Hard-anodized cookware offers superior durability and corrosion resistance, making it ideal for high-heat cooking and everyday use. Enameled cookware provides a non-reactive surface that prevents food from sticking and allows for easy cleaning, especially suited for delicate dishes. Choosing between the two depends on your cooking style and maintenance preferences, with hard-anodized excelling in toughness and enameled excelling in ease of use.

Table of Comparison

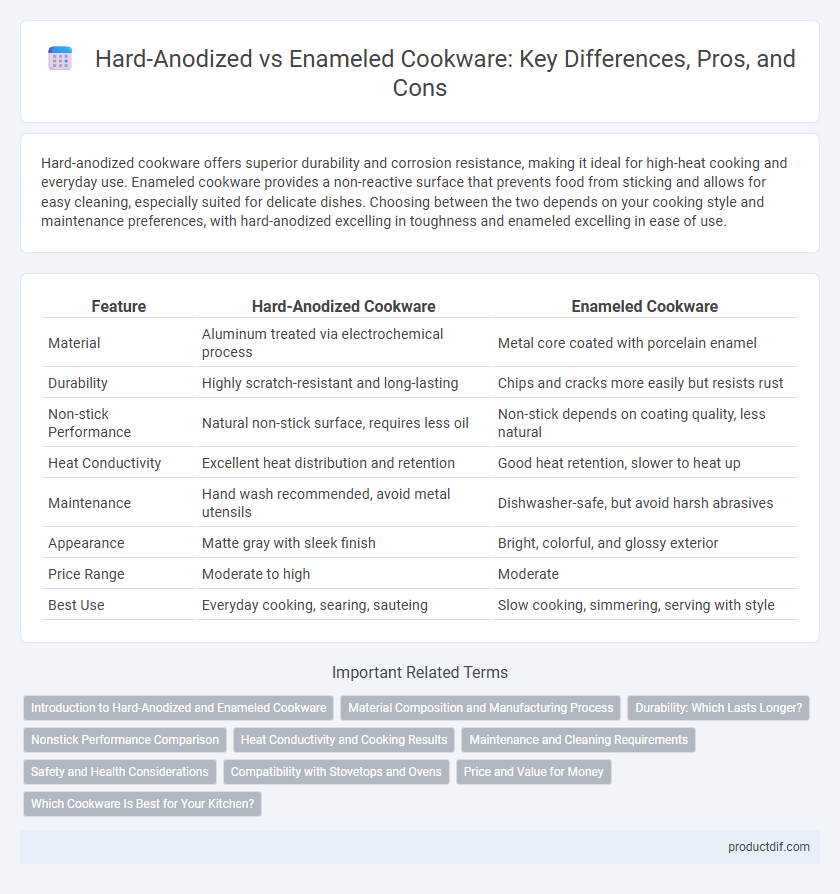

| Feature | Hard-Anodized Cookware | Enameled Cookware |

|---|---|---|

| Material | Aluminum treated via electrochemical process | Metal core coated with porcelain enamel |

| Durability | Highly scratch-resistant and long-lasting | Chips and cracks more easily but resists rust |

| Non-stick Performance | Natural non-stick surface, requires less oil | Non-stick depends on coating quality, less natural |

| Heat Conductivity | Excellent heat distribution and retention | Good heat retention, slower to heat up |

| Maintenance | Hand wash recommended, avoid metal utensils | Dishwasher-safe, but avoid harsh abrasives |

| Appearance | Matte gray with sleek finish | Bright, colorful, and glossy exterior |

| Price Range | Moderate to high | Moderate |

| Best Use | Everyday cooking, searing, sauteing | Slow cooking, simmering, serving with style |

Introduction to Hard-Anodized and Enameled Cookware

Hard-anodized cookware features aluminum treated through an electrochemical process, resulting in a durable, non-reactive surface resistant to scratches and corrosion. Enameled cookware consists of a metal core, often cast iron or steel, coated with a smooth, glass-like porcelain enamel that prevents rust and offers easy cleaning. Both types provide excellent heat retention and durability but differ significantly in maintenance and cooking performance.

Material Composition and Manufacturing Process

Hard-anodized cookware is made by electrochemically treating aluminum, creating a dense, non-reactive surface that enhances durability and heat conduction. Enameled cookware consists of cast iron or steel coated with a layer of vitreous enamel, formed by fusing powdered glass onto the metal at high temperatures, providing a non-porous and corrosion-resistant finish. The manufacturing process of hard-anodized involves anodizing for increased hardness, while enameled cookware relies on glass fusing techniques for its protective, colorful coating.

Durability: Which Lasts Longer?

Hard-anodized cookware features a dense, non-porous surface created through electrochemical treatment, providing exceptional scratch and corrosion resistance that significantly extends its lifespan. Enameled cookware, coated with a layer of vitreous enamel, offers excellent heat retention but is prone to chipping and cracking over time, which can compromise durability. Hard-anodized pans generally last longer due to their robust, metal-infused construction that withstands heavy daily use and abrasive cleaning methods better than enameled surfaces.

Nonstick Performance Comparison

Hard-anodized cookware features a dense, non-reactive surface that offers superior durability and natural nonstick properties, allowing for easy food release and minimal oil usage. Enameled cookware, coated with a glass-like layer, provides a smooth nonstick surface but can be prone to chipping and requires more careful handling to maintain performance. In terms of nonstick efficiency, hard-anodized pans generally outperform enameled ones due to their robust construction and enhanced resistance to scratching and wear.

Heat Conductivity and Cooking Results

Hard-anodized cookware offers superior heat conductivity due to its dense aluminum core, ensuring even heat distribution and reducing hot spots for consistent cooking results. Enameled cookware, often made with cast iron or steel, retains heat effectively but warms up more slowly and provides excellent heat retention for simmering and slow-cooking dishes. Choosing between the two depends on whether quick, uniform heating or prolonged, steady heat retention is desired for specific cooking techniques.

Maintenance and Cleaning Requirements

Hard-anodized cookware features a durable, non-porous surface resistant to scratches and corrosion, requiring gentle hand washing to maintain its protective layer and avoid abrasive cleaners. Enameled cookware, coated with a vitreous enamel layer over metal, resists staining and can often be cleaned with mild detergents and warm water, though avoiding metal utensils is crucial to prevent chipping. Both materials demand specific maintenance: hard-anodized pans should not be soaked for long periods, while enameled cookware benefits from drying thoroughly to avoid rust on exposed metal edges.

Safety and Health Considerations

Hard-anodized cookware features a non-porous, durable surface that resists scratching and prevents aluminum leaching, ensuring safer cooking without harmful chemicals. Enameled cookware offers a glass coating over metal, eliminating direct metal contact and reducing risks of reactive chemical exposure, making it ideal for acidic foods. Both types provide health-conscious options, but enameled cookware's inert surface poses fewer concerns regarding metal reactivity or coating wear over time.

Compatibility with Stovetops and Ovens

Hard-anodized cookware offers superior compatibility with induction and electric stovetops due to its conductive aluminum core, while enameled cookware works well on gas, electric, and ceramic stovetops but may struggle with induction unless it has a magnetic base. Both types are oven-safe, yet hard-anodized pans typically withstand higher oven temperatures up to 500degF, whereas enameled cookware usually tolerates temperatures up to 350degF to 450degF depending on the manufacturer's specifications. Choosing between them depends on your stovetop type and preferred cooking temperature range for optimal performance and durability.

Price and Value for Money

Hard-anodized cookware typically costs more upfront but offers superior durability and non-stick performance, making it a cost-effective investment for frequent cooking. Enameled cookware is often priced lower and provides excellent heat retention and aesthetic appeal, yet it may chip or crack over time, potentially reducing its long-term value. Evaluating the balance between initial price and lifespan helps determine which option delivers better value for money based on cooking habits and care preferences.

Which Cookware Is Best for Your Kitchen?

Hard-anodized cookware offers superior durability, scratch resistance, and even heat distribution, making it ideal for heavy-duty cooking and daily use. Enameled cookware provides a non-reactive, easy-to-clean surface suitable for acidic dishes and slow-cooking methods, preserving flavor without metallic taste. Choosing between hard-anodized and enameled cookware depends on your cooking style, with hard-anodized excelling in high-heat searing and enameled perfect for simmering and oven use.

Hard-Anodized vs Enameled Infographic

productdif.com

productdif.com