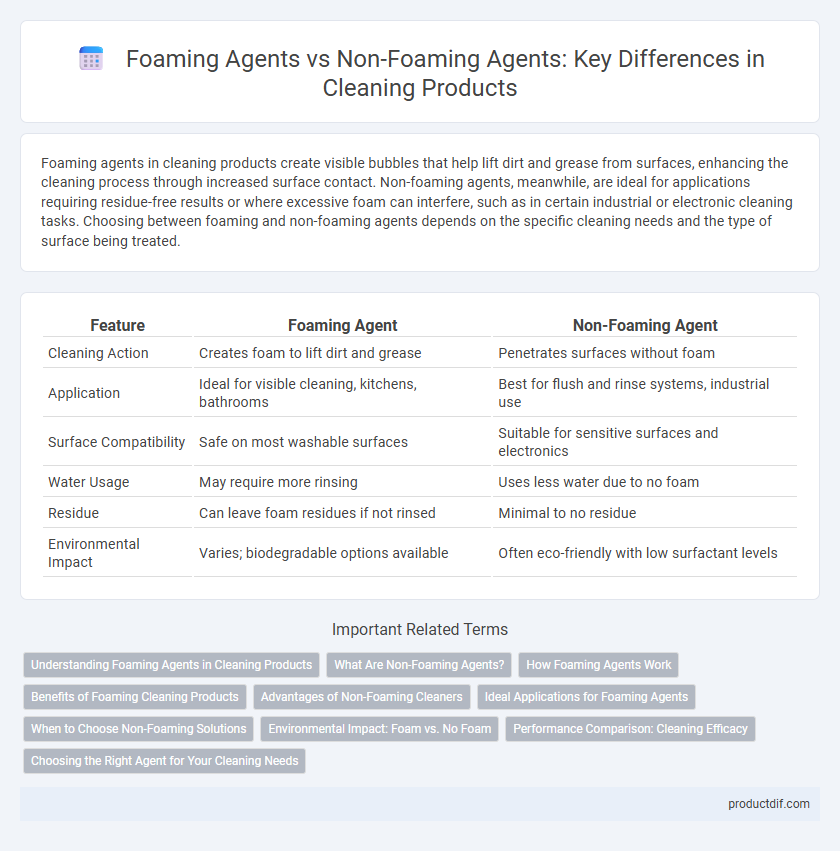

Foaming agents in cleaning products create visible bubbles that help lift dirt and grease from surfaces, enhancing the cleaning process through increased surface contact. Non-foaming agents, meanwhile, are ideal for applications requiring residue-free results or where excessive foam can interfere, such as in certain industrial or electronic cleaning tasks. Choosing between foaming and non-foaming agents depends on the specific cleaning needs and the type of surface being treated.

Table of Comparison

| Feature | Foaming Agent | Non-Foaming Agent |

|---|---|---|

| Cleaning Action | Creates foam to lift dirt and grease | Penetrates surfaces without foam |

| Application | Ideal for visible cleaning, kitchens, bathrooms | Best for flush and rinse systems, industrial use |

| Surface Compatibility | Safe on most washable surfaces | Suitable for sensitive surfaces and electronics |

| Water Usage | May require more rinsing | Uses less water due to no foam |

| Residue | Can leave foam residues if not rinsed | Minimal to no residue |

| Environmental Impact | Varies; biodegradable options available | Often eco-friendly with low surfactant levels |

Understanding Foaming Agents in Cleaning Products

Foaming agents in cleaning products create bubbles that help lift dirt and grease by trapping and suspending particles, enhancing the overall cleaning efficiency. Non-foaming agents rely on surfactants and solvents without producing foam, making them ideal for applications requiring minimal residue or quick rinse-off. Understanding the role of foaming agents aids in selecting the right cleaning solution for specific tasks, balancing effectiveness and ease of use.

What Are Non-Foaming Agents?

Non-foaming agents are cleaning ingredients designed to minimize or eliminate foam formation during use, making them ideal for applications where residue or excess bubbles can interfere with cleaning effectiveness. These agents improve cleaning efficiency in industrial and commercial settings by promoting faster rinsing and reducing water consumption. Unlike foaming agents, non-foaming agents maintain product performance without compromising clarity or surface contact.

How Foaming Agents Work

Foaming agents in cleaning products work by reducing surface tension between liquids and solids, allowing the solution to spread more easily and trap dirt and grease within bubbles. These agents create stable foam by incorporating air into the liquid, which enhances the mechanical action during scrubbing and improves the removal of contaminants. In contrast, non-foaming agents prioritize surface penetration and emulsification without producing bubbles, making them ideal for tasks requiring less residue and quick rinsing.

Benefits of Foaming Cleaning Products

Foaming cleaning products enhance soil suspension and removal by generating bubbles that increase surface contact and agitation, improving overall cleaning efficiency. The foam visually indicates coverage, ensuring users apply the product evenly and minimizing waste. These products often require less water and rinse time, making them environmentally friendly and cost-effective for both household and industrial cleaning applications.

Advantages of Non-Foaming Cleaners

Non-foaming cleaners offer superior rinsing efficiency, reducing residue buildup on surfaces and minimizing water usage during cleaning. These agents excel in environments requiring clear visibility or delicate surfaces, such as glass or electronic equipment, where foam could obstruct cleaning or cause damage. Their low-foam formulation ensures faster application and drying times, enhancing overall cleaning productivity and user convenience.

Ideal Applications for Foaming Agents

Foaming agents are ideal for cleaning applications requiring enhanced soil suspension and surface contact, such as carpets, upholstery, and hard-to-reach crevices. Their ability to create stable foam helps lift and encapsulate dirt, making them effective in both industrial and household cleaning tasks where visible foam improves user confidence. These agents excel in use cases involving vertical surfaces or porous materials, where foam retention prolongs cleaning action and reduces runoff.

When to Choose Non-Foaming Solutions

Non-foaming cleaning agents are ideal for situations where residue buildup or rinsing difficulty must be minimized, such as in industrial machinery or electronic components. These solutions provide effective dirt and grease removal while preventing foam-related blockages or damage to sensitive surfaces. Choosing non-foaming products ensures efficient cleaning in environments requiring low suds for optimal performance and safety.

Environmental Impact: Foam vs. No Foam

Foaming agents in cleaning products often contain surfactants that can contribute to water pollution and harm aquatic ecosystems due to persistent chemical residues. Non-foaming agents typically use biodegradable ingredients that minimize environmental impact by breaking down more easily and reducing toxicity. Choosing non-foaming formulas helps lower the ecological footprint by preventing foam accumulation and promoting safer wastewater discharge.

Performance Comparison: Cleaning Efficacy

Foaming agents enhance cleaning efficacy by trapping and lifting dirt particles more effectively, creating a rich lather that penetrates surfaces for deeper soil removal. Non-foaming agents often rely on chemical surfactants to break down grease and stains without producing bubbles, making them suitable for applications where residue-free rinsing is critical. Performance comparison shows foaming agents excel in visible dirt and grime removal, while non-foaming agents provide superior results in precision cleaning and quick rinsing tasks.

Choosing the Right Agent for Your Cleaning Needs

Foaming agents enhance the cleaning process by creating bubbles that trap dirt and grease, making them ideal for surfaces requiring visible lather and effective grime removal. Non-foaming agents suit applications where residue-free rinsing is crucial, such as glass or electronics cleaning, ensuring a streak-free finish. Selecting between foaming and non-foaming agents depends on the surface type, cleaning goals, and the need for residue visibility during the process.

Foaming agent vs Non-foaming agent Infographic

productdif.com

productdif.com