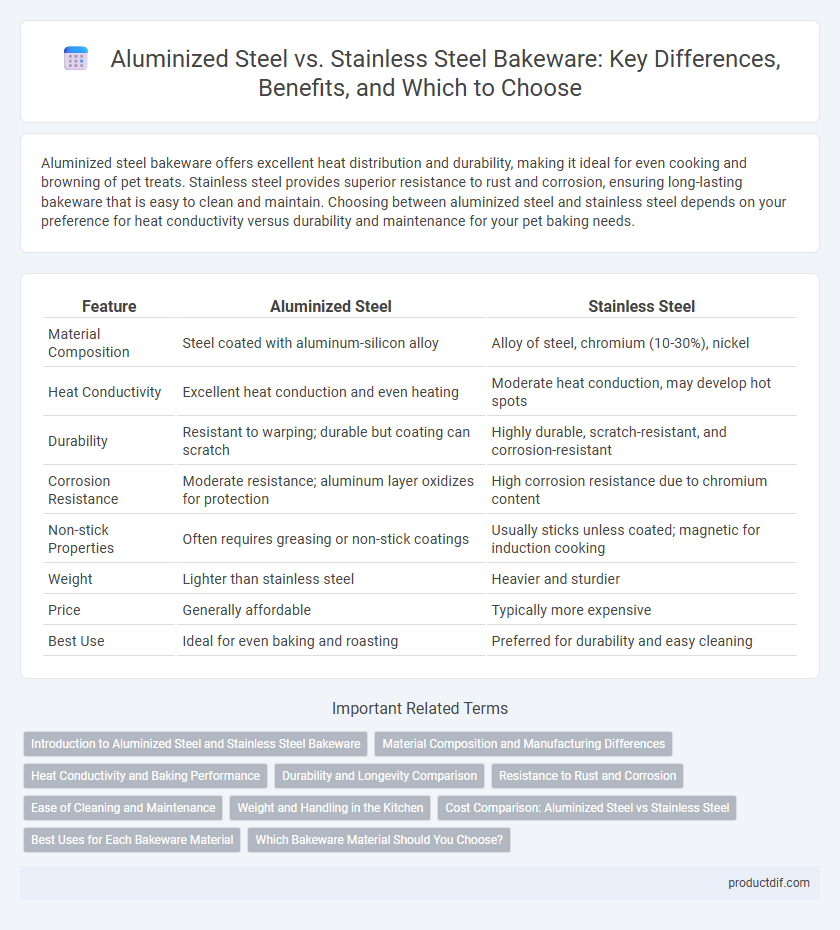

Aluminized steel bakeware offers excellent heat distribution and durability, making it ideal for even cooking and browning of pet treats. Stainless steel provides superior resistance to rust and corrosion, ensuring long-lasting bakeware that is easy to clean and maintain. Choosing between aluminized steel and stainless steel depends on your preference for heat conductivity versus durability and maintenance for your pet baking needs.

Table of Comparison

| Feature | Aluminized Steel | Stainless Steel |

|---|---|---|

| Material Composition | Steel coated with aluminum-silicon alloy | Alloy of steel, chromium (10-30%), nickel |

| Heat Conductivity | Excellent heat conduction and even heating | Moderate heat conduction, may develop hot spots |

| Durability | Resistant to warping; durable but coating can scratch | Highly durable, scratch-resistant, and corrosion-resistant |

| Corrosion Resistance | Moderate resistance; aluminum layer oxidizes for protection | High corrosion resistance due to chromium content |

| Non-stick Properties | Often requires greasing or non-stick coatings | Usually sticks unless coated; magnetic for induction cooking |

| Weight | Lighter than stainless steel | Heavier and sturdier |

| Price | Generally affordable | Typically more expensive |

| Best Use | Ideal for even baking and roasting | Preferred for durability and easy cleaning |

Introduction to Aluminized Steel and Stainless Steel Bakeware

Aluminized steel bakeware combines the strength of steel with an aluminum coating that enhances heat conduction and resists rust, making it ideal for even baking and durability. Stainless steel bakeware features a non-reactive surface with excellent corrosion resistance and durability, often preferred for its sleek appearance and ease of maintenance. Both materials offer distinct advantages in heat distribution and longevity, catering to different baking preferences and needs.

Material Composition and Manufacturing Differences

Aluminized steel consists of a steel core coated with an aluminum-silicon alloy, providing superior heat distribution and corrosion resistance, while stainless steel is an alloy primarily composed of iron, chromium, and nickel, offering exceptional durability and rust resistance. Manufacturing aluminized steel involves a hot-dip coating process to bond the aluminum layer onto the steel substrate, enhancing thermal conductivity and longevity. In contrast, stainless steel is produced through alloying and cold working processes, creating a dense, non-reactive surface ideal for bakeware that withstands high temperatures and resists staining.

Heat Conductivity and Baking Performance

Aluminized steel offers superior heat conductivity compared to stainless steel, ensuring more even baking and browning of baked goods. Its aluminum coating distributes heat quickly and prevents hot spots, which enhances overall baking performance. Stainless steel, while durable and resistant to corrosion, conducts heat less efficiently, potentially leading to uneven cooking results.

Durability and Longevity Comparison

Aluminized steel bakeware offers excellent heat distribution and resistance to corrosion, maintaining durability through repeated use and exposure to high temperatures. Stainless steel bakeware excels in longevity due to its non-reactive surface and superior resistance to rust and warping under frequent washing and oven cycles. While aluminized steel provides good durability, stainless steel bakeware is often preferred for its long-lasting performance and minimal maintenance requirements.

Resistance to Rust and Corrosion

Aluminized steel offers excellent resistance to rust and corrosion due to its aluminum-silicon alloy coating, which forms a protective barrier against moisture and oxidation. Stainless steel contains chromium that forms a passive layer, preventing rust and corrosion while maintaining durability under high temperatures. Both materials provide strong resistance, but aluminized steel typically delivers enhanced protection in humid or acidic baking environments.

Ease of Cleaning and Maintenance

Aluminized steel bakeware features a smooth, non-porous surface that resists sticking and simplifies cleaning, often requiring only a gentle scrub with mild detergent. Stainless steel bakeware is highly durable and resists rust and corrosion but can require more effort to remove baked-on residues due to its harder surface. Both materials benefit from hand washing to preserve finish quality, but aluminized steel generally offers a quicker and more effortless maintenance experience.

Weight and Handling in the Kitchen

Aluminized steel bakeware is lighter than stainless steel, making it easier to handle and maneuver in the kitchen. The reduced weight helps reduce fatigue during extended baking sessions and allows for quicker adjustments when placing or removing pans from ovens. Stainless steel, while heavier, offers durability but requires more careful handling due to its weight.

Cost Comparison: Aluminized Steel vs Stainless Steel

Aluminized steel bakeware is typically more affordable than stainless steel, making it a cost-effective choice for home bakers and professionals seeking durability without a high price tag. Stainless steel bakeware offers superior corrosion resistance and a sleek finish, but these benefits come at a premium, often costing significantly more than aluminized steel options. Budget-conscious consumers prioritize aluminized steel for its excellent heat conductivity and reasonable price, while those focusing on longevity and aesthetics may invest in pricier stainless steel bakeware.

Best Uses for Each Bakeware Material

Aluminized steel bakeware excels in heat conductivity and even baking, making it ideal for cookies, pastries, and browning tasks where consistent temperature is crucial. Stainless steel bakeware offers superior durability and resistance to corrosion, making it perfect for roasting meats and baking dishes that require prolonged exposure to moisture and acidic ingredients. Each material serves distinct baking needs, with aluminized steel optimizing heat performance and stainless steel ensuring longevity and structural integrity.

Which Bakeware Material Should You Choose?

Aluminized steel bakeware offers excellent heat conductivity and even baking, making it ideal for cookies and pastries, while stainless steel bakeware provides superior durability and resistance to rust, perfect for roasting and heavy-duty use. Consider aluminized steel if you prioritize quick, consistent browning and lightweight pans; select stainless steel for long-lasting, versatile cookware that requires less maintenance. Both materials offer unique benefits, so choosing depends on your baking style and frequency of use.

Aluminized Steel vs Stainless Steel Infographic

productdif.com

productdif.com