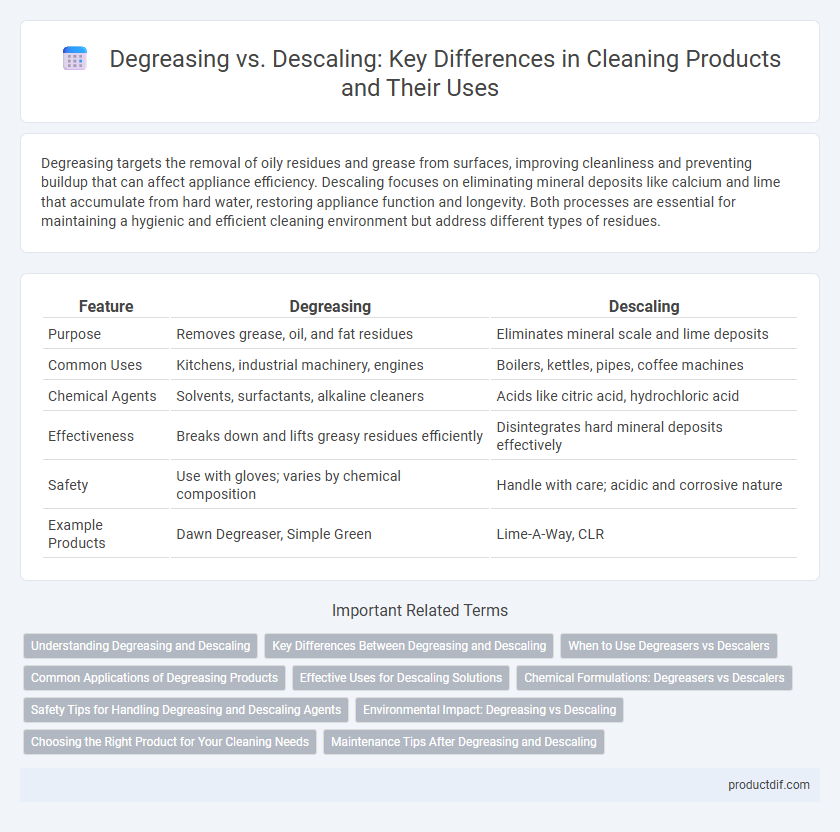

Degreasing targets the removal of oily residues and grease from surfaces, improving cleanliness and preventing buildup that can affect appliance efficiency. Descaling focuses on eliminating mineral deposits like calcium and lime that accumulate from hard water, restoring appliance function and longevity. Both processes are essential for maintaining a hygienic and efficient cleaning environment but address different types of residues.

Table of Comparison

| Feature | Degreasing | Descaling |

|---|---|---|

| Purpose | Removes grease, oil, and fat residues | Eliminates mineral scale and lime deposits |

| Common Uses | Kitchens, industrial machinery, engines | Boilers, kettles, pipes, coffee machines |

| Chemical Agents | Solvents, surfactants, alkaline cleaners | Acids like citric acid, hydrochloric acid |

| Effectiveness | Breaks down and lifts greasy residues efficiently | Disintegrates hard mineral deposits effectively |

| Safety | Use with gloves; varies by chemical composition | Handle with care; acidic and corrosive nature |

| Example Products | Dawn Degreaser, Simple Green | Lime-A-Way, CLR |

Understanding Degreasing and Descaling

Degreasing involves removing oil, grease, and oily residues from surfaces using solvents or detergents specifically formulated to break down lipids. Descaling targets the elimination of mineral deposits such as limescale and calcium buildup commonly found in appliances exposed to hard water. Understanding the chemical nature and intended surface area for each process ensures optimal cleaning effectiveness and prolongs equipment lifespan.

Key Differences Between Degreasing and Descaling

Degreasing targets the removal of oily, greasy residues using solvents or alkaline cleaners, essential for kitchen appliances and automotive parts. Descaling removes mineral deposits and limescale buildup caused by hard water, primarily utilizing acids like citric or hydrochloric acid for effective scale dissolution. The key difference lies in the substances they eliminate--organic grease versus inorganic mineral scale--requiring distinct chemical formulations and cleaning methods tailored to specific residue types.

When to Use Degreasers vs Descalers

Degreasers are ideal for removing oil, grease, and heavy soils from kitchen surfaces, machinery, and automotive parts, making them essential in environments with oily residues. Descalers are specifically formulated to break down mineral deposits such as limescale and calcium buildup in appliances like kettles, boilers, and coffee machines. Use degreasers when tackling organic grime and oil-based stains, while descalers are necessary for maintaining efficiency by eliminating hard water scale and mineral deposits.

Common Applications of Degreasing Products

Degreasing products are commonly used in industrial kitchens, automotive workshops, and manufacturing plants to remove heavy grease, oil, and dirt from surfaces such as machinery, engines, and floors. These products contain powerful solvents and surfactants that break down oily residues, improving equipment efficiency and hygiene. Unlike descaling agents, which target mineral deposits and limescale buildup, degreasers focus on eliminating organic oils and greasy contaminants.

Effective Uses for Descaling Solutions

Descaling solutions effectively remove mineral deposits and limescale buildup from surfaces such as kettles, coffee machines, and pipes, restoring optimal function and prolonging appliance life. These solutions typically contain acids like citric acid or sulfamic acid that dissolve hard water residues without damaging metal or ceramic parts. Using descaling products regularly prevents clogging and improves heat transfer efficiency, making them essential for maintaining household and industrial equipment exposed to hard water.

Chemical Formulations: Degreasers vs Descalers

Degreasers contain surfactants and solvents that break down oils, grease, and fats by emulsification, facilitating removal from surfaces. Descalers incorporate acidic compounds such as sulfuric or citric acid that chemically dissolve mineral deposits like limescale and calcium buildup. These chemical formulations target distinct residues, making degreasers ideal for organic grime and descalers essential for inorganic mineral scaling.

Safety Tips for Handling Degreasing and Descaling Agents

Degreasing agents often contain strong solvents that require the use of gloves and proper ventilation to prevent skin irritation and inhalation hazards. Descaling agents typically include acids that can cause burns; therefore, wearing protective eyewear and avoiding direct contact is essential for safe handling. Proper storage in labeled containers away from incompatible substances reduces the risk of chemical reactions and ensures workplace safety.

Environmental Impact: Degreasing vs Descaling

Degreasing products often contain harsh solvents that can contribute to water pollution and harm aquatic ecosystems, whereas descaling agents typically use acids that may be biodegradable but still pose risks if improperly disposed. Choosing environmentally friendly degreasers with bio-based ingredients reduces toxic runoff, while using milder descalers limits the release of corrosive substances into the environment. Proper disposal and selecting non-toxic, eco-certified cleaning products minimize the overall environmental impact of both degreasing and descaling processes.

Choosing the Right Product for Your Cleaning Needs

Degreasing targets the removal of oil, grease, and sticky residues often found in kitchens and machinery, making it essential for surfaces exposed to heavy oils. Descaling focuses on eliminating mineral deposits like limescale caused by hard water, crucial for appliances such as kettles, coffee makers, and pipes. Selecting the right product depends on the type of buildup--use degreasers for oily grime and descalers for mineral residue--to ensure effective and safe cleaning outcomes.

Maintenance Tips After Degreasing and Descaling

After degreasing, ensure surfaces are thoroughly rinsed with warm water to remove any residual cleaning agents, preventing buildup or corrosion. Following descaling, apply a protective coating or sealant to inhibit mineral deposits and extend equipment lifespan. Regular inspection and prompt cleaning help maintain optimal performance and avoid damage caused by grease or scale accumulation.

Degreasing vs Descaling Infographic

productdif.com

productdif.com