Concrete staining enhances flooring by penetrating the surface to add vibrant color and unique patterns, creating a decorative finish that highlights the natural texture of concrete. Concrete polishing, on the other hand, involves grinding the concrete surface to a smooth, glossy finish that increases durability, reduces maintenance, and reflects light for a brighter space. Choosing between staining and polishing depends on whether the priority is aesthetic customization or a sleek, resilient surface ideal for high-traffic areas.

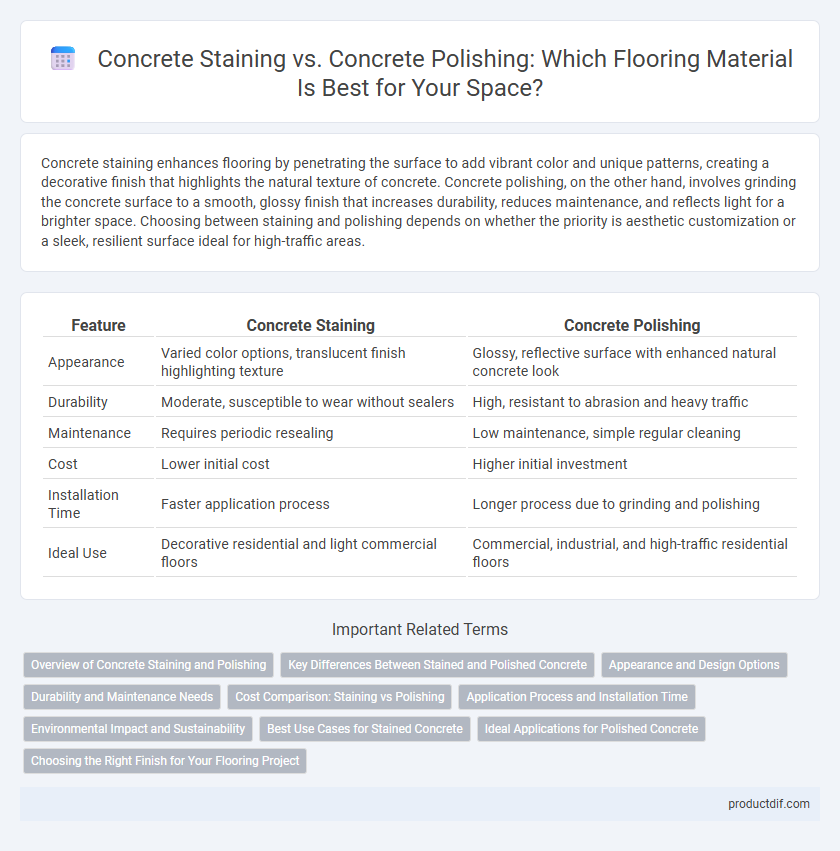

Table of Comparison

| Feature | Concrete Staining | Concrete Polishing |

|---|---|---|

| Appearance | Varied color options, translucent finish highlighting texture | Glossy, reflective surface with enhanced natural concrete look |

| Durability | Moderate, susceptible to wear without sealers | High, resistant to abrasion and heavy traffic |

| Maintenance | Requires periodic resealing | Low maintenance, simple regular cleaning |

| Cost | Lower initial cost | Higher initial investment |

| Installation Time | Faster application process | Longer process due to grinding and polishing |

| Ideal Use | Decorative residential and light commercial floors | Commercial, industrial, and high-traffic residential floors |

Overview of Concrete Staining and Polishing

Concrete staining enhances surfaces through chemical reactions that infuse translucent color into the concrete, creating rich, variegated patterns ideal for decorative flooring. Concrete polishing involves mechanically grinding and buffing the surface to achieve a smooth, reflective finish, improving durability and ease of maintenance. Both methods optimize concrete aesthetics, with staining focusing on color customization and polishing emphasizing surface smoothness and shine.

Key Differences Between Stained and Polished Concrete

Concrete staining penetrates the surface to create rich, translucent color variations enhancing texture, while concrete polishing mechanically grinds the surface to achieve a smooth, reflective finish. Stained concrete offers greater color customization through acid or water-based stains, whereas polished concrete emphasizes durability and low maintenance with its sealed, glossy appearance. The choice depends on design preferences, with staining suited for artistic effects and polishing favored for high-traffic, modern industrial spaces.

Appearance and Design Options

Concrete staining offers a rich variety of translucent color tones that enhance the natural texture and grain of the concrete, creating a warm, mottled appearance ideal for decorative floors. Concrete polishing delivers a sleek, high-gloss finish with a mirror-like surface that highlights the aggregate and provides a modern, reflective aesthetic. While staining allows for customizable patterns and color layering, polishing emphasizes texture contrast and surface smoothness, offering distinct design possibilities for both industrial and residential spaces.

Durability and Maintenance Needs

Concrete staining creates a durable surface with a penetrating color finish that resists fading and requires minimal maintenance, often only needing occasional resealing to preserve its appearance. Concrete polishing transforms the surface into a smooth, glossy finish that enhances durability by increasing resistance to abrasion but demands regular cleaning and periodic re-polishing to maintain its shine. Both methods offer long-lasting solutions, but concrete polishing typically requires more consistent upkeep to sustain its aesthetic appeal over time.

Cost Comparison: Staining vs Polishing

Concrete staining generally costs between $2 to $6 per square foot, making it a more budget-friendly option compared to concrete polishing, which ranges from $3 to $12 per square foot depending on the level of finish and equipment used. Staining involves applying chemical dyes to enhance color and texture, resulting in lower labor and material costs, while polishing requires extensive grinding, honing, and sealing, increasing the project's overall price. Choosing between staining and polishing depends on budget constraints and desired aesthetics, with staining offering affordable customization and polishing providing a durable, high-gloss finish.

Application Process and Installation Time

Concrete staining involves applying acid-based or water-based stains that penetrate the surface, requiring several hours to dry and cure, typically taking one to two days for completion depending on the project size. Concrete polishing is a mechanical process using progressively finer diamond abrasives to grind and polish the surface, often completed in one day for residential floors but may extend to multiple days in commercial settings. Staining allows for color customization and retains the concrete's texture, while polishing enhances durability and produces a glossy, reflective finish with minimal downtime.

Environmental Impact and Sustainability

Concrete staining uses water-based or acid-based dyes that may contain chemicals impacting indoor air quality, whereas concrete polishing involves mechanically grinding the surface to enhance durability without introducing harmful substances. Polished concrete is highly sustainable due to its longevity and reduced need for coatings or sealants, thereby minimizing waste and chemical use over time. Stained concrete often requires periodic reapplication, increasing resource consumption compared to the long-lasting and low-maintenance polished alternative.

Best Use Cases for Stained Concrete

Stained concrete is ideal for decorative applications where color customization and aesthetic appeal are priorities, such as residential interiors, commercial lobbies, and retail spaces. Its ability to penetrate and react chemically with the concrete surface makes it perfect for enhancing existing concrete with vibrant, lasting hues and natural variations. Stained concrete works best in areas with moderate foot traffic where decorative finishes are preferred over the high-gloss, low-maintenance qualities of polished concrete.

Ideal Applications for Polished Concrete

Polished concrete is ideal for high-traffic commercial spaces, warehouses, and modern residential interiors where durability and low maintenance are priorities. Its reflective surface enhances natural light, making it suitable for retail stores, showrooms, and office environments seeking a sleek, professional aesthetic. Unlike concrete staining, polished concrete provides a smooth, resilient finish resistant to abrasion and stains, perfect for areas demanding long-lasting performance.

Choosing the Right Finish for Your Flooring Project

Concrete staining infuses color into the surface, offering a vibrant, customizable look ideal for decorative flooring projects. Concrete polishing creates a glossy, durable finish by grinding and buffing the surface, enhancing both aesthetics and longevity in high-traffic areas. Selecting the right finish depends on desired appearance, maintenance preferences, and the specific use of the flooring space.

Concrete Staining vs Concrete Polishing Infographic

productdif.com

productdif.com