whereas polyurethane requires more labor and time, increasing labor costs. Long-term maintenance expenses favor polyurethane floors, which resist cracking and discoloration better, offsetting higher initial costs over time.

Aesthetic Options and Customization

Epoxy floors offer high-gloss finishes with vibrant color options and the ability to incorporate decorative elements like flakes, metallic pigments, and logos, providing extensive design versatility. Polyurethane floors provide a softer, matte to satin finish with enhanced UV resistance, making them ideal for areas requiring color stability and subtle aesthetics. Both materials allow custom textures and patterns, but epoxy typically supports more bold and eye-catching customization, while polyurethane favors a more refined, natural look.

Maintenance and Longevity

Epoxy floors require regular cleaning and occasional reapplication every 3-5 years to maintain their durability and gloss, making them ideal for high-traffic commercial areas. Polyurethane floors offer superior UV resistance and flexibility, resulting in less yellowing and cracking over time, which extends their lifespan up to 10-15 years with minimal maintenance. Both materials demand proper surface preparation, but polyurethane's enhanced abrasion resistance reduces long-term maintenance costs compared to epoxy.

Ideal Applications for Epoxy vs Polyurethane Floors

Epoxy floors are ideal for industrial and commercial settings requiring high durability, chemical resistance, and easy maintenance, such as warehouses, factories, and garages. Polyurethane floors excel in environments needing flexibility, UV resistance, and impact absorption, making them suitable for outdoor spaces, sports facilities, and residential areas with high foot traffic. Selecting between epoxy and polyurethane floors depends on specific use cases, where epoxy is preferred for heavy-duty applications and polyurethane for versatility and comfort.

Pros and Cons: Which Flooring Solution is Best?

Epoxy floors offer exceptional durability, chemical resistance, and a high-gloss finish ideal for industrial and commercial settings, but they can be prone to yellowing and may become brittle over time. Polyurethane floors provide superior UV resistance, flexibility, and abrasion resistance, making them suitable for areas with heavy foot traffic and outdoor applications, although they tend to be less hard than epoxy and require a longer curing time. Choosing the best flooring solution depends on the specific environmental conditions and maintenance priorities, with epoxy favored for chemical-heavy environments and polyurethane preferred for UV exposure and impact resistance.

Epoxy Floor vs Polyurethane Floor Infographic

productdif.com

productdif.com