Foam cleaning offers superior adherence to vertical surfaces and deep penetration into crevices, making it ideal for tackling stubborn dirt and grime. Liquid cleaning provides faster application and rinsing, perfect for large, flat areas requiring quick and efficient coverage. Choosing between foam and liquid cleaning depends on the surface type and the level of cleaning intensity needed.

Table of Comparison

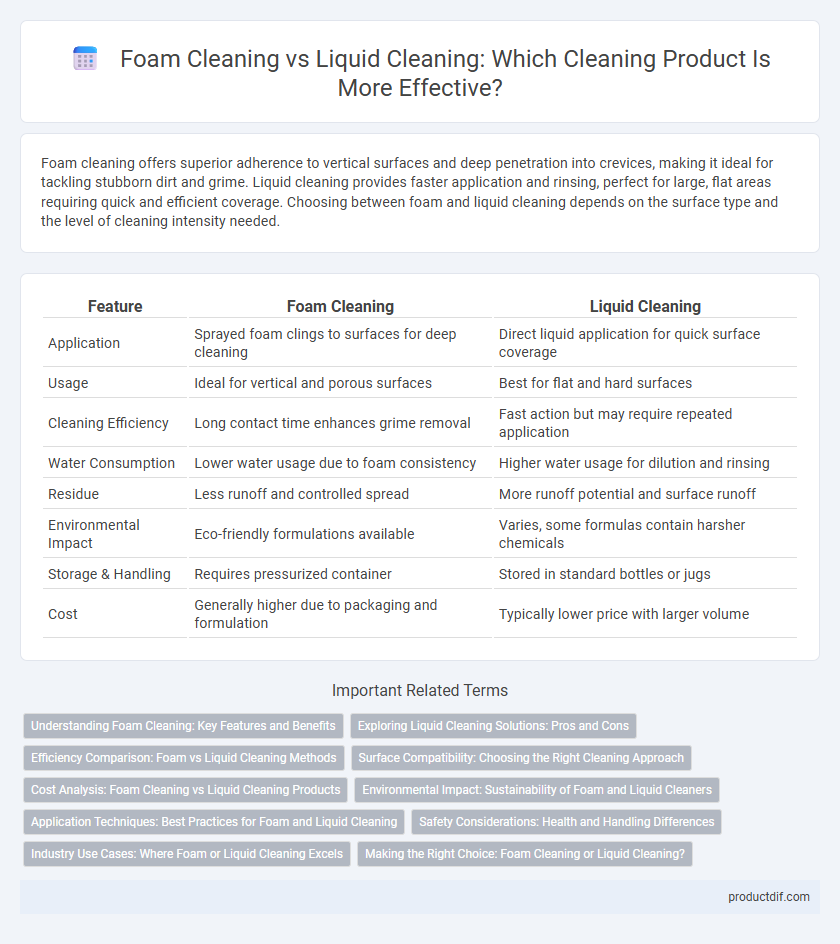

| Feature | Foam Cleaning | Liquid Cleaning |

|---|---|---|

| Application | Sprayed foam clings to surfaces for deep cleaning | Direct liquid application for quick surface coverage |

| Usage | Ideal for vertical and porous surfaces | Best for flat and hard surfaces |

| Cleaning Efficiency | Long contact time enhances grime removal | Fast action but may require repeated application |

| Water Consumption | Lower water usage due to foam consistency | Higher water usage for dilution and rinsing |

| Residue | Less runoff and controlled spread | More runoff potential and surface runoff |

| Environmental Impact | Eco-friendly formulations available | Varies, some formulas contain harsher chemicals |

| Storage & Handling | Requires pressurized container | Stored in standard bottles or jugs |

| Cost | Generally higher due to packaging and formulation | Typically lower price with larger volume |

Understanding Foam Cleaning: Key Features and Benefits

Foam cleaning products offer superior adherence to vertical and irregular surfaces, enhancing contact time and improving dirt and grime removal compared to liquid cleaners. The thick foam matrix traps and lifts contaminants effectively while reducing runoff and chemical usage, making it ideal for targeted cleaning tasks. Foam cleaners also provide visible application control, ensuring thorough coverage and efficient use of cleaning agents.

Exploring Liquid Cleaning Solutions: Pros and Cons

Liquid cleaning solutions offer excellent versatility and deep penetration for removing dirt and grime from various surfaces, making them ideal for both household and industrial use. Their quick application and absorption enhance cleaning efficiency, but they can sometimes leave residues or require rinsing, which may not be suitable for all materials. While liquids can cover large areas efficiently, they also pose challenges such as potential spillage and longer drying times compared to foam cleaning.

Efficiency Comparison: Foam vs Liquid Cleaning Methods

Foam cleaning offers superior adherence to vertical and uneven surfaces, allowing longer contact time and enhanced removal of dirt and grease compared to liquid cleaning, which tends to run off quickly. Liquid cleaning methods provide faster coverage on large flat areas but may require more frequent application to maintain effectiveness. Efficiency in cleaning depends on the surface type, with foam being ideal for targeted, high-residue areas and liquid solutions better suited for broad, less soiled surfaces.

Surface Compatibility: Choosing the Right Cleaning Approach

Foam cleaning offers superior surface compatibility by gently adhering to vertical and delicate surfaces, reducing runoff and minimizing damage on materials like wood, fabric, and electronics. Liquid cleaning excels on hard, non-porous surfaces such as tiles and glass, providing deep penetration and efficient removal of stubborn stains. Selecting the appropriate cleaning approach depends on the surface type, where foam solutions protect sensitive finishes and liquids optimize cleaning power on durable surfaces.

Cost Analysis: Foam Cleaning vs Liquid Cleaning Products

Foam cleaning products generally offer cost advantages due to reduced product usage and minimized waste compared to liquid cleaners, which often require larger quantities and can lead to higher consumption rates. The concentrated nature of foam formulations allows for more efficient application, lowering overall material and labor costs in commercial and industrial settings. Liquid cleaning products may incur additional expenses related to storage and handling, whereas foam cleaners typically reduce these overheads through easier, more controlled dispensing systems.

Environmental Impact: Sustainability of Foam and Liquid Cleaners

Foam cleaners typically use less water and generate less runoff compared to liquid cleaners, reducing the environmental burden during cleaning processes. Liquid cleaners often contain higher concentrations of chemicals and packaging waste, which can contribute to pollution and landfill volume if not properly managed. The sustainability of foam versus liquid cleaning products depends largely on formulation, packaging, and disposal practices, with eco-friendly ingredients and recyclable containers enhancing environmental benefits.

Application Techniques: Best Practices for Foam and Liquid Cleaning

Foam cleaning ensures better surface adherence and controlled application, making it ideal for vertical surfaces and hard-to-reach areas, while liquid cleaning allows for faster coverage and is effective for extensive horizontal surfaces. Best practices for foam cleaning include applying a thick, even layer to maximize contact time and using low-pressure spray systems to avoid foam collapse. For liquid cleaning, optimal techniques involve using high-pressure sprays with agitation tools to enhance soil removal and thorough rinsing to prevent residue buildup.

Safety Considerations: Health and Handling Differences

Foam cleaning products minimize airborne chemical exposure, reducing inhalation risks compared to liquid cleaners, which can release volatile compounds during application. Foam formulations often cling to surfaces longer, enabling effective cleaning with less frequent reapplication and minimizing skin contact hazards. Proper handling of foam cleaners requires attention to texture and residue, whereas liquid cleaners demand careful dilution and storage to prevent accidental spills and chemical burns.

Industry Use Cases: Where Foam or Liquid Cleaning Excels

Foam cleaning excels in industrial use cases requiring precise application and minimal runoff, such as food processing plants and pharmaceutical manufacturing, where surface adherence and controlled coverage are critical. Liquid cleaning solutions dominate in heavy-duty applications like machinery maintenance and oil refineries due to their ability to penetrate deep into crevices and dissolve stubborn residues efficiently. Industries prioritize foam for sanitization and containment while selecting liquid cleaners for comprehensive degreasing and heavy soil removal.

Making the Right Choice: Foam Cleaning or Liquid Cleaning?

Foam cleaning offers superior adherence to vertical surfaces and better control in targeted applications, making it ideal for deep cleaning and sanitizing in industrial kitchens or healthcare settings. Liquid cleaning solutions provide faster coverage and penetration for large surface areas, optimal for routine cleaning tasks in offices or homes. Choosing between foam and liquid cleaning depends on surface type, cleaning goals, and desired contact time for effective germ removal.

Foam Cleaning vs Liquid Cleaning Infographic

productdif.com

productdif.com