Hard-anodized cookware offers superior durability and scratch resistance compared to aluminum cookware, which is softer and prone to dents. The non-reactive surface of hard-anodized pots and pans prevents food from absorbing metallic tastes, unlike untreated aluminum that can react with acidic ingredients. Consumers valuing longevity and non-stick performance often prefer hard-anodized cookware, while aluminum remains popular for its lightweight and budget-friendly qualities.

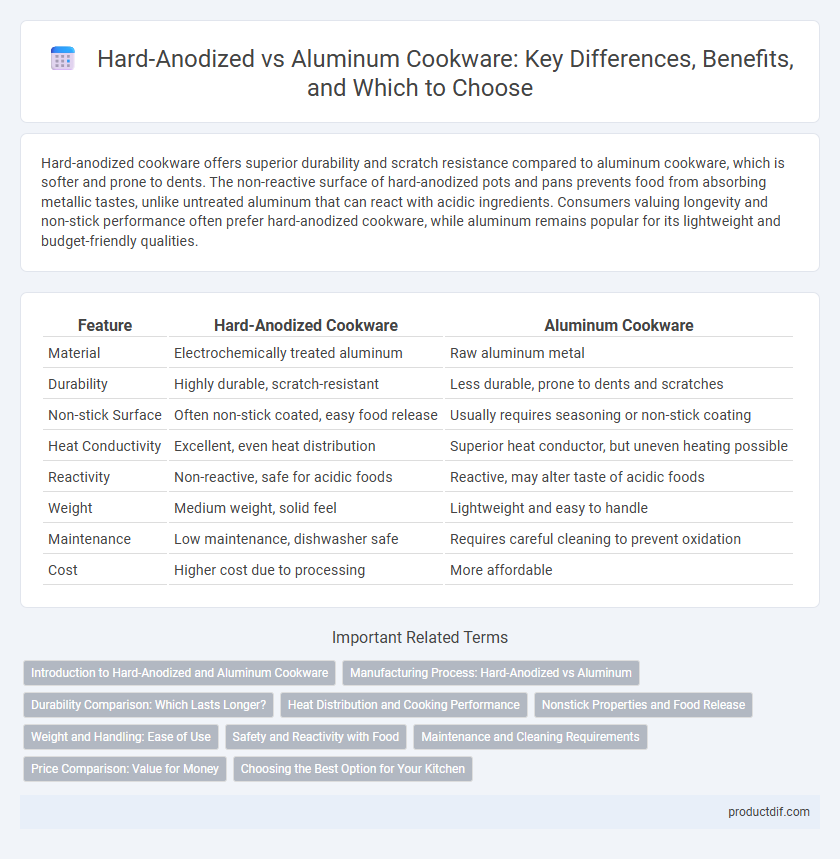

Table of Comparison

| Feature | Hard-Anodized Cookware | Aluminum Cookware |

|---|---|---|

| Material | Electrochemically treated aluminum | Raw aluminum metal |

| Durability | Highly durable, scratch-resistant | Less durable, prone to dents and scratches |

| Non-stick Surface | Often non-stick coated, easy food release | Usually requires seasoning or non-stick coating |

| Heat Conductivity | Excellent, even heat distribution | Superior heat conductor, but uneven heating possible |

| Reactivity | Non-reactive, safe for acidic foods | Reactive, may alter taste of acidic foods |

| Weight | Medium weight, solid feel | Lightweight and easy to handle |

| Maintenance | Low maintenance, dishwasher safe | Requires careful cleaning to prevent oxidation |

| Cost | Higher cost due to processing | More affordable |

Introduction to Hard-Anodized and Aluminum Cookware

Hard-anodized cookware features aluminum that has undergone an electrochemical process to create a durable, non-reactive surface resistant to scratches and corrosion. Aluminum cookware is prized for its excellent heat conductivity and lightweight properties but often requires a non-stick coating or anodization to prevent reactions with acidic foods. Both types offer unique advantages, with hard-anodized cookware providing enhanced durability and aluminum cookware excelling in rapid, even heat distribution.

Manufacturing Process: Hard-Anodized vs Aluminum

Hard-anodized cookware undergoes an electrochemical treatment that thickens and hardens the aluminum surface, creating a durable, non-porous oxide layer resistant to corrosion and scratching. In contrast, standard aluminum cookware is typically made by casting or rolling pure aluminum without additional surface treatment, resulting in a softer, more reactive material prone to wear. The hard-anodizing process significantly enhances the strength, heat conduction, and longevity of aluminum cookware compared to untreated aluminum.

Durability Comparison: Which Lasts Longer?

Hard-anodized cookware offers superior durability compared to standard aluminum due to its dense, non-porous surface that resists scratches, corrosion, and warping. Aluminum pans, while lightweight and heat-conductive, are prone to denting and surface degradation over time, especially without protective coatings. The prolonged lifespan of hard-anodized cookware makes it a preferred choice for long-term kitchen use.

Heat Distribution and Cooking Performance

Hard-anodized cookware features a dense, non-porous surface that ensures even heat distribution and enhanced durability compared to standard aluminum. Aluminum conducts heat quickly but can develop hot spots, potentially causing uneven cooking and requiring lower temperatures to prevent warping. The hard-anodized process improves aluminum's heat retention and resistance to corrosion, resulting in superior cooking performance and consistent results.

Nonstick Properties and Food Release

Hard-anodized cookware features a dense, non-porous surface that enhances nonstick properties and promotes effortless food release, reducing the need for excessive oils or fats. Aluminum cookware, while lightweight and fast-heating, often requires a nonstick coating to prevent food from sticking, which may degrade over time. The durability of the hard-anodized surface ensures long-lasting performance and consistent nonstick behavior compared to coated aluminum pans.

Weight and Handling: Ease of Use

Hard-anodized cookware is generally heavier than aluminum but offers enhanced durability and a solid, stable feel during cooking. Aluminum cookware's lightweight construction makes it easier to handle and maneuver, ideal for quick stovetop movements and frequent lifting. Both materials provide excellent heat conduction; however, aluminum excels in ease of use due to its lighter weight.

Safety and Reactivity with Food

Hard-anodized cookware offers superior safety and reduced reactivity compared to traditional aluminum due to its non-porous, durable surface that prevents aluminum leaching into food. Aluminum pans can react with acidic or alkaline ingredients, causing metallic taste and potential health concerns. Choosing hard-anodized cookware minimizes chemical interactions, ensuring food safety and preserving flavor integrity during cooking.

Maintenance and Cleaning Requirements

Hard-anodized cookware features a durable, non-porous surface that resists scratching and corrosion, requiring gentle cleaning with non-abrasive sponges and mild detergents to maintain its finish. Aluminum cookware, while lightweight and excellent for heat conduction, tends to react with acidic foods and can discolor or warp over time, necessitating hand washing and avoidance of harsh scrubbing or metal utensils. Proper maintenance of hard-anodized pots extends their lifespan, while aluminum pans need more careful handling to prevent surface damage and maintain cooking performance.

Price Comparison: Value for Money

Hard-anodized cookware typically costs more than aluminum due to its enhanced durability and non-reactive surface. Aluminum pans offer an affordable option but may sacrifice longevity and performance under high heat. Investing in hard-anodized cookware provides better value for money with its resistance to scratches, corrosion, and even heat distribution, justifying the higher initial price.

Choosing the Best Option for Your Kitchen

Hard-anodized cookware offers superior durability, non-reactive surfaces, and excellent heat distribution, making it ideal for long-term kitchen use. Aluminum cookware is lightweight and affordable but tends to be less resistant to scratches and warping, which may affect performance over time. Choosing between hard-anodized and aluminum depends on balancing budget, cooking habits, and the desired longevity of the cookware set.

Hard-Anodized vs Aluminum Infographic

productdif.com

productdif.com