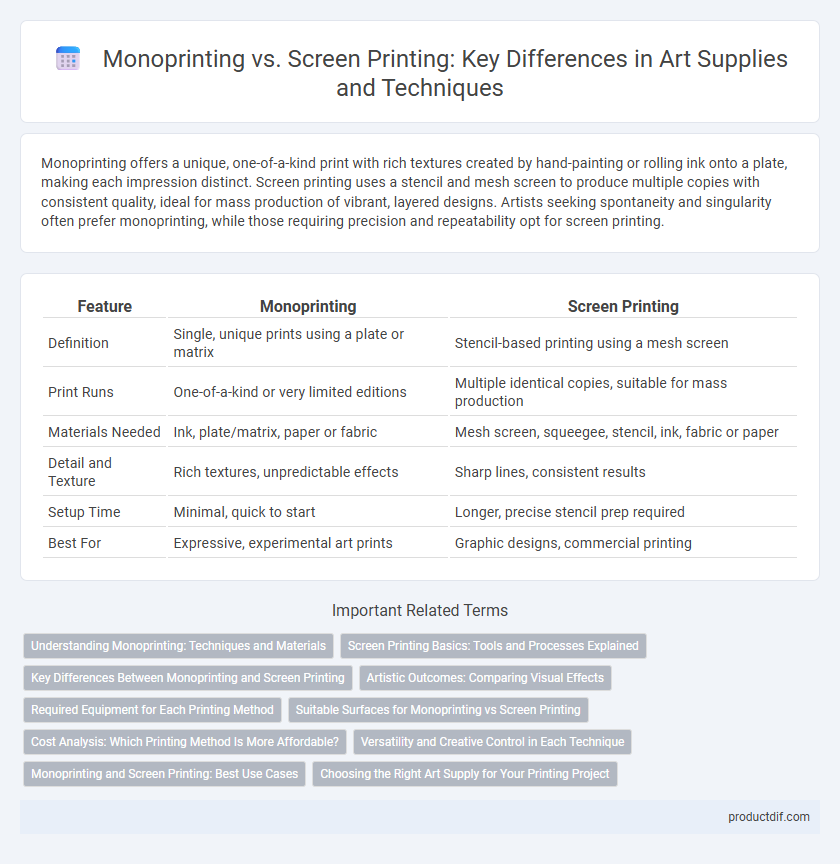

Monoprinting offers a unique, one-of-a-kind print with rich textures created by hand-painting or rolling ink onto a plate, making each impression distinct. Screen printing uses a stencil and mesh screen to produce multiple copies with consistent quality, ideal for mass production of vibrant, layered designs. Artists seeking spontaneity and singularity often prefer monoprinting, while those requiring precision and repeatability opt for screen printing.

Table of Comparison

| Feature | Monoprinting | Screen Printing |

|---|---|---|

| Definition | Single, unique prints using a plate or matrix | Stencil-based printing using a mesh screen |

| Print Runs | One-of-a-kind or very limited editions | Multiple identical copies, suitable for mass production |

| Materials Needed | Ink, plate/matrix, paper or fabric | Mesh screen, squeegee, stencil, ink, fabric or paper |

| Detail and Texture | Rich textures, unpredictable effects | Sharp lines, consistent results |

| Setup Time | Minimal, quick to start | Longer, precise stencil prep required |

| Best For | Expressive, experimental art prints | Graphic designs, commercial printing |

Understanding Monoprinting: Techniques and Materials

Monoprinting involves creating unique prints using a single impression from a painted or inked plate, emphasizing spontaneity and textural variation. Techniques often include applying ink to a smooth surface like plexiglass or metal, using brushes, rollers, or stencils, and transferring the image onto paper with a printing press or by hand. Key materials for monoprinting are water-based or oil-based inks, brayers, printing plates, and high-quality printmaking paper, enabling artists to explore one-of-a-kind designs distinct from the repeatability of screen printing.

Screen Printing Basics: Tools and Processes Explained

Screen printing involves forcing ink through a mesh stencil onto a surface, typically fabric or paper, using a squeegee to create vibrant and durable designs. Essential tools include a mesh screen, emulsion, a squeegee, and inks formulated for different materials, while the process requires coating the screen with emulsion, exposing it to light with the desired design, and then printing by pressing ink through the stencil. This method offers precise control over color application and is favored for its versatility in producing multiple copies with consistent quality.

Key Differences Between Monoprinting and Screen Printing

Monoprinting offers unique, one-of-a-kind prints with each press due to its direct application of ink on the plate, while screen printing produces consistent, repeatable designs using a mesh stencil and squeegee. Monoprinting allows for more experimental textures and color blending, whereas screen printing excels in sharp, vibrant, and uniform graphics, ideal for mass production. The equipment complexity and setup time differ significantly; monoprinting requires minimal tools, making it accessible for spontaneous creativity, while screen printing demands precise screens and preparation for multiple layers.

Artistic Outcomes: Comparing Visual Effects

Monoprinting produces unique, one-of-a-kind prints characterized by rich textures and spontaneous color blending, resulting in highly expressive and organic visual effects. Screen printing enables consistent, vibrant color layering with sharp edges and graphic clarity, ideal for bold and repetitive designs. Artists often choose monoprinting for experimental, textured aesthetics, while screen printing excels in precise patterns and repeatability.

Required Equipment for Each Printing Method

Monoprinting requires minimal equipment, typically including a brayer, a smooth printing plate such as plexiglass or metal, and water-based or oil-based inks, making it ideal for artists seeking a straightforward and flexible process. Screen printing demands more specialized tools, such as a mesh screen stretched over a frame, a squeegee for ink application, and emulsion for stencil creation, alongside a light source for exposing the screen. Both methods require specific inks, but screen printing inks are generally thicker and designed to pass through mesh, while monoprinting inks prioritize transfer quality onto various paper types.

Suitable Surfaces for Monoprinting vs Screen Printing

Monoprinting excels on non-porous surfaces like glass, metal, and smooth paper due to its direct painting technique, allowing for unique, textured impressions with each print. Screen printing is highly versatile and ideal for fabric, paper, wood, and even plastic, as it uses stencils to transfer ink through a mesh screen, creating consistent and vibrant designs. Choosing between these methods depends on the surface texture and the desired print quality, with monoprinting offering spontaneity on flat, smooth surfaces and screen printing providing durability on various textured materials.

Cost Analysis: Which Printing Method Is More Affordable?

Monoprinting typically involves lower initial costs due to minimal equipment requirements, making it more affordable for beginners and small-scale projects. Screen printing demands investment in screens, pumps, and drying equipment, leading to higher upfront expenses but becoming cost-effective for large print runs due to economies of scale. Overall, monoprinting suits artists prioritizing low-cost, one-off prints, while screen printing offers better cost efficiency for bulk production.

Versatility and Creative Control in Each Technique

Monoprinting offers unparalleled versatility by allowing unique, one-of-a-kind prints through direct manipulation of ink and texture on a plate, enabling artists to experiment freely with colors and forms. Screen printing provides greater creative control in producing consistent, repeatable images with sharp lines and vibrant colors, ideal for multiple-copy projects and precise layering. Each technique balances flexibility and precision differently, catering to distinct artistic goals and workflows.

Monoprinting and Screen Printing: Best Use Cases

Monoprinting excels in creating unique, one-of-a-kind artworks with unpredictable textures and spontaneous effects, making it ideal for experimental and small-batch projects. Screen printing suits reproducing consistent, vibrant designs on textiles, posters, and merchandise, offering scalability and precision for commercial and graphic art applications. Artists choose monoprinting for creative exploration and individuality, while screen printing is favored for mass production and sharp detail replication.

Choosing the Right Art Supply for Your Printing Project

Monoprinting requires versatile inks and textured paper that enhance unique, one-of-a-kind prints, making it ideal for experimental art projects. Screen printing demands durable, opaque inks and fine mesh screens to achieve consistent, repeatable designs on various surfaces such as fabric, paper, or wood. Selecting high-quality acrylic-based inks and pressure tools tailored to your technique ensures vibrant colors and sharp details, optimizing your printmaking workflow.

Monoprinting vs Screen Printing Infographic

productdif.com

productdif.com